Parent page: Capturing Your Design Idea as a Schematic

When schematics were originally captured on paper, it was often on a single sheet of paper large enough to fill a big drafting table, which was reproduced on a dedicated, large-format copier. Times have changed, now schematics are captured on a desktop PC, stored on a server, and printed on a small-format laser printer.

This change means that even a simple design can be more easily displayed and understood if it is presented on multiple schematic sheets. Even when the design is not particularly complicated, there can be advantages in organizing it across multiple sheets.

For example, the design may include various modular elements. Maintaining these modules as individual documents allows several designers to work on a project at the same time. Breaking the design into logical modules greatly enhances the readability of the design too, an important consideration for those that need to read and interpret the schematic later in the life of that product. Another advantage is that when a design is structured over a number of sheets with fewer components on each, small format printing, such as laser printers, can be used.

There are two decisions to make if you plan to spread your design over multiple sheets:

- the structural relationship of the sheets, and

- the method employed for electrical connectivity between the circuitry on those sheets.

Your choice will vary according to the size and type of each project, and your personal preferences.

This article focuses on the structural relationships between the sheets, how it works, and the tools and techniques available to create a multi-sheet design. To learn more about how connectivity is created, refer to the Creating Connectivity article.

Flat or Hierarchical Design

As mentioned, as the designer you need to decide how the schematic sheets are organized, and how the connectivity is established between those sheets. These are not separate decisions though, as you choose the structure you will also need to choose how the connections between those sheets are going to be created.

There are two approaches to structuring a multi-sheet design: either flat or hierarchical.

The technique used to connect a child sheet to the parent sheet is the same for both flat and hierarchical designs - it is how the connectivity is created that determines if it is a flat or hierarchical design.

Flat Design

You can think of a flat design as if a large schematic sheet has been cut up into a number of smaller sheets - in a flat design all sheets exist on the same level. The connectivity in a flat design is created directly from any sheet to any other sheet - this type of connectivity is referred to as horizontal connectivity.

The use of a top sheet is optional in a flat design. If one is included, it will have a sheet symbol for each of the sheets in the design, but cannot include any wiring. There can be any number of sheets in a flat design.

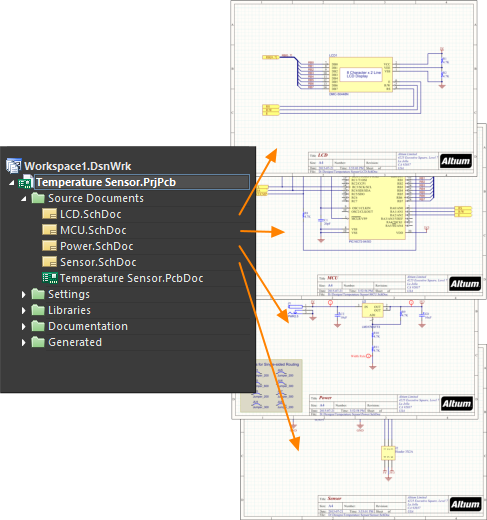

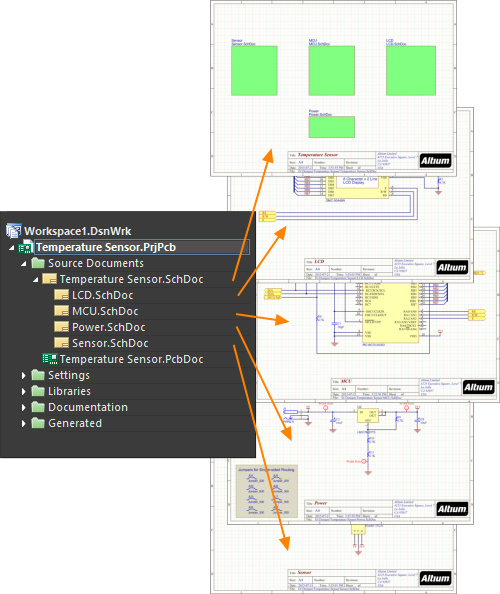

First image - the flat design has no top sheet; second image - the same design has a top sheet. Note that the top sheet has no wiring. It simply shows the sheets in the design.

Both of the images above show a flat design, the version on the left does not have a top sheet, the version on the right does. For a small design that only has two or three schematic sheets in it, you might decide that a top sheet does not add any value. Once the sheet count gets higher, a top sheet can help the reader understand the functionality of the circuit design from the way that the logical blocks (Sheet Symbols) are arranged on the sheet. All sheets in the design appear at the same level in the Projects panel because there is no hierarchy.

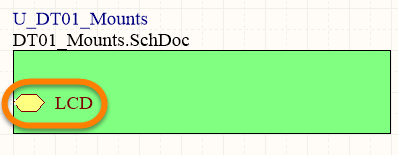

Sheet SymbolExpandCollapse

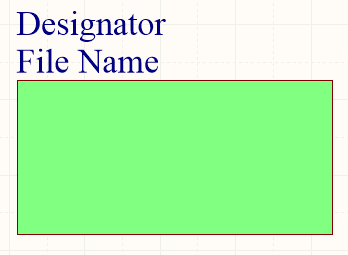

A placed Sheet Symbol

Summary

A sheet symbol is an electrical design primitive. It is used to represent a sub-sheet in a multi-sheet hierarchical design. Sheet symbols include sheet entry symbols, which provide a connection point for signals between the parent and child sheets in a hierarchical design, similar to the way that Ports provide connections between sheets in a flat-sheet design.

Availability

Sheet symbols are available for placement in the Schematic Editor only. Use one of the following methods to access the placement command:

- Choose Place » Sheet Symbol from the main menus.

- Click the Sheet Symbol button (

) in the graphic objects drop-down on the Active Bar located at the top of the design space. (Click and hold an Active Bar button to access other related commands. Once a command has been used, it will become the top-most item on that section of the Active Bar.)

) in the graphic objects drop-down on the Active Bar located at the top of the design space. (Click and hold an Active Bar button to access other related commands. Once a command has been used, it will become the top-most item on that section of the Active Bar.)

- Right-click in the design space then choose Place » Sheet Symbol from the context menu.

- Click

on the Wiring toolbar.

on the Wiring toolbar.

Placement

After launching the command, the cursor will change to a cross-hair and enter sheet symbol placement mode. Placement is made by performing the following actions:

- Click or press Enter to anchor the first corner of the sheet symbol.

- Move the cursor to adjust the size of the sheet symbol then click or press Enter to complete placement.

- Continue placing further sheet symbols or right-click or press Esc to exit placement mode.

Additional actions that can be performed during placement while the sheet symbol is still floating on the cursor and before its first corner is anchored are:

- Press the Tab key to access the Sheet Symbol mode of the Properties panel from where properties for the sheet symbol can be changed on the fly. Click the design space pause button overlay (

) to resume placement.

) to resume placement.

- Press and hold the Alt key to constrain the direction of movement to the horizontal or vertical axis depending on the initial direction of movement.

- Press the Spacebar to rotate the sheet symbol counterclockwise or Shift+Spacebar for clockwise rotation. Rotation is in increments of 90°.

- Press the X or Y keys to mirror the sheet symbol along the X-axis or Y-axis.

While attributes can be modified during placement (

Tab to access the

Properties panel), keep in mind that these will become the default settings for further placement unless the

Permanent option on the

Schematic – Defaults page of the

Preferences dialog is enabled. When this option is enabled, changes made will affect only the object being placed and subsequent objects placed during the same placement session.

Graphical Editing

This method of editing allows you to select a placed sheet symbol object directly in the design space and graphically change its size, shape or location.

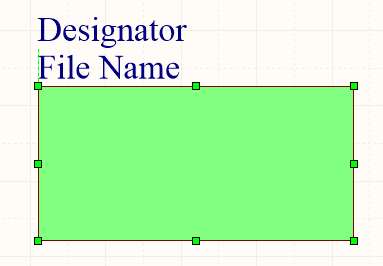

When a sheet symbol object is selected, you can click and drag the editing handles to resize the sheet symbol.

A selected Sheet Symbol

Click anywhere on the sheet symbol away from editing handles and drag to reposition it. While dragging, the sheet symbol can be rotated (Spacebar/Shift+Spacebar) or mirrored (X or Y keys to mirror along the X-axis or Y-axis).

Resizing the sheet symbol will not affect the absolute positions of any defined sheet entries within.

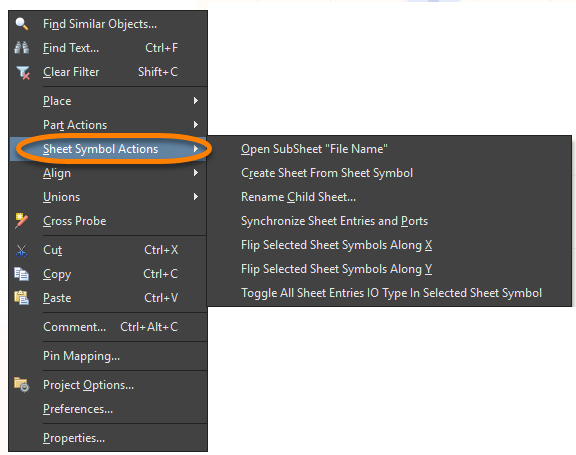

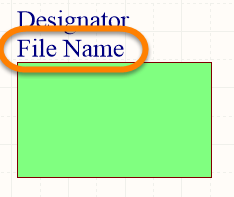

The sheet symbol's Designator and File Name text fields can only be resized by changing the size of the font used (accessed through the appropriate object's Properties panels). As such, editing handles are not available when either of those objects are selected.

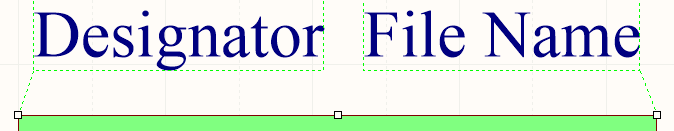

Selected Designator and Filename for a sheet symbol

- Click anywhere inside the dashed box and drag to reposition the text object as required. While dragging, the text can be rotated (Spacebar/Shift+Spacebar) or mirrored (X or Y keys to mirror along the X-axis or Y-axis).

- The text for an object can be edited in-place by:

- Single-clicking the designator or filename text to select it.

- Single-clicking again (or pressing Enter) to enter the in-place editing mode. Sufficient time between each click should be given to ensure the software does not interpret the two single-clicks as one double-click (which would open the associated Properties panel).

- To finish editing in-place text, press Enter or use the mouse to click away from the text object.

If attempting to graphically modify an object that has its Locked property enabled, a dialog will appear asking for confirmation to proceed with the edit. If the Protect Locked Objects option is enabled on the Schematic – Graphical Editing page of the Preferences dialog, and the Locked option for that design object is enabled as well, then that object cannot be selected or graphically edited. Click the locked object to select it then disable the Locked property in the List panel or disable the Protect Locked Objects option to graphically edit the object.

Non-Graphical Editing

The following methods of non-graphical editing are available.

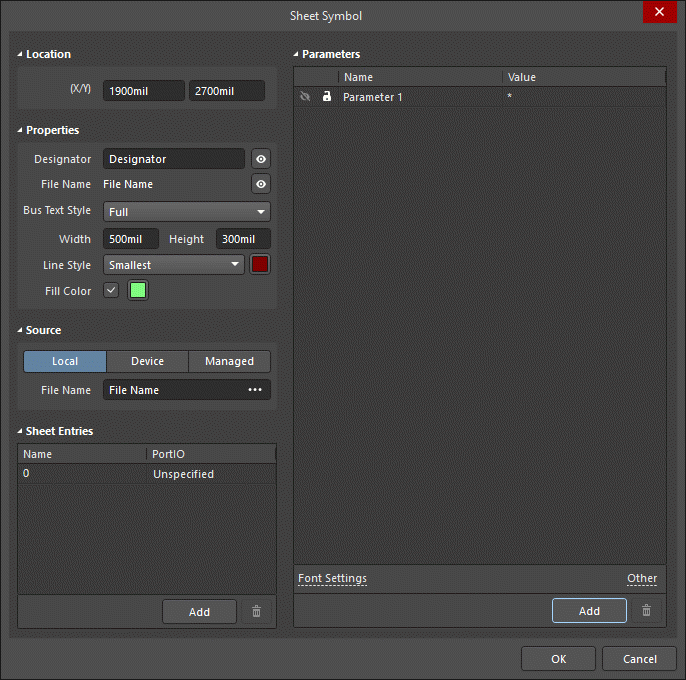

Editing via the Sheet Symbol Dialog or Properties Panel

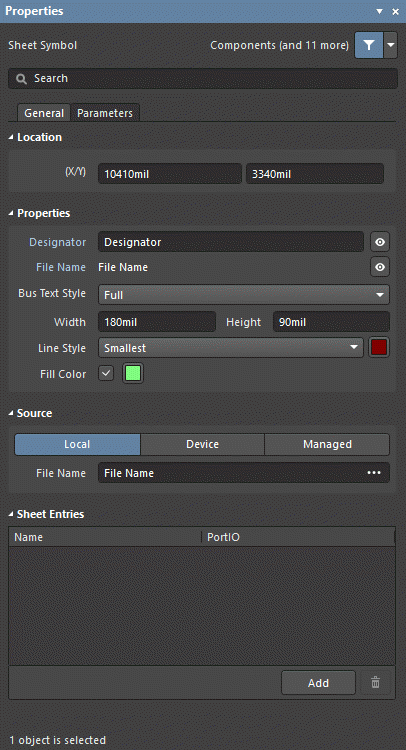

Properties page: Sheet Symbol Properties

This method of editing uses the associated Sheet Symbol dialog and the Properties panel mode to modify the properties of a sheet symbol object.

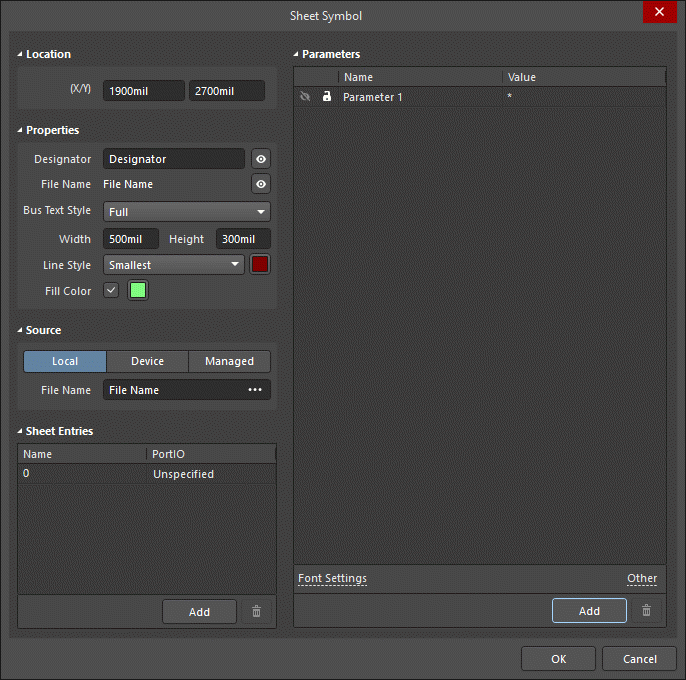

The Sheet Symbol dialog, on the left, and the Sheet Symbol mode of the Properties panel on the right

After placement, the Sheet Symbol dialog can be accessed by:

- Double-clicking on the placed sheet symbol object.

- Placing the cursor over the sheet symbol object, right-click, then choose Properties from the context menu.

During placement, the Sheet Symbol mode of the Properties panel can be accessed by pressing the Tab key. Once the sheet symbol is placed, all options appear.

After placement, the Sheet Symbol mode of the Properties panel can be accessed in one of the following ways:

- If the Properties panel is already active, by selecting the sheet symbol object.

- After selecting the sheet symbol object, select the Properties panel from the Panels button at the bottom right of the design space or select View » Panels » Properties.

If the

Double Click Runs Interactive Properties option is disabled (default) on the

Schematic - Graphical Editing page of the

Preferences dialog, when the primitive is double-clicked or you right-click on a selected primitive then choose

Properties, the dialog will open. When the

Double Click Runs Interactive Properties option is enabled, the

Properties panel will open.

While the options are the same in the dialog and the panel, the order and placement of the options may differ slightly.

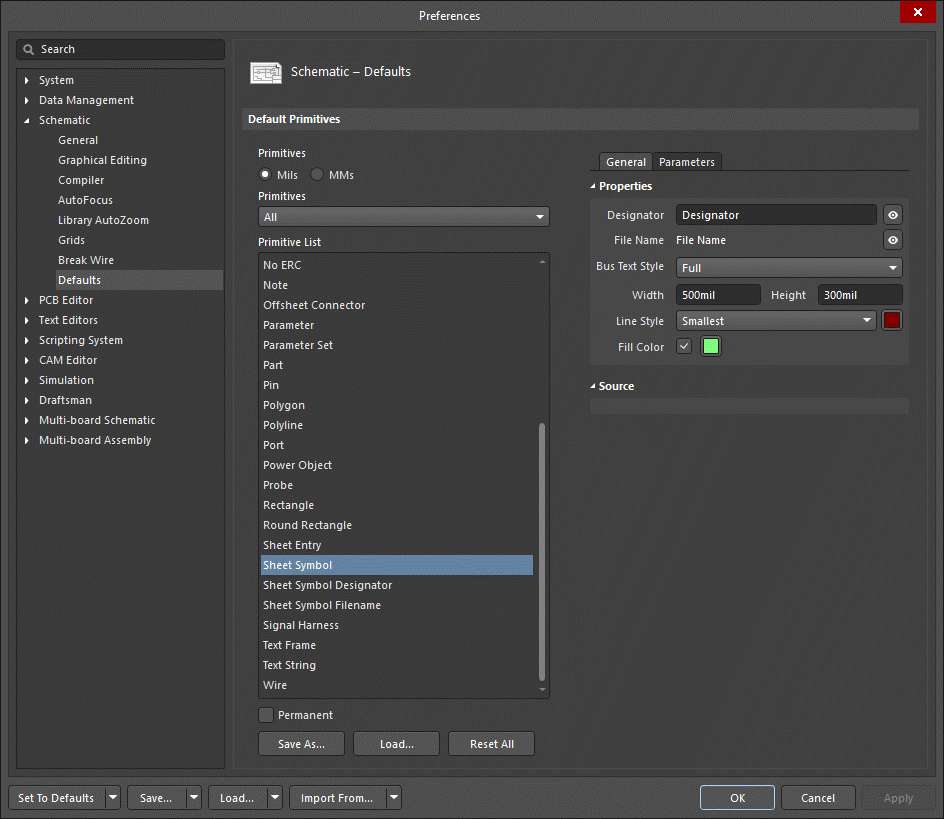

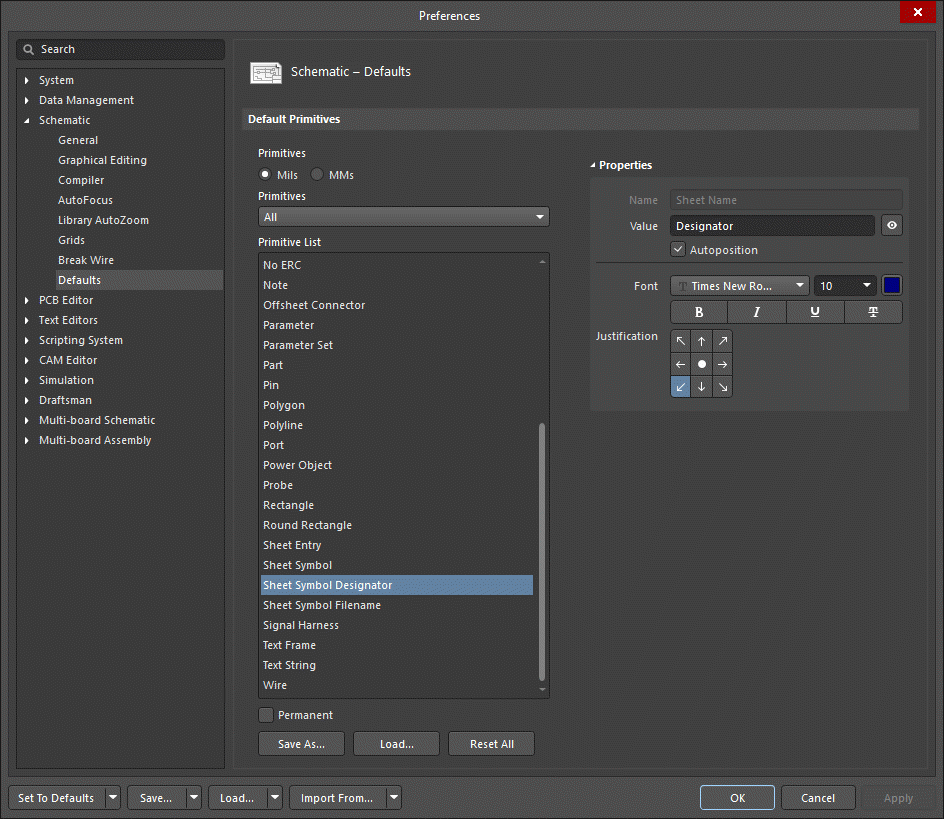

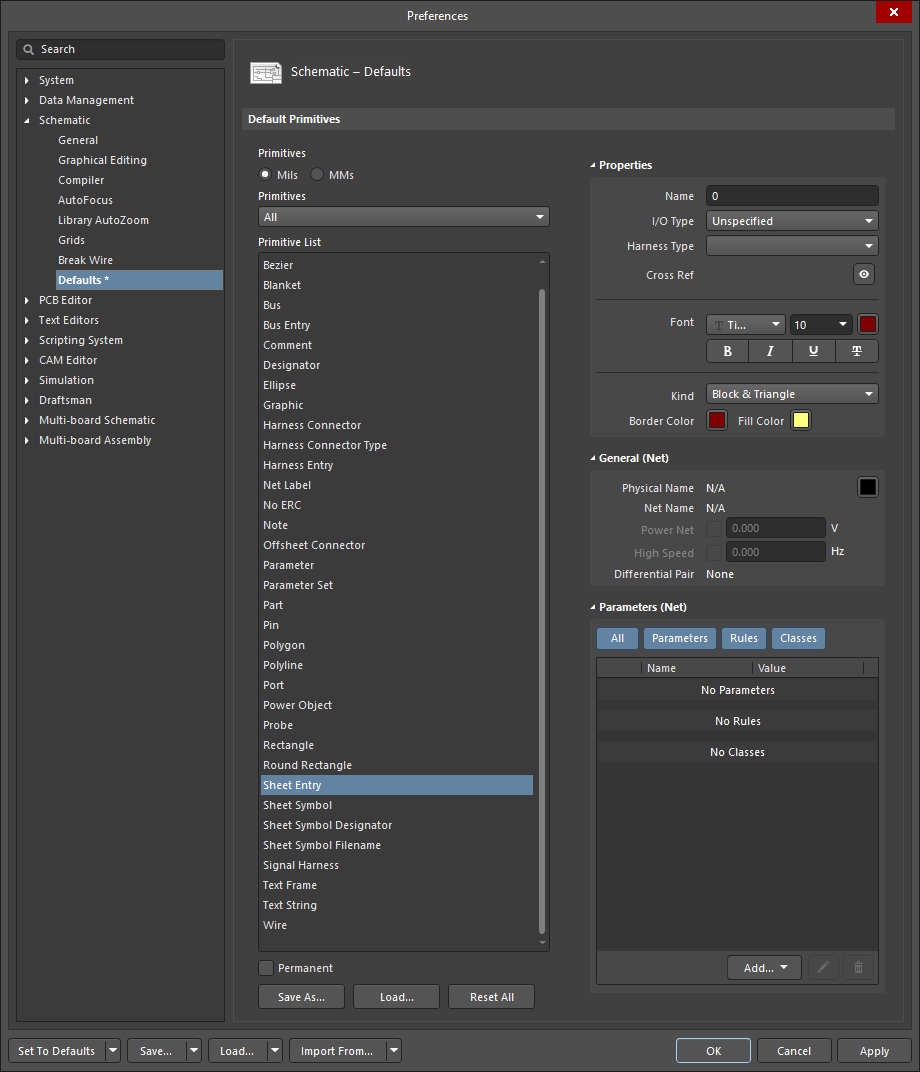

The sheet symbol properties can be accessed prior to entering placement mode from the

Schematic – Defaults page of the

Preferences dialog. This allows the default properties for the sheet symbol object to be changed, which will be applied when placing subsequent sheet symbols.

Editing Multiple Objects

The Properties panel supports multiple object editing, where the property settings that are identical in all currently selected objects may be modified. When multiples of the same object type are selected manually, via the Find Similar Objects dialog or through a SCH Filter or SCH List panel, a Properties panel field entry that is not shown as an asterisk (*) can be edited for all selected objects.

Editing via a List Panel

Panel pages: SCH List, SCH Filter

A List panel allows you to display design objects from one or more documents in tabular format, enabling quick inspection and modification of object attributes. Used in conjunction with appropriate filtering - by using the applicable Filter panel, or the Find Similar Objects dialog - it enables the display of just those objects falling under the scope of the active filter – allowing you to target and edit multiple design objects with greater accuracy and efficiency.

Sheet Symbol Actions

Formatting Designator and File Name

The sheet symbol Designator and File Name fields can be formatted independently of the sheet symbol. The corresponding Properties panels can be accessed using the after-placement methods described above (replacing sheet symbol with the relevant object whose properties you want to view/modify).

The

File Name of the sheet symbol (set in the

Sheet Symbol mode of the

Properties panel) must be set to the file name of the schematic sheet that the symbol represents.

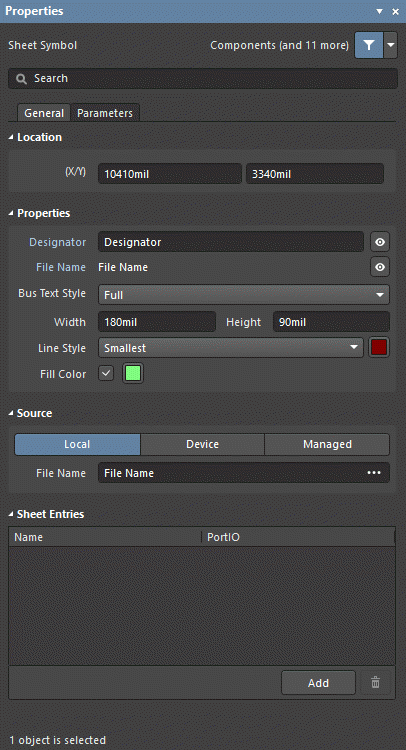

Right-click Sheet Symbol Commands

Right-click over a placed sheet symbol to access a context-sensitive menu, from which the following commands are available (on the Sheet Symbol Actions sub-menu) that act on that sheet symbol (or all currently selected sheet symbols, where applicable).

- Open SubSheet "<SheetName.SchDoc>" - use to access the child sheet referenced by the symbol, which will be opened (if not already) and made the active document in the main design window.

-

Create Sheet From Sheet Symbol - use to create a new schematic document from the sheet symbol and add ports to that document corresponding to each of the sheet entries on the symbol. In this way, you can automatically create the sub-sheets for a multi-sheet schematic design based on the sheet symbols you have created and placed on the top sheet.

The schematic document that is created is named using the entry in the sheet symbol's File Name field. You can either enter the intended name for the document in this field before launching the command, complete with extension (i.e. DocumentName.SchDoc) or leave the name blank and enter the name when saving the generated document at a later stage.

Care should be taken when creating a sheet from a sheet symbol when a sheet with that file name already exists. A new sheet with the same file name will be created. The duplication can be resolved when saving by either saving the new sheet with a different name or overwriting the existing sheet if required.

- Rename Child Sheet - use to quickly rename the child schematic sheet referenced by the sheet symbol. The Rename Child Sheet dialog will open in which you can specify the new name for the document as required, as well as the scope of the renaming action.

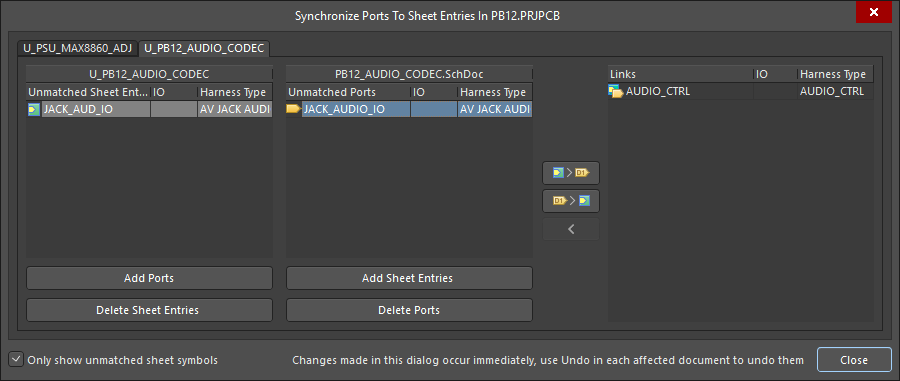

- Synchronize Sheet Entries and Ports - use to synchronize the sheet entries and sub-sheet ports for the sheet symbol. The Synchronize Ports To Sheet Entries dialog will open. Use this dialog to ensure that all sheet entries on the sheet symbol are matched to ports on the referenced child sheet below, both in terms of name and I/O Type.

-

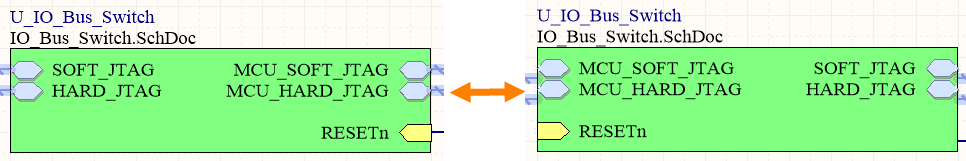

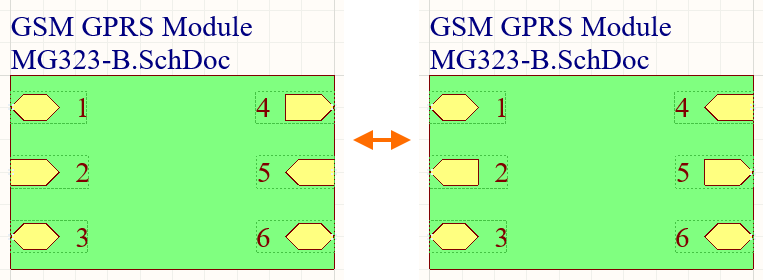

Flip Sheet Symbol Along X - use to flip the sheet symbol along the X-axis. The sheet entries associated with the symbol will essentially be swapped to the opposite side of the symbol (in the horizontal plane). Those on the left will be repositioned on the right and vice-versa.

Example of flipping a sheet symbol along the X-axis

If multiple sheet symbols are currently selected, the command will appear as Flip Selected Sheet Symbols Along X. When flipping multiple selected sheet symbols, the symbols will be flipped along an imaginary vertical line that is located mid-way between the bounding extents of the symbols in the selection.

-

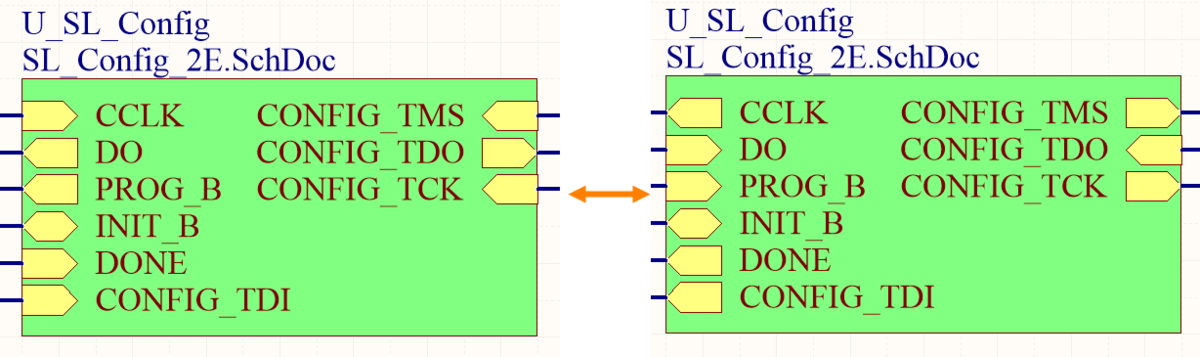

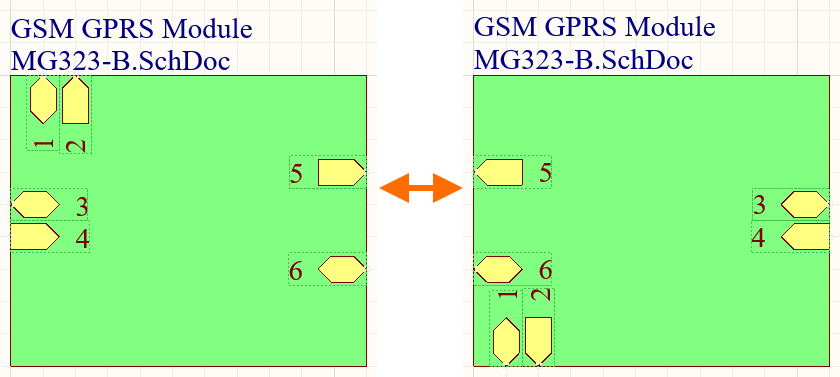

Flip Sheet Symbol Along Y - use to flip the sheet symbol along the Y-axis. The sheet entries associated with the symbol will essentially be swapped to the opposite side of the symbol (in the vertical plane). Those at the top will be repositioned at the bottom and vice-versa.

Example of flipping a sheet symbol along the Y-axis

If multiple sheet symbols are currently selected, the command will appear as Flip Selected Sheet Symbols Along Y. When flipping multiple selected sheet symbols, the symbols will be flipped along an imaginary horizontal line that is located mid-way between the bounding extents of the symbols in the selection.

-

Toggle All Sheet Entries IO Type in Sheet Symbol - use to toggle the I/O Type for all sheet entries in the sheet symbol simultaneously where applicable.

Example result of toggling sheet entry I/O

Example result of toggling sheet entry I/O

The actual change depends on the current PortIO Type as follows:

- Unspecified remains Unspecified.

- Output changes to Input.

- Input changes to Output.

- Bidirectional remains Bidirectional.

Notes

- If a group of sheet entries is pasted into a selected sheet symbol and those entries fall outside the current bounds of the symbol, it will automatically be resized to accommodate them.

-

By using sheet symbol instantiation, multiple channels on the same sub-sheet can be referenced from a single sheet symbol. The syntax used involves the use of the Repeat keyword in the sheet symbol's Designator field and takes the form:

Repeat(SheetSymbolDesignator, FirstInstance, LastInstance), where SheetSymbolDesignator is the base name for the sheet symbol and FirstInstance and LastInstance together define the number of channels to be instantiated.

When the

New Indexing of Sheet Symbols option is enabled on the

Options tab of the Project Options dialog, any digit or number may be used as the first or last index of a repeated Sheet Symbol, including 0; the last index must always be larger than the first index and negative numbers are not allowed.

- Multiple sub-sheets may be referenced by a single sheet symbol. Separate each filename by a semi-colon in the File Name field. With the effective use of off-sheet connectors placed on the sub-sheets, you can spread a section of your design over multiple sheets treating them as though they are one giant (flat) sheet. Note, however, that use of off-sheet connectors is only possible for sheets referenced by the same sheet symbol.

- The

SheetSymbolDesignator special string is available for use. This special string can be placed on a child schematic sheet to display the designator of the associated Sheet Symbol object that is placed on the parent schematic sheet. This special string can also be used in a multi-channel design. Select a compiled tab of the child schematic sheet to display the converted value of the special string.

Sheet Symbol PropertiesExpandCollapse

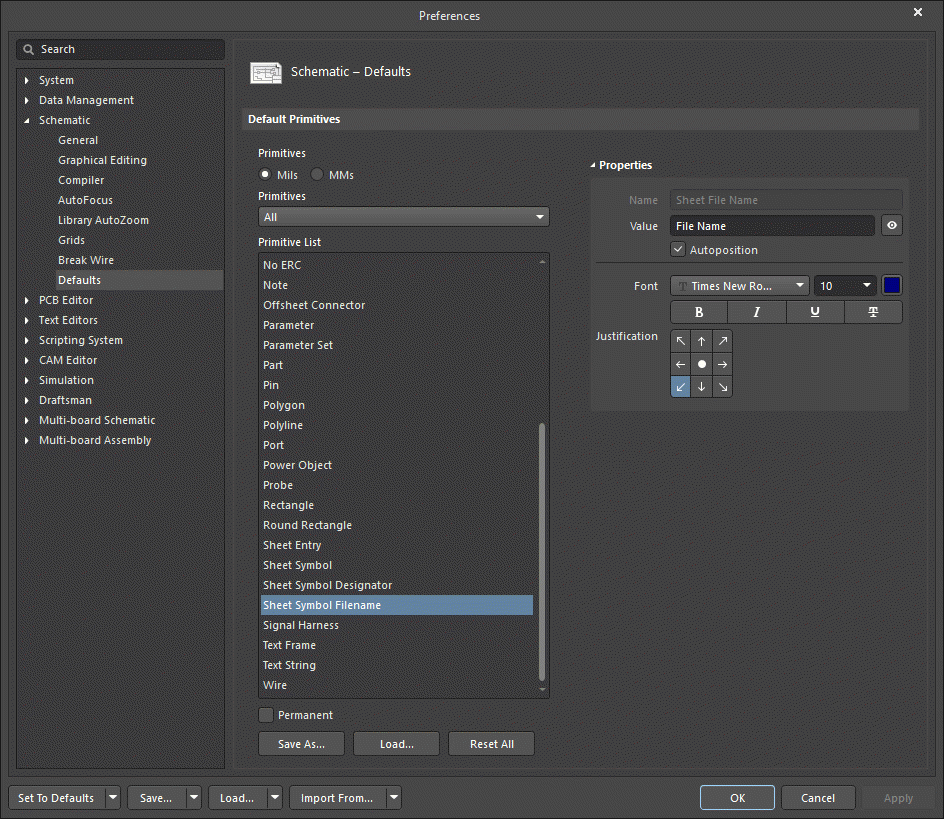

Schematic editor object properties are definable options that specify the visual style, content and behavior of the placed object. The property settings for each type of object are defined in two different ways:

- Pre-placement settings – most Sheet Symbol object properties, or those that can logically be pre-defined, are available as editable default settings on the Schematic - Defaults page of the Preferences dialog (access from the

button at the top-right of the design space). Select the object in the Primitive List to reveal its options on the right.

button at the top-right of the design space). Select the object in the Primitive List to reveal its options on the right.

- Post-placement settings – all Sheet Symbol object properties are available for editing in the Sheet Symbol dialog and the Properties panel when a placed Sheet Symbol is selected in the design space.

If the

Double Click Runs Interactive Properties option is disabled (default) on the

Schematic - Graphical Editing page of the

Preferences dialog, when the primitive is double-clicked or you right-click on a selected primitive then choose

Properties, the dialog will open. When the

Double Click Runs Interactive Properties option is enabled, the

Properties panel will open.

While the options are the same in the dialog and the panel, the order and placement of the options may differ slightly.

In the below properties listing, options that are not available as default settings in the Preferences dialog are noted as "Properties panel only".

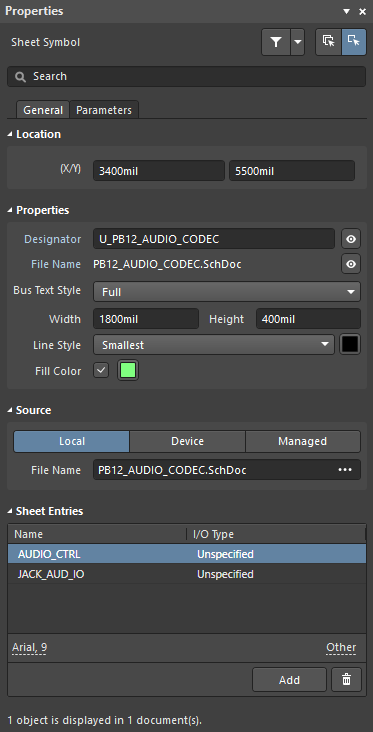

General Tab

Location (Properties panel only)

- (X/Y)

- X (first field) - the current X (horizontal) coordinate of the reference point of the object, relative to the current design space origin. Edit to change the X position of the object. The value can be entered in either metric or imperial; include the units when entering a value whose units are not the current default.

- Y (second field) - The current Y (vertical) coordinate of the reference point of the object, relative to the current origin. Edit to change the Y position of the object. The value can be entered in either metric or imperial; include the units when entering a value whose units are not the current default.

Properties

Source (Properties panel only)

- Local / Device / Managed - the source of the file.

- File Name - displays the current schematic document referenced by the sheet symbol. It is this field that provides the link between the sheet symbol and the schematic sub-sheet that the symbol represents. Click

to open the Choose Document to Reference dialog to choose the required target sub-sheet. The dialog presents a listing of all source schematic sheets in the project (with the exception of the sheet upon which the symbol is currently placed).

to open the Choose Document to Reference dialog to choose the required target sub-sheet. The dialog presents a listing of all source schematic sheets in the project (with the exception of the sheet upon which the symbol is currently placed).

Multiple sub-sheets may be referenced by a single sheet symbol. Separate each file name by a semi-colon in the File Name field. With the effective use of off-sheet connectors placed on the sub-sheets, you can effectively spread a section of your design over multiple sheets, treated as though they were one giant (flat) sheet. Note, however, that use of off-sheet connectors is only possible for sheets referenced by the same sheet symbol.

Sheet Entries (Properties panel only)

- Grid - lists the Name and PortIO Type of all of the sheet entries currently defined for the sheet symbol. When there are sheet entries in the grid, the following additional options are available when an entry is selected:

- Font - click to configure the font style of the sheet entry.

- Other - click to open a drop-down to change additional options:

- Kind - use the drop-down to select the kind of sheet entry.

- Border Color - click to access controls to choose the border color.

- Fill Color - click to access controls to choose the fill color.

- Add - click to add a sheet entry. Use

to delete a selected entry from the table.

to delete a selected entry from the table.

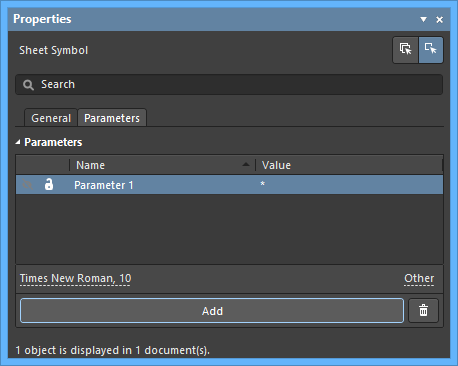

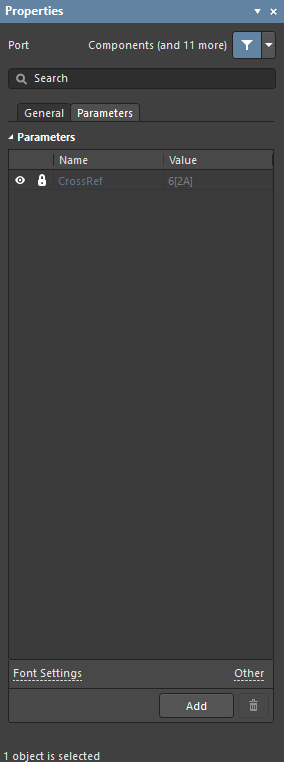

Parameters Tab

Parameters

- Grid - lists the Name and Value of all of the parameters currently defined for the sheet symbol. When there are parameters in the grid, the following additional options are available when a parameter is selected:

- Font - click to configure the font style of the parameter.

- Other - click to open a drop-down to change additional options:

- Show Parameter Name - enable to show the parameter name in the design space.

- Allow Synchronization with Database - enable to synchronize with the database. This option is used to control if the comment can be updated. By default, these options are enabled to always allow synchronization with the source library/database. You may disable this option to prevent that comment from being included in an update process.

- X/Y - enter the X and Y coordinates desired.

- Rotation - use the drop-down to select the rotation.

- Autoposition - check to enable auto-positioning, meaning that the text will remain in the chosen position as the component is moved and rotated.

- Add - click to add a parameter. Use

to delete a selected entry from the table.

to delete a selected entry from the table.

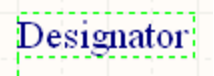

Sheet Symbol DesignatorExpandCollapse

The Sheet Symbol Designator

Summary

The sheet symbol designator is a non-electrical child object of an electrical design primitive. It is used to provide a sheet symbol with a meaningful name that will distinguish it from other sheet symbols placed on the same schematic sheet. Typically the name will reflect the overall function of the schematic sub-sheet that the symbol represents.

Availability and Placement

The sheet symbol designator is automatically placed when the parent component part object is placed. It is not a design object that the user can directly place.

Any changes made to the

Designator field during sheet symbol placement will cause the default properties for the sheet symbol designator object to be updated unless the

Permanent option on the

Schematic - Defaults page of the

Preferences dialog is enabled. When this option is enabled, changes made will affect only the designator of the sheet symbol object being placed and subsequent sheet symbol objects placed during the same placement session.

Graphical Editing

This method of editing allows you to select a sheet symbol designator object directly in the design space and change its location graphically. Sheet symbol designators can only be adjusted with respect to their size by changing the size of the Font in the Properties panel. As such, editing handles are not available when the sheet symbol designator object is selected:

A selected sheet symbol designator

Click anywhere inside the dashed box then drag to reposition the sheet symbol designator object as required. The object can be rotated or flipped while dragging:

- Press the Tab key to access the Properties panel from where properties for the sheet symbol designator can be changed on the fly.

- Press the Alt key to constrain the direction of movement to the horizontal or vertical axis depending on the initial direction of movement.

- Press the Spacebar to rotate the sheet symbol designator counter-clockwise or Shift+Spacebar for clockwise rotation. Rotation is in increments of 90°.

- Press the X or Y keys to mirror the sheet symbol designator along the X-axis or Y-axis.

If the Enable

In-Place Editing option is enabled on the

Schematic - General page of the

Preferences dialog, you will be able to edit the name for the sheet symbol designator directly in the design space. Select the designator then click once to invoke the feature. Type the new name as required then click away from the sheet symbol designator field or press

Enter to effect the change.

If attempting to graphically modify an object that has its Locked property enabled, a dialog will appear asking for confirmation to proceed with the edit. If the Protect Locked Objects option is enabled on the Schematic – Graphical Editing page of the Preferences dialog, and the Locked option for that design object is enabled as well, then that object cannot be selected or graphically edited. Click the locked object to select it then disable the Locked property in the List panel or disable the Protect Locked Objects option to graphically edit the object.

Non-Graphical Editing

The following methods of non-graphical editing are available.

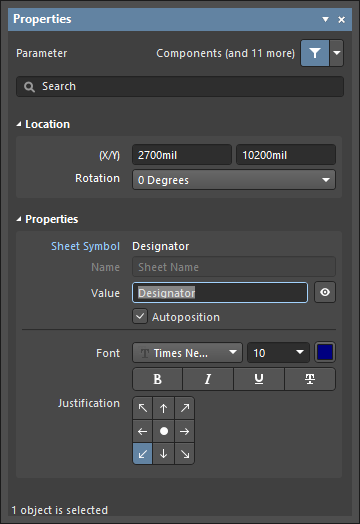

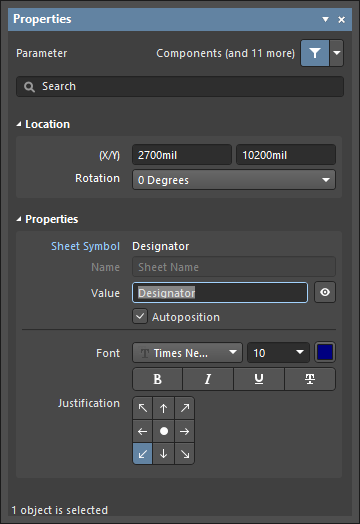

Editing via the Parameter Dialog or Properties Panel

Panel page: Sheet Symbol Designator Properties

This method of editing uses the associated Parameter dialog and the Properties panel mode to modify the properties of a sheet symbol designator object.

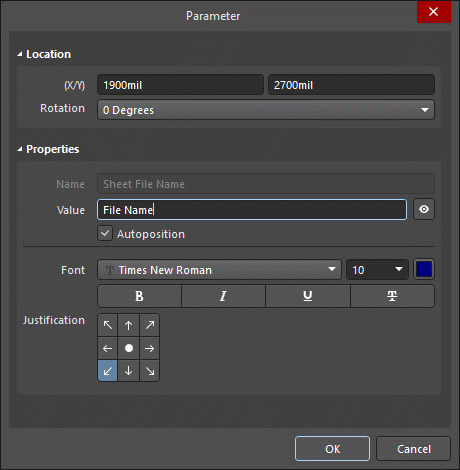

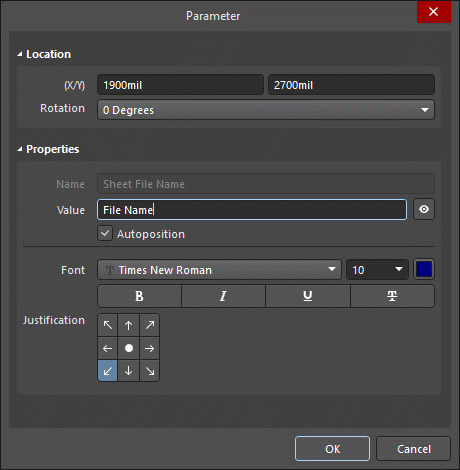

The Parameter dialog, on the left, and the Parameter mode of the Properties panel on the right

The Parameter dialog, on the left, and the Parameter mode of the Properties panel on the right

After placement, the Parameter dialog can be accessed by:

- Double-clicking on the placed sheet symbol designator object.

- Placing the cursor over the sheet symbol designator object, right-clicking then choosing Properties from the context menu.

During placement, the Parameter mode of the Properties panel can be accessed by pressing the Tab key. Once the sheet symbol designator is placed, all options appear.

After placement, the Parameter mode of the Properties panel can be accessed in one of the following ways:

- If the Properties panel is already active, by selecting the sheet symbol designator object.

- After selecting the sheet symbol designator object, select the Properties panel from the Panels button at the bottom right of the design space or select View » Panels » Properties.

If the

Double Click Runs Interactive Properties option is disabled (default) on the

Schematic - Graphical Editing page of the

Preferences dialog, when the primitive is double-clicked or you right-click on a selected primitive then choose

Properties, the dialog will open. When the

Double Click Runs Interactive Properties option is enabled, the

Properties panel will open.

While the options are the same in the dialog and the panel, the order and placement of the options may differ slightly.

The sheet symbol designator properties can be accessed prior to entering placement mode from the

Schematic – Defaults page of the

Preferences dialog. This allows the default properties for the sheet symbol designator object to be changed, which will be applied when placing subsequent sheet symbol designators.

Editing Multiple Objects

The Properties panel supports multiple object editing, where the property settings that are identical in all currently selected objects may be modified. When multiples of the same object type are selected manually, via the Find Similar Objects dialog or through a Filter or List panel, a Properties panel field entry that is not shown as an asterisk (*) may be edited for all selected objects.

Editing via a List Panel

Panel pages: SCH List, SCHLIB List, SCH Filter, SCHLIB Filter

A List panel allows you to display design objects from one or more documents in tabular format, enabling quick inspection and modification of object attributes. Used in conjunction with appropriate filtering - by using the applicable Filter panel, or the Find Similar Objects dialog - it enables the display of just those objects falling under the scope of the active filter – allowing you to target and edit multiple design objects with greater accuracy and efficiency.

Notes

- While text frames can be rotated or mirrored along the X or Y axis, this has no effect on the orientation of the text within.

- For simple one-line text annotations, consider using the Text String object.

-

By using sheet symbol instantiation, multiple channels on the same sub-sheet can be referenced from a single sheet symbol. The syntax used involves the use of the Repeat keyword in the sheet symbol designator field and takes the form:

Repeat(SheetSymbolDesignator, FirstInstance, LastInstance).

Using Repeat keyword

SheetSymbolDesignator is the base name for the sheet symbol and FirstInstance and LastInstance together define the number of channels to be instantiated. When the project is built, the Compiler instantiates the channel the required number of times as it builds the internal compiled model, using a chosen annotation scheme to uniquely identify each component in each channel. The channel sub-sheet is not duplicated. Instead, once compiled, a separate tab appears at the bottom of the sub-sheet document in the main design window for each channel on that sheet.

When the

New Indexing of Sheet Symbols option is enabled on the

Options tab of the Project Options dialog, any digit or number may be used as the first or last index of a repeated Sheet Symbol, including 0; the last index must always be larger than the first index and negative numbers are not allowed.

- The

SheetSymbolDesignator special string is available for use. This special string can be placed on a child schematic sheet to display the designator of the associated Sheet Symbol object that is placed on the parent schematic sheet. This special string can also be used in a multi-channel design. Select a compiled tab of the child schematic sheet to display the converted value of the special string.

Sheet Symbol Designator PropertiesExpandCollapse

Schematic editor object properties are definable options that specify the visual style, content and behavior of the placed object. The property settings for each type of object are defined in two different ways:

-

Pre-placement settings – most Sheet Symbol Designator object properties, or those that can logically be pre-defined, are available as editable default settings on the Schematic - Defaults page of the Preferences dialog (access from the  button at the top-right of the design space). Select the object in the Primitive List to reveal its options on the right.

button at the top-right of the design space). Select the object in the Primitive List to reveal its options on the right.

-

Post-placement settings – all Sheet Symbol Designator object properties are available for editing in the Parameter dialog and the Properties panel when a placed Sheet Symbol Designator is selected in the design space.

If the

Double Click Runs Interactive Properties option is disabled (default) on the

Schematic - Graphical Editing page of the

Preferences dialog, when the primitive is double-clicked or you right-click on a selected primitive then choose

Properties, the dialog will open. When the

Double Click Runs Interactive Properties option is enabled, the

Properties panel will open.

While the options are the same in the dialog and the panel, the order and placement of the options may differ slightly.

In the below properties listing, options that are not available as default settings in the Preferences dialog are noted as "Properties panel only".

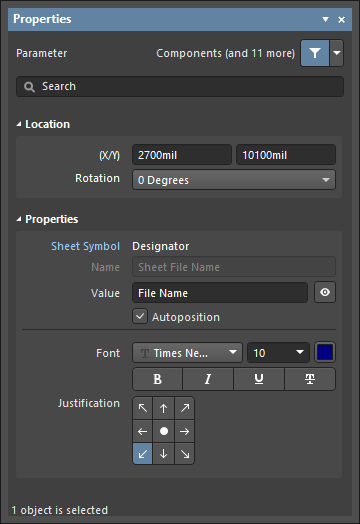

Location (Properties panel only)

- (X/Y)

- X (first field) - the current X (horizontal) coordinate of the reference point of the object, relative to the current design space origin. Edit to change the X position of the object. The value can be entered in either metric or imperial; include the units when entering a value whose units are not the current default.

- Y (second field) - The current Y (vertical) coordinate of the reference point of the object, relative to the current origin. Edit to change the Y position of the object. The value can be entered in either metric or imperial; include the units when entering a value whose units are not the current default.

- Rotation - use the drop-down to select the rotation.

Properties

Sheet Symbol File NameExpandCollapse

Sheet Symbol File Name

Summary

The Sheet Symbol File Name is a non-electrical child object of an electrical design primitive. It provides the link between the sheet symbol and the schematic sub-sheet that the symbol represents.

Availability and Placement

The Sheet Symbol File Name is automatically placed when the parent sheet symbol object is placed.

While attributes can be modified during placement (

Tab to access the

Properties panel), keep in mind that these will become the default settings for further placement unless the

Permanent option on the

Schematic – Defaults page of the

Preferences dialog is enabled. When this option is enabled, changes made will affect only the object being placed and subsequent objects placed during the same placement session.

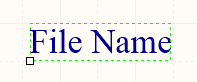

Graphical Editing

This method of editing allows you to select a sheet symbol file Name object directly in the design space and change its location graphically. Sheet symbol file Names can only be adjusted with respect to their size by changing the size of the Font in the Properties panel. As such, editing handles are not available when the sheet symbol file name object is selected.

Click anywhere inside the dashed box and drag to reposition the sheet symbol filename object as required. The object can be rotated or flipped while dragging.

Click anywhere inside the dashed box and drag to reposition the sheet symbol filename object as required. The object can be rotated or flipped while dragging.

Press the Spacebar to rotate the file name. Rotation is counterclockwise in increments of 90°.

If the Enable

In-Place Editing option is enabled on the

Schematic - General page of the

Preferences dialog, you will be able to edit the name for the sheet symbol file name directly in the design space. Select the designator then click once to invoke the feature. Type the new name as required then click away from the sheet symbol file name or press

Enter to effect the change.

If attempting to graphically modify an object that has its Locked property enabled, a dialog will appear asking for confirmation to proceed with the edit. If the Protect Locked Objects option is enabled on the Schematic – Graphical Editing page of the Preferences dialog, and the Locked option for that design object is enabled as well, then that object cannot be selected or graphically edited. Click the locked object to select it then disable the Locked property in the List panel or disable the Protect Locked Objects option to graphically edit the object.

Non-Graphical Editing

The following methods of non-graphical editing are available.

Editing via the Parameter Dialog or Properties Panel

Panel page: Sheet Symbol File Name Properties

This method of editing uses the associated Parameter dialog and the Properties panel mode to modify the properties of a sheet symbol file name object.

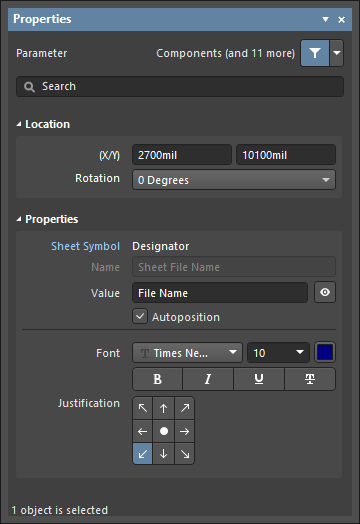

The Parameter dialog, on the left, and the Parameter mode of the Properties panel on the right

The Parameter dialog, on the left, and the Parameter mode of the Properties panel on the right

After placement, the Parameter dialog can be accessed by:

- Double-clicking on the placed sheet symbol object.

- Place the cursor over the sheet symbol object, right-click, then choose Properties from the context menu.

During placement, the Parameter mode of the Properties panel can be accessed by pressing the Tab key. Once the sheet symbol is placed, all options appear.

After placement, the Parameter mode of the Properties panel can be accessed in one of the following ways:

- If the Properties panel is already active, by selecting the Sheet Symbol object.

- After selecting the sheet symbol object, select the Properties panel from the Panels button at the bottom right of the design space or select View » Panels » Properties.

If the

Double Click Runs Interactive Properties option is disabled (default) on the

Schematic - Graphical Editing page of the

Preferences dialog, when the primitive is double-clicked or you right-click on a selected primitive then choose

Properties, the dialog will open. When the

Double Click Runs Interactive Properties option is enabled, the

Properties panel will open.

While the options are the same in the dialog and the panel, the order and placement of the options may differ slightly.

The sheet symbol file name properties can be accessed prior to entering placement mode from the

Schematic – Defaults page of the

Preferences dialog. This allows the default properties for the sheet symbol file name object to be changed, which will be applied when placing subsequent sheet symbol file names.

Editing Multiple Objects

The Properties panel supports multiple object editing, where the property settings that are identical in all currently selected objects may be modified. When multiples of the same object type are selected manually, via the Find Similar Objects dialog or through a Filter or List panel, a Properties panel field entry that is not shown as an asterisk (*) may be edited for all selected objects.

Editing via a List Panel

Panel pages: SCH List, SCHLIB List, SCH Filter, SCHLIB Filter

A List panel allows you to display design objects from one or more documents in tabular format, enabling quick inspection and modification of object attributes. Used in conjunction with appropriate filtering - by using the applicable Filter panel, or the Find Similar Objects dialog - it enables the display of just those objects falling under the scope of the active filter – allowing you to target and edit multiple design objects with greater accuracy and efficiency.

Sheet Symbol Filename PropertiesExpandCollapse

Schematic Editor object properties are definable options that specify the visual style, content and behavior of the placed object. The property settings for each type of object are defined in two different ways:

- Pre-placement settings – most Sheet Symbol Filename object properties, or those that can logically be pre-defined, are available as editable default settings on the Schematic - Defaults page of the Preferences dialog (access from the

button at the top-right of the design space). Select the object in the Primitive List to reveal its options on the right.

button at the top-right of the design space). Select the object in the Primitive List to reveal its options on the right.

- Post-placement settings – all Sheet Symbol Filename object properties are available for editing in the Parameter dialog and the Properties panel when a placed Sheet Symbol Filename is selected in the design space.

If the

Double Click Runs Interactive Properties option is disabled (default) on the

Schematic - Graphical Editing page of the

Preferences dialog, when the primitive is double-clicked or you right-click on a selected primitive then choose

Properties, the dialog will open. When the

Double Click Runs Interactive Properties option is enabled, the

Properties panel will open.

While the options are the same in the dialog and the panel, the order and placement of the options may differ slightly.

In the below properties listing, options that are not available as default settings in the Preferences dialog are noted as "Properties panel only".

Location (Properties panel only)

- Search - use this field to search for the desired text within the Properties panel. Once found, the text searched will be highlighted.

- (X/Y)

- X (first field) - the current X (horizontal) coordinate of the reference point of the object, relative to the current design space origin. Edit to change the X position of the object. The value can be entered in either metric or imperial; include the units when entering a value whose units are not the current default.

- Y (second field) - The current Y (vertical) coordinate of the reference point of the object, relative to the current origin. Edit to change the Y position of the object. The value can be entered in either metric or imperial; include the units when entering a value whose units are not the current default.

- Rotation - use the drop-down to select the rotation.

Properties

- Sheet Symbol - the sheet symbol associated with this object.

- Name - displays the name.

- Value - displays the actual filename text. Use

/

/  to determine whether the Value for the object is displayed or hidden. Check Autoposition to enable auto-positioning.

to determine whether the Value for the object is displayed or hidden. Check Autoposition to enable auto-positioning.

- Font - use the controls to configure the font, font size, color, and special settings such as bold and underlining.

- Justification - select the desired justification of the text.

Hierarchical Design

It is important to remember that for hierarchical designs, a project can contain only one top sheet. All other source documents must be referenced by sheet symbols. When performing a design validation, the

Multiple Top Level Documents violation check can be used to flag if this is not the case. In addition, no sheet symbol may reference the sheet it's on or any sheet higher up the ladder, as this will create an irresolvable loop in the structure.

A hierarchical design is one that has Sheet Symbols to create the parent-child type relationships between the sheets, and, the connectivity is through the Sheet Entries in those Sheet Symbols - not directly from the Ports on one sheet to the Ports on another sheet.

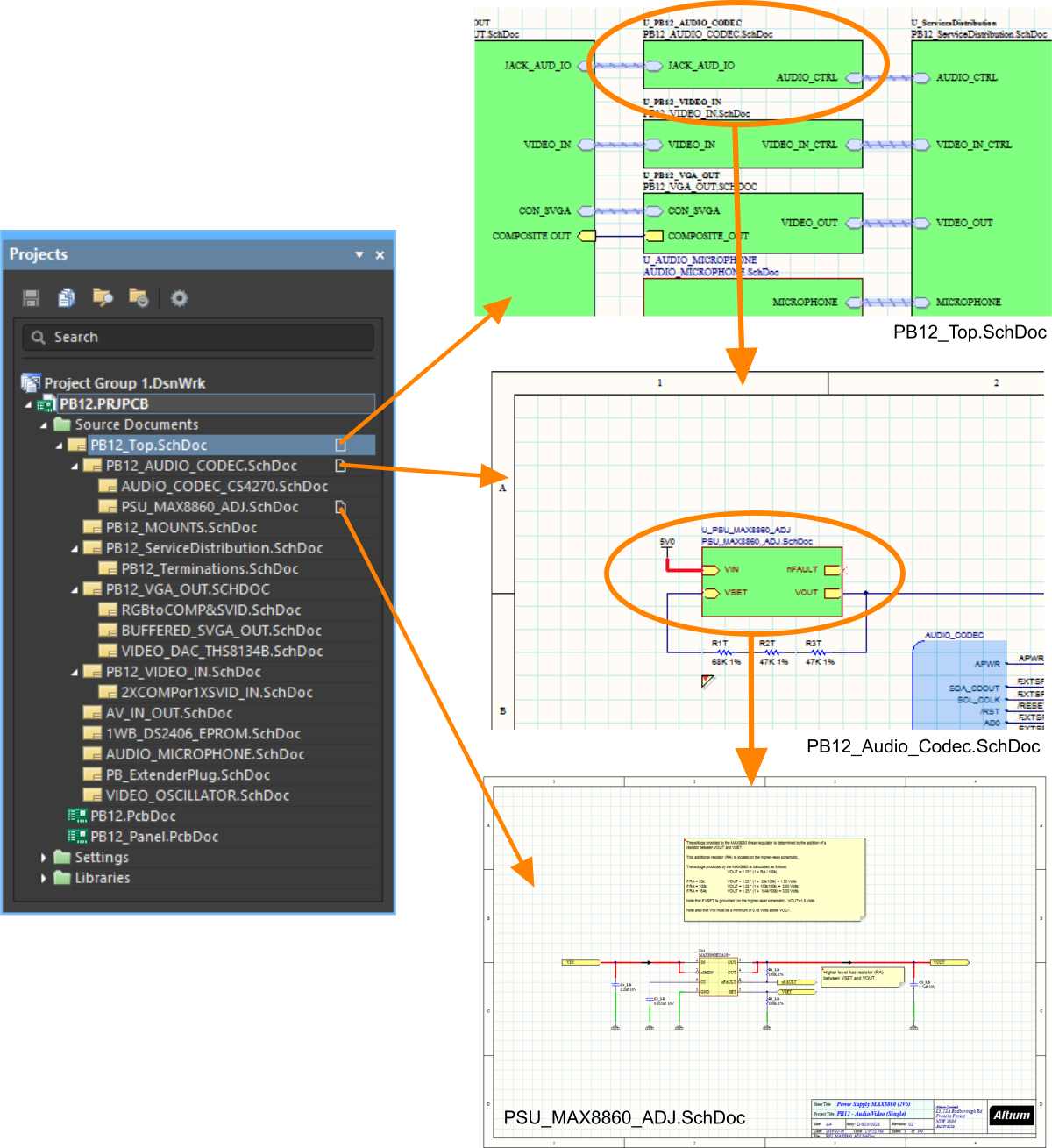

As in a flat design, the child sheet is identified by defining its filename in the sheet symbol. In a hierarchical design, that child sheet can also include sheet symbols, referencing lower-level sheets, thus creating another level in the hierarchy. The image below shows a hierarchical design, with 3 levels in the hierarchy.

In a hierarchical design, the structure shown in the tree is determined by the parent-to-child relationships created by the sheet symbols.

In a hierarchical design, a signal on a child sheet leaves the sheet via a Port, which connects upward to a matching Sheet Entry on the parent sheet. The parent sheet includes wiring that carries the child signal across to a Sheet Entry in another Sheet Symbol, it then travels down to a matching Port on the second child sheet, as shown in the image below.

This parent-child sheet structure can be defined to any depth, and there can be any number of sheets in a hierarchical design.

The connectivity between the sheets is determined by the Net Identifier Scope. This is set in the Options tab of the Options for Project dialog. To learn more about creating connectivity, read the Creating Connectivity article. Note that the Net Identifier Scope includes an Automatic option, unless you have unusual connectivity requirements, this option is a good choice.

Another advantage of a hierarchical design is that it provides the platform for the delivery of a sophisticated design reuse system. This system is delivered in two ways, depending on how the data is stored, either: file-based or server-based.

- The file-based system is called Device Sheets, where you place an existing schematic from a library of Device Sheets directly into the design being created. To learn more about Device Sheets, refer to the Device Sheets article.

- The server-based system is called Managed Sheets, where you place an existing schematic from a managed content server directly into the design being created. To learn more about Managed Sheets, refer to the Managed Sheets article.

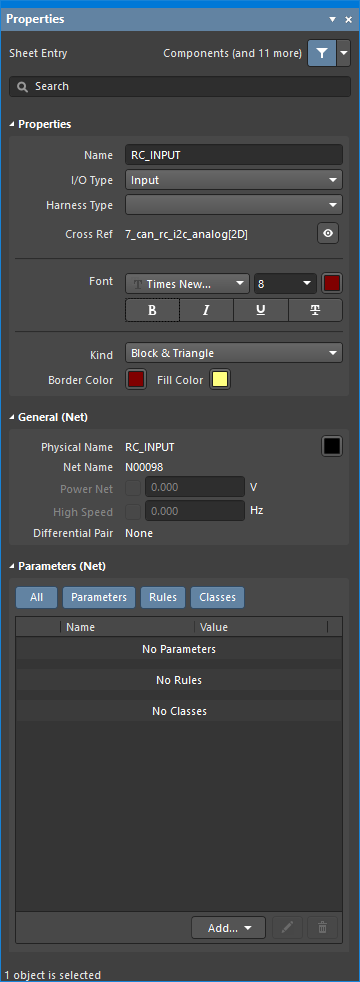

PortExpandCollapse

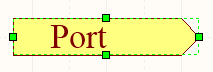

A placed Port

A placed Port

Summary

A port is an electrical design primitive. It is used to make an electrical connection between one schematic sheet and another sheet, or sheet symbol (through a corresponding sheet entry) in a design using multiple sheets (both flat and hierarchical designs). The name of the port defines the connection (i.e. a port on a schematic sheet connects to ports or sheet entries with the same name on other sheets in the project).

Note that the

Cross Reference feature identifies the locations of interconnected

Ports and positional grid references for interconnected off sheet connectors. For both types of schematic connection objects, the existing

Reports » Port Cross Reference » Add To Project command adds a cross-reference parameter based on the target sheet name and a positional grid reference.

Availability

Ports are available for placement in the Schematic Editor in the following ways:

- Click Place » Port from the main menus.

- Click the Port button (

) in the directives drop-down on the Active Bar, located at the top of the design space. (Click and hold an Active Bar button to access other related commands. Once a command has been used, it will become the topmost item on that section of the Active Bar.)

) in the directives drop-down on the Active Bar, located at the top of the design space. (Click and hold an Active Bar button to access other related commands. Once a command has been used, it will become the topmost item on that section of the Active Bar.)

- Right-click then select Place » Port.

Placement

After launching the command, the cursor will change to a cross-hair and you will enter port placement mode. Placement is made by performing the following sequence of actions:

- Click or press Enter to anchor the left-hand edge of the port.

- Move the cursor to adjust the length of the port as required then click or press Enter to complete placement of the port.

- Continue placing further ports or right-click or press Esc to exit placement mode.

Additional actions that can be performed during placement while the port is still floating on the cursor and before its left-hand edge is anchored are:

- Press the Tab key to pause the placement and access the Port mode of the Properties panel in which its properties can be changed on the fly. Click the design space pause button overlay (

) to resume placement.

) to resume placement.

- Press the Spacebar to rotate the port counterclockwise or Shift+Spacebar for clockwise rotation. Rotation is in increments of 90°.

- Press the X or Y keys to mirror the port along the X-axis or Y-axis.

While attributes can be modified during placement (Tab to access the associated Properties panel), keep in mind that these will become the default settings for further placement unless the Permanent option on the Schematic – Defaults page of the Preferences dialog is enabled. When this option is enabled, changes made will affect only the object being placed and subsequent objects placed during the same placement session.

Graphical Editing

This method of editing allows you to select a placed port object in the design space and graphically change its length, height, or location.

When a port object is selected, you can click and drag the editing handles to resize the port.

A selected Port

A selected Port

Click anywhere on the port away from editing handles then drag to reposition it. While dragging, the port can be rotated (Spacebar/Shift+Spacebar) or mirrored (X or Y keys to mirror along the X-axis or Y-axis).

The name for the port object can be edited in-place by:

- Single-click the port to select it.

- Single-click again (or pressing Enter) to enter the in-place editing mode. Sufficient time between each click should be given to ensure the software does not interpret the two single-clicks as one double-click (which would open the Properties panel).

- To finish editing in-place text, press Enter or use the mouse to click away from the port.

If attempting to graphically modify an object that has its Locked property enabled, a dialog will appear asking for confirmation to proceed with the edit. If the Protect Locked Objects option is enabled on the Schematic – Graphical Editing page of the Preferences dialog, and the Locked option for that design object is enabled as well, then that object cannot be selected or graphically edited. Click the locked object to select it then disable the Locked property in the List panel or disable the Protect Locked Objects option to graphically edit the object.

Non-Graphical Editing

The following methods of non-graphical editing are available.

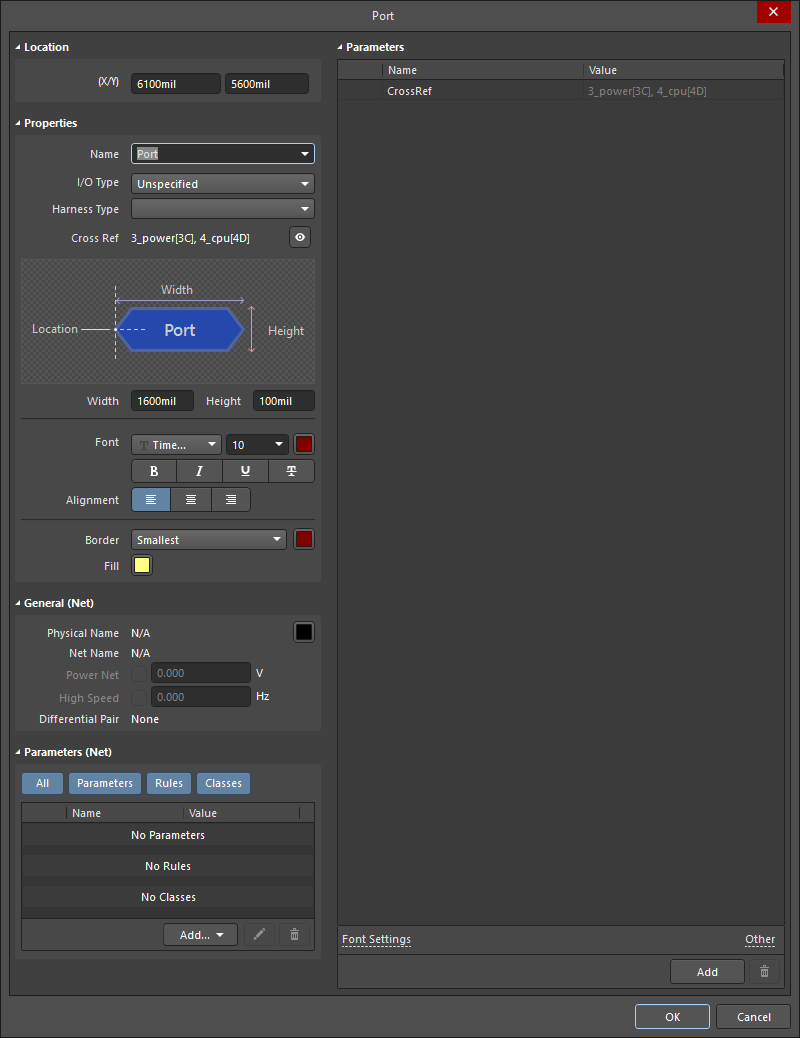

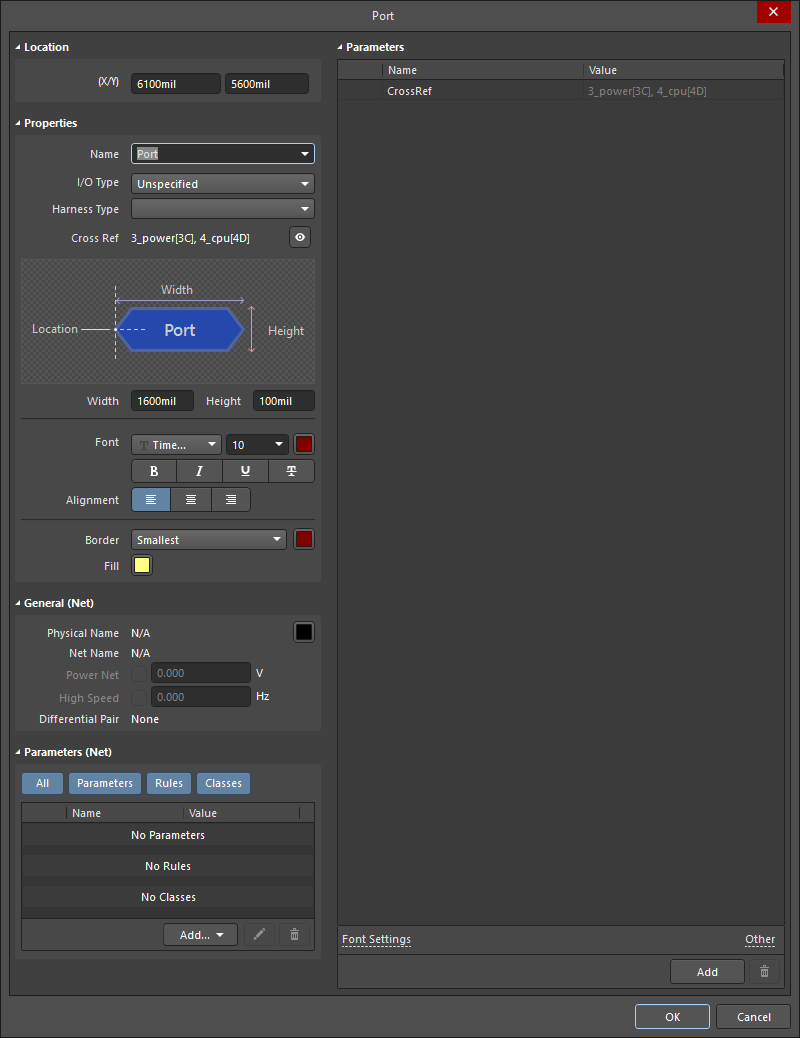

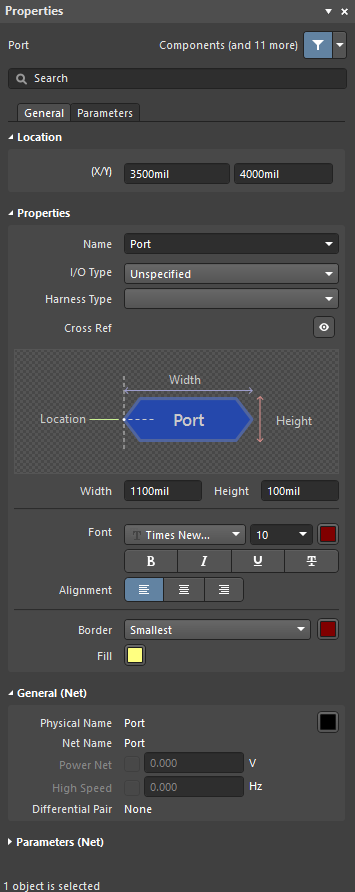

Editing via the Port Dialog or Properties Panel

Properties page: Port Properties

This method of editing uses the associated Port dialog and the Properties panel mode to modify the properties of a port object.

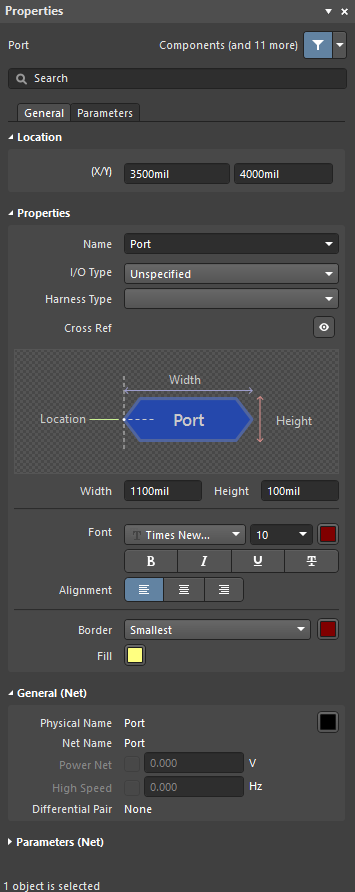

The Port dialog, on the left, and the Port mode of the Properties panel on the right

The Port dialog, on the left, and the Port mode of the Properties panel on the right

After placement, the Port dialog can be accessed by:

- Double-clicking on the placed port object.

- Placing the cursor over the port object, right-clicking, then choosing Properties from the context menu.

During placement, the Port mode of the Properties panel can be accessed by pressing the Tab key. Once the port is placed, all options appear.

After placement, the Port mode of the Properties panel can be accessed in one of the following ways:

- If the Properties panel is already active, by selecting the port object.

- After selecting the port object, select the Properties panel from the Panels button at the bottom right of the design space or select View » Panels » Properties from the main menu.

If the

Double Click Runs Interactive Properties option is disabled (default) on the

Schematic - Graphical Editing page of the

Preferences dialog, when the primitive is double-clicked or you right-click on a selected primitive then choose

Properties, the dialog will open. When the

Double Click Runs Interactive Properties option is enabled, the

Properties panel will open.

While the options are the same in the dialog and the panel, the order and placement of the options may differ slightly.

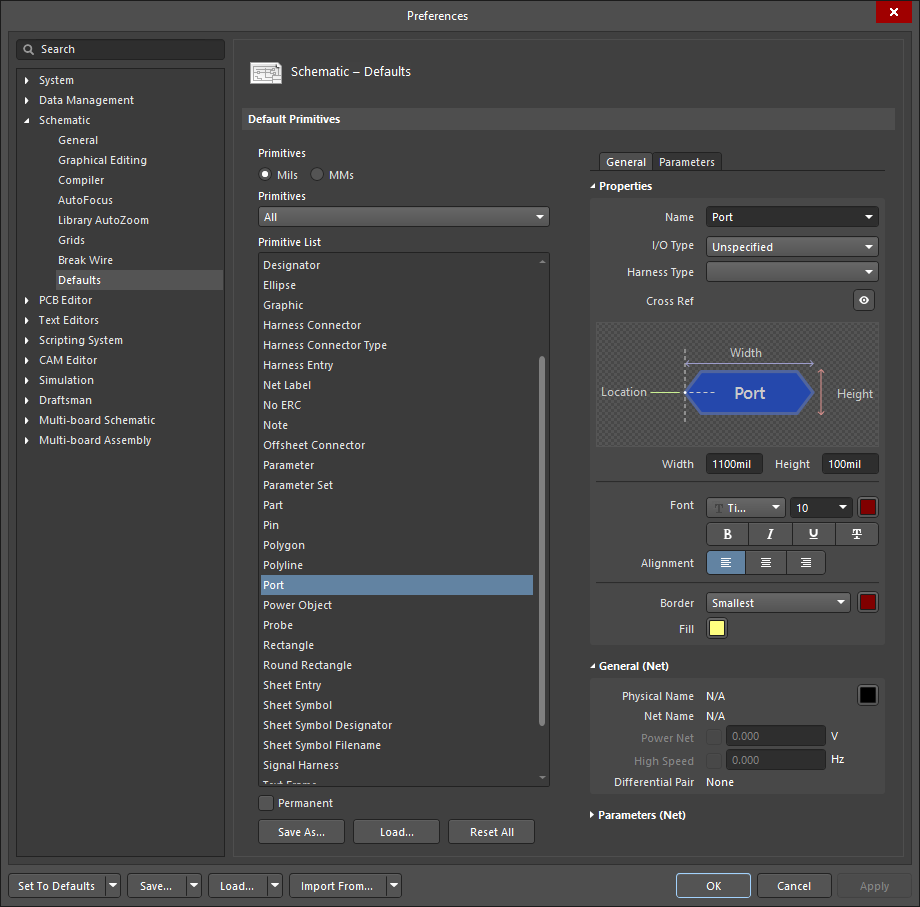

The Port properties can be accessed prior to entering placement mode from the

Schematic – Defaults page of the

Preferences dialog. This allows the default properties for the port object to be changed, which will be applied when placing subsequent ports.

Editing Multiple Objects

The Properties panel supports multiple object editing, where the property settings that are identical in all currently selected objects may be modified. When multiples of the same object type are selected manually, via the Find Similar Objects dialog or through a SCH Filter or SCH List panel, a Properties panel field entry that is not shown as an asterisk (*) may be edited for all selected objects.

Editing via a List Panel

Panel pages: SCH List, SCH Filter

A List panel allows you to display design objects from one or more documents in tabular format, enabling quick inspection and modification of object attributes. Used in conjunction with appropriate filtering - by using the applicable Filter panel or the Find Similar Objects dialog - it enables the display of just those objects falling under the scope of the active filter – allowing you to target and edit multiple design objects with greater accuracy and efficiency.

Port Actions

Right-click over a placed port to pop-up a context-sensitive menu, from which the following commands are available (on the Port Actions sub-menu) that act on that port (or all currently selected ports, where applicable):

- Jump to Sheet Entry <PortName> - use to jump to the port's corresponding sheet entry in the parent sheet symbol that references the sub-sheet on which the port resides.

- Toggle Port IO Type - use to toggle the I/O Type for the port.

The actual change depends on the current I/O Type as follows:

- Unspecified remains Unspecified.

- Output changes to Input.

- Input changes to Output.

- Bidirectional remains Bidirectional.

If multiple ports are currently selected, the command will appear as Toggle Selected Ports IO Type. The command will apply to all selected ports.

- Place Harness Connector of Type <HarnessConnectorType> - use to place a harness connector (complete with respective defined harness entries) for connection to the port.

This command is only available for a port that has a defined Harness Type.

- Jump to Port <PortName> on <SheetName> - use to jump to another port with the same name on the indicated source schematic document.

Notes

- When compiling a schematic or generating a netlist, the relationship between ports and sheet symbols is determined by the Net Identifier Scope chosen for the project. This scope is defined by setting the Net Identifier Scope option on the Project Options - Options dialog (Project » Project Options). When set to Flat or Global, all ports with the same name within the same or different schematic documents are considered to be electrically connected. When set to Hierarchical or Strict Hierarchical, ports only connect vertically to their corresponding sheet entries. They do not connect horizontally to other ports of the same name.

- The I/O Type option in the Properties panel allows you to define the port's electrical type. Choose from either

Input, Output, Bidirectional,or Unspecified.

- Should you need to negate (include a bar over the top of) a port name, include a backslash character after each character in the name (e.g.,

E\N\A\B\L\E\).

- Port names are not used for naming nets. This means a system-generated net name will be used if no net label or power object is associated with that net.

- When a Port is connected to a Signal Harness, the Port becomes a Harness object. By default, the Port will change color to match the color of the Signal Harness.

- When a Port is connected to a Harness Connector by a Signal Harness, the Harness Type in the Properties panel is automatically populated with the Harness Type of the Harness Connector. When a Port is connected to a Sheet Entry by a Signal Harness and the Sheet Entry has a Harness Type declared, the Port will become a Harness object and change to the color of the Signal Harness. If you move the Port away from the Harness Connector or the Sheet Entry, the Port will revert back to the default color.

- By default, the font used for the port's Name follows the global document-level font set in the Document Font options in the Document Options mode of the Properties panel (when no objects are selected in the workspace). This can be overridden at the individual port-level with the Font settings in the Properties panel allowing you to fully control the textual presentation of ports as needed.

Port PropertiesExpandCollapse

Schematic Editor object properties are definable options that specify the visual style, content and behavior of the placed object. The property settings for each type of object are defined in two different ways:

- Pre-placement settings – most Port object properties, or those that can logically be pre-defined, are available as editable default settings on the Schematic - Defaults page of the Preferences dialog (accessed from the

button at the top-right of the design space). Select the object in the Primitive List to reveal its options on the right.

button at the top-right of the design space). Select the object in the Primitive List to reveal its options on the right.

- Post-placement settings – all Port object properties are available for editing in the Port dialog and the Properties panel when a placed Port is selected in the design space.

If the

Double Click Runs Interactive Properties option is disabled (default) on the

Schematic - Graphical Editing page of the

Preferences dialog, when the primitive is double-clicked or you right-click on a selected primitive then choose

Properties, the dialog will open. When the

Double Click Runs Interactive Properties option is enabled, the

Properties panel will open.

While the options are the same in the dialog and the panel, the order and placement of the options may differ slightly.

In the below properties listing, options that are not available as default settings in the Preferences dialog are noted as "Properties panel only".

General Tab

Location (Properties panel only)

- (X/Y)

- X (first field) - the current X (horizontal) coordinate of the reference point of the object, relative to the current design space origin. Edit to change the X position of the object. The value can be entered in either metric or imperial; include the units when entering a value whose units are not the current default.

- Y (second field) - The current Y (vertical) coordinate of the reference point of the object, relative to the current origin. Edit to change the Y position of the object. The value can be entered in either metric or imperial; include the units when entering a value whose units are not the current default.

Properties

- Name - the name of the port.

- I/O Type - defines the electrical properties of the port. Select an option from the drop-down list.

This setting does not influence the connectivity of the circuit, however, it is considered during the running of an electrical rules check, which can be set to detect incompatible port directions.

- Harness Type - use the drop-down to select the type of harness.

- Cross Ref - this field displays cross-reference values that are applied to the port.

The cross-reference capabilities are available when the

Schematic.UseAutomaticCrossReferences option is enabled in the

Advanced Settings dialog.

- Width - can be edited.

- Height - can be edited.

- Font - use the controls to select the desired font, font size, color, and attributes to bold, italicize, etc., if desired.

- Alignment - click the desired alignment setting.

- Border - use the drop-down to select the default from the available choices. Click on the colored box to access a drop-down from which you can select the default color.

- Fill - click on the color box to access a drop-down from which you can select the default color.

General (Net)

Displays the properties of the nets assigned to the port. Update as needed.

The Power Net and High Speed fields become available after a directive has been added to the object.

Parameters (Net)

- Selection buttons - click the desired objects to display in the grid.

- Add - use the drop-down to add the desired object(s) then define the values.

The Add button becomes available after a directive has been added to the object.

Parameters Tab

Parameters

Use this region to manage parameters attached to the currently selected port object.

- Grid - lists the Name and Value of the parameters currently defined for the port. You can edit the fields directly if desired. Use

and

and  to show/hide the parameter. Use the lock icon to lock/unlock the selected parameter.

to show/hide the parameter. Use the lock icon to lock/unlock the selected parameter.

- Font Settings - click to open a menu to define the font.

- Other - click to open a drop-down to change additional options:

- Show Parameter Name - enable to show the name of the parameter.

- Allow Synchronization with Database - enable to synchronize with the database.

- X/Y - enter the X and Y coordinates.

- Rotation - use the drop-down to select the rotation.

- Autoposition - check to enable auto-positioning.

- Add - click to add a parameter. Use

to delete a selected entry from the table.

to delete a selected entry from the table.

Note that the

Cross Reference feature identifies the locations of interconnected

Ports and positional grid references for interconnected off sheet connectors. For both types of schematic connection objects, the existing

Reports » Port Cross Reference » Add To Project command adds a cross-reference parameter based on the target sheet name and a positional grid reference.

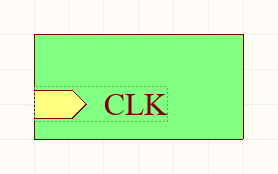

Sheet EntryExpandCollapse

A placed Sheet Entry

Summary

A sheet entry is an electrical design primitive that belongs within a sheet symbol. It is placed within a sheet symbol to designate input/output ports for the symbol. The sheet entries correspond to ports placed in the source schematic sub-sheet that the symbol represents.

Availability

Sheet Entries are available for placement in the Schematic Editor only in the following ways:

- Choose Place » Sheet Entry from the main menus.

- Click the Sheet Entry button (

) in the graphic objects drop-down on the Active Bar located at the top of the design space. (Click and hold an Active Bar button to access other related commands. Once a command has been used, it will become the top-most item on that section of the Active Bar.)

) in the graphic objects drop-down on the Active Bar located at the top of the design space. (Click and hold an Active Bar button to access other related commands. Once a command has been used, it will become the top-most item on that section of the Active Bar.)

- Right-click in the design space then choose Place » Sheet Entry from the context menu.

- Click the

button on the Wiring toolbar.

button on the Wiring toolbar.

Placement

After launching the command, the cursor will change to a cross-hair and you will enter sheet entry placement mode. Placement is made by performing the following sequence of actions:

- Move the sheet entry attached to the cursor over a placed sheet symbol on the sheet.

- Adjust the position of the sheet entry in relation to an edge of the sheet symbol, then click or press Enter to anchor the sheet entry to the required edge and complete placement.

- Continue placing further sheet entries or right-click or press Esc to exit placement mode.

The coloring of the sheet entry will aid in its correct placement. While outside of a sheet symbol, the entry will appear grayed-out and you will be prevented from placing it. When over a sheet symbol, the entry will turn blue indicating it can be placed at that location. Once placed, the entry will revert to its true coloring as defined by its

Fill Color property in the

Properties panel.

While attributes can be modified during placement (

Tab to access the

Properties panel), keep in mind that these will become the default settings for further placement unless the

Permanent option on the

Schematic – Defaults page of the

Preferences dialog is enabled. When this option is enabled, changes made will affect only the object being placed and subsequent objects placed during the same placement session.

Graphical Editing

This method of editing allows you to select a placed sheet entry object directly in the design space and change its location graphically.

Sheet entries can only be adjusted with respect to their shape by changing their I/O Type in the Properties panel. As such, editing handles are not available when the Sheet Entry object is selected.

A selected Sheet Entry

- Click and drag to reposition the sheet entry within its parent sheet symbol as required.

- Hold Ctrl then click and drag the sheet entry to move it from the current sheet symbol to another sheet symbol on the sheet. Once the sheet entry has cleared the boundary of the source sheet symbol, the Ctrl key can be released.

- Clicking and dragging the sheet entry outside of the sheet symbol boundary will cause the sheet symbol to automatically resize to accommodate the entry's new location.

Multiple sheet entries can be moved simultaneously by selecting all entries to be moved by holding Ctrl and clicking on one entry in the selection, then dragging the entire selection. Once you begin the drag, the Ctrl key can be released. Select multiple objects by holding Shift.

If the

Enable In-Place Editing option is enabled on the

Schematic – General page of the

Preferences dialog, you can edit the name for the sheet entry directly in the design space. Select the sheet entry object then click once to invoke the feature. Type the new name as required and then click away from the sheet entry object or press

Enter to effect the change.

If attempting to graphically modify an object that has its Locked property enabled, a dialog will appear asking for confirmation to proceed with the edit. If the Protect Locked Objects option is enabled on the Schematic – Graphical Editing page of the Preferences dialog, and the Locked option for that design object is enabled as well, then that object cannot be selected or graphically edited. Click the locked object to select it then disable the Locked property in the List panel or disable the Protect Locked Objects option to graphically edit the object.

Non-Graphical Editing

The following methods of non-graphical editing are available.

Editing via the Sheet Entry Dialog or Properties Panel

Properties page: Sheet Entry Properties

This method of editing uses the associated Sheet Entry dialog and the Properties panel mode to modify the properties of a sheet entry object.

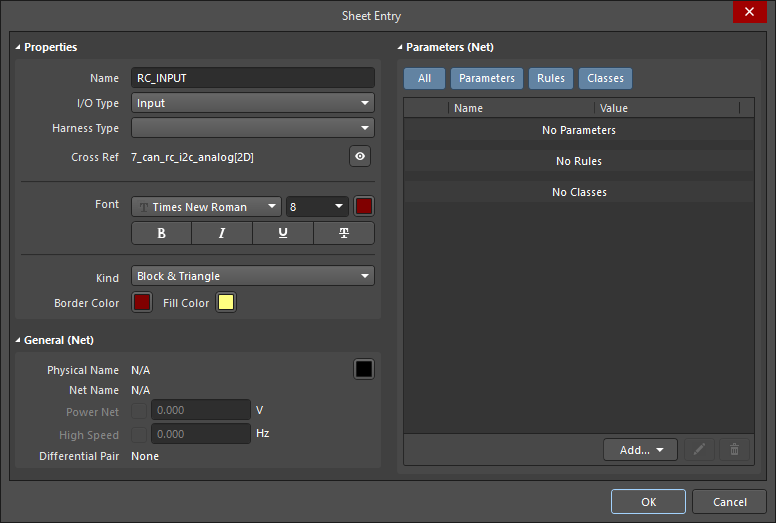

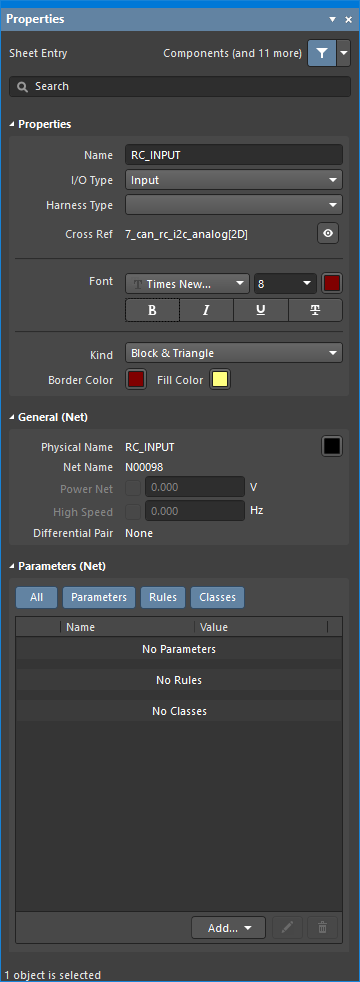

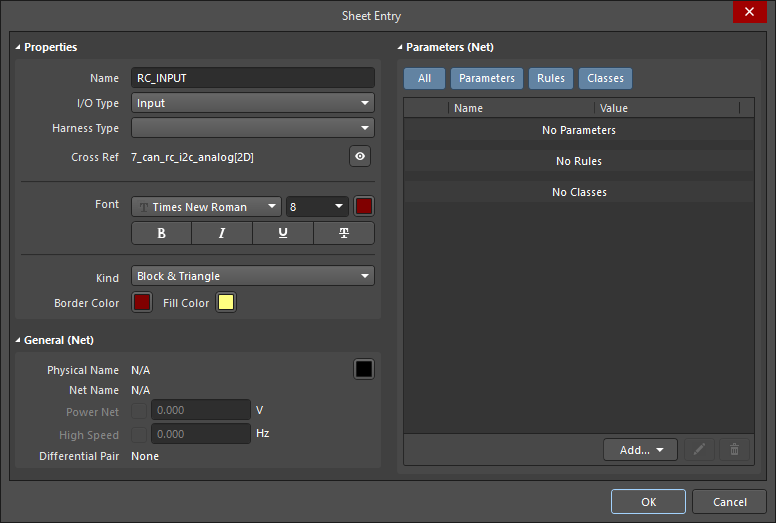

The Sheet Entry mode of the Properties (the first image) panel and the Sheet Entry dialog (the second image)

After placement, the Sheet Entry dialog can be accessed by:

- Double-clicking on the placed sheet entry object.

- Placing the cursor over the sheet entry object, right-click, then choosing Properties from the context menu.

During placement, the Sheet Entry mode of the Properties panel can be accessed by pressing the Tab key. Once the sheet entry is placed, all options appear.

After placement, the Sheet Entry mode of the Properties panel can be accessed in one of the following ways:

- If the Properties panel is already active, by selecting the sheet entry object.

- After selecting the sheet entry object, select the Properties panel from the Panels button in the bottom right section of the design space or by select View » Panels » Properties.

If the

Double Click Runs Interactive Properties option is enabled (default) on the

Schematic – Graphical Editing page of the

Preferences dialog, when the primitive is double-clicked or you right-click on a selected primitive then choose

Properties, the

Properties panel will open. When the

Double Click Runs Interactive Properties option is disabled, the dialog will open.

While the options are the same in the dialog and the panel, the order and placement of the options may differ slightly.

The sheet entry properties can be accessed prior to entering placement mode from the

Schematic – Defaults page of the

Preferences dialog. This allows the default properties for the sheet entry object to be changed, which will be applied when placing subsequent sheet entries.

Editing Multiple Objects

The Properties panel supports multiple object editing, where the property settings that are identical in all currently selected objects may be modified. When multiples of the same object type are selected manually, via the Find Similar Objects dialog or through a Filter or List panel, a Properties panel field entry that is not shown as an asterisk (*) may be edited for all selected objects.

Editing via a List Panel

Panel pages: SCH List, SCH Filter

A List panel allows you to display design objects from one or more documents in tabular format, enabling quick inspection and modification of object attributes. Used in conjunction with appropriate filtering – by using the applicable Filter panel, or the Find Similar Objects dialog – it enables the display of just those objects falling under the scope of the active filter – allowing you to target and edit multiple design objects with greater accuracy and efficiency.

Right-click Sheet Entry Actions

Right-click over a placed sheet entry to pop-up a context-sensitive menu, from which the following commands are available (on the Sheet Entry Actions sub-menu) that act on that sheet entry (or all currently selected sheet entries, where applicable):

-

Toggle Selected Sheet Entries IO Type – use this command to toggle the I/O Type for the sheet entry. It is also available by clicking Edit » Move » Toggle Selected Sheet Entries IO Type from the main menus.

Example of toggling sheet entry IO Type

The actual change depends on the current I/O Type as follows:

Unspecified remains Unspecified.Output changes to Input.Input changes to Output.Bidirectional remains Bidirectional.

-

Swap Selected Sheet Entries Side – use to relocate the sheet entry to the directly opposite side of its parent sheet symbol. The sheet entry's I/O Type is not changed by the swap. It is also available by clicking Edit » Move » Swap Selected Sheet Entries Side from the main menus.

Example of swapping sheet entry side.

Notes

- When a Sheet Entry is connected to a Signal Harness, the Sheet Entry becomes a Harness object. By default, the Sheet Entry will change color to match the color of the Signal Harness. Disable the Sheet Entries and Ports use Harness Color option on the Schematic – Graphical Editing page of the Preferences dialog to specify your own color for Sheet Entries or to use the default color.

- When a Sheet Entry is connected to a Harness Connector by a Signal Harness, the Harness Type in the Properties panel is automatically populated with the Harness Type of the Harness Connector. When a Sheet Entry is connected to a Port by a Signal Harness and the Port has a Harness Type declared, the Sheet Entry will become a Harness object and change to the color of the Signal Harness. If you move the Sheet Entry away from the Harness Connector and the Harness Type field is not populated, the Sheet Entry will revert back to the default color.

- Should you need to negate (include a bar over the top of) a sheet entry name, use one of the following methods:

- Include a backslash character after each character in the pin name (e.g.

E\N\A\B\L\E\).

- Enable the Single '\' Negation option on the Schematic – Graphical Editing page of the Preferences dialog, then include one backslash character at the start of the pin name (e.g.

\ENABLE).

- When instantiating multiple channels from the same sheet symbol, certain signals are repeated and sent individually to each instantiated channel. With respect to a sheet entry, a signal is repeated by using the Repeat keyword in the sheet entry's name (e.g.,

Repeat(Headphone)). The sheet entry is then wired to a bus, which in turn carries the individual signals to their correspondingly instantiated destinations.

- To quickly jump from a sheet entry to the corresponding port on the child sheet, Ctrl+Click the sheet entry object. In a schematic PDF output, click a sheet entry to navigate to a port on a child schematic page.

Sheet Entry PropertiesExpandCollapse

Schematic Editor object properties are definable options that specify the visual style, content and behavior of the placed object. The property settings for each type of object are defined in two different ways:

-

Pre-placement settings – most Sheet Entry object properties, or those that can logically be pre-defined, are available as editable default settings on the Schematic – Defaults page of the Preferences dialog (access from the button at the top-right of the design space). Select the object in the Primitive List to reveal its options on the right.

-

Post-placement settings – all Sheet Entry object properties are available for editing in the Properties panel and the Sheet Entry dialog when a placed Sheet Entry is selected in the design space.

If the

Double Click Runs Interactive Properties option is enabled (default) on the

Schematic – Graphical Editing page of the

Preferences dialog, when the primitive is double-clicked or you right-click on a selected primitive then choose

Properties, the

Properties panel will open. When the

Double Click Runs Interactive Properties option is disabled, the dialog will open.

While the options are the same in the panel and the dialog, the order and placement of the options may differ slightly.

Properties

General (Net)

Displays the properties of the nets assigned to the object. Update as needed.

The Power Net and High Speed fields become available after a directive has been added to the object.

Parameters (Net)

Creating a Multi-Sheet Design

As soon as you add a second schematic sheet to your project, you've created a multi-sheet design. If you are planning on creating a flat design without a top sheet, you simply keep adding schematic sheets to the project, and confirm that the Net Identifier Scope is set correctly.

If you want to use sheet symbols to reference lower-level sheets, you can either place the sheet symbol and manually edit it to correctly refer to the lower-level sheet, or you can use the various built-in commands to help, as described below.

Referencing the Child Sheet

It is the Filename property of the Sheet Symbol that references the lower-level sheet. Note that this field should only include the schematic filename, not the path to that file's location (this location data is actually stored in the Project file).

The Filename property links this sheet symbol to the child schematic sheet.

Note that the child schematic does not have to be stored in the same folder as the parent schematic. If the file is stored in a folder below the parent's storage folder then relative file referencing is used. If the file is stored in another location, then absolute file referencing is used. Take care when relocating files in such a project, or use the Project Packager to ZIP the files, as it will resolve file paths as it ZIPs the project.

Creating Hierarchy

The software includes a number of commands that allow you to build your multi-document, hierarchical structure quickly and efficiently. The commands you use will depend on your personal design methodology - which can be broadly classified as top-down, or bottom-up. These commands will be more efficient than creating the hierarchy manually, as they handle all the elements that are needed in the process, such as adding Sheet Entries, creating new schematic sheets, placing Ports, and so on.

Use this command to build the hierarchy in a top-down fashion:

- Design » Create Sheet From Sheet Symbol – use this command to create a new schematic sheet below the nominated sheet symbol. Ports are added to the child sheet to match any Sheet Entries found in the Sheet Symbol. Don't worry if you have not included all of the Sheet Entries in the Sheet Symbol yet, if more are added over time you can re-synchronize the Sheet Entries and Ports, as discussed below.

Use this command to build the hierarchy in a bottom-up fashion:

- Design » Create Sheet Symbol From Sheet – use this command to create a symbol from the nominated schematic sheet. To use this command, first switch to the sheet that will hold the new Sheet Symbol, then launch the command. The Sheet Symbol will include a Sheet Entry to match each Port it finds. If Ports or Sheet Entries are added or removed at a later stage they can be re-synchronized, as discussed below.

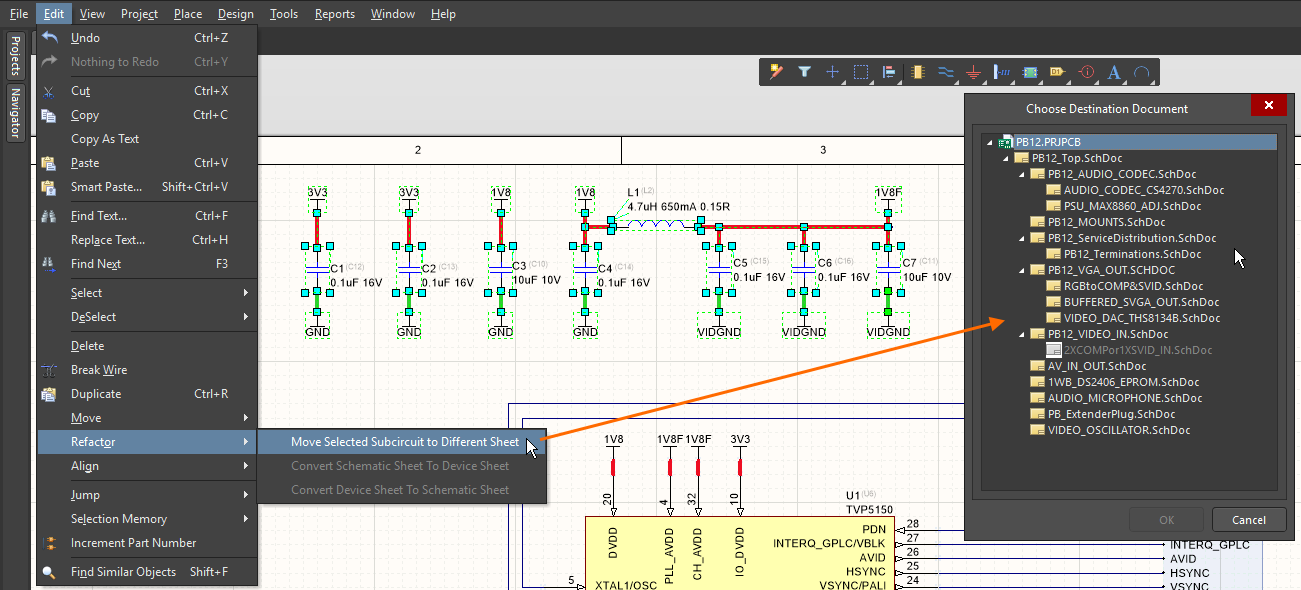

Use this command to reorganize how the circuity is placed in the design:

- Edit » Refactor » Move Selected Sub-circuit to Different Sheet - use this command to move the selected components and wiring to a different sheet in the project. The Choose Destination Document dialog will open, allowing you to choose any existing schematic in the project. This command is described in more detail below.