Placement - Component Clearance

This document is no longer available beyond version 4. Information can now be found here: Component Clearance Rule for version 5

Rule category: Placement

Rule classification: Binary

Summary

This rule specifies the minimum distance that components can be placed from each other. Component clearance includes clearance between 3D models used to define component bodies. In the absence of 3D bodies (or when the Check clearance by component boundary option is enabled in rule constraints), a closed contour formed by the primitives on the courtyard layer is used for rule checking. When there are no 3D Body objects or closed contours on the Courtyard layer defined, the bounding rectangle formed by primitives on the silk, copper and mechanical layers (excluding .Designator and .Comment text strings) is used.

Component clearance is calculated using accurate 3D meshing to define shape and contour for the component through its associated 3D body objects. These may be extruded 2D shapes. It is evident that using 3D bodies provides greatest accuracy when it comes to clearance checking, particularly in the vertical sense and in the context of complex component shapes.

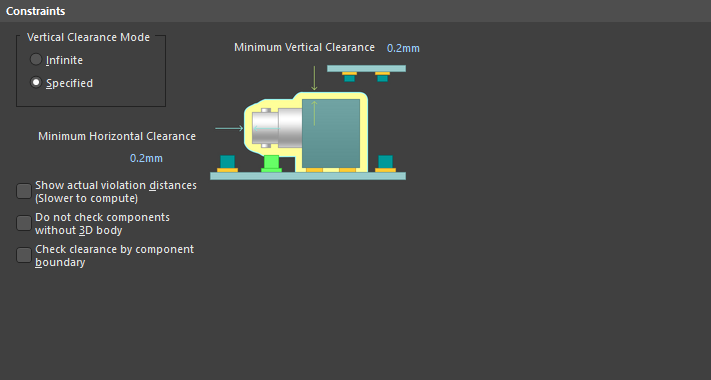

Constraints

Default constraints for the Component Clearance rule.

- Vertical Clearance Mode – two modes for specifying vertical clearance are available:

- Infinite – clearance checking is performed using a value representing infinity. This means that any components placed above or below will be in violation. An example of use would be a board that has an adjustment mechanism that must remain accessible. Using this rule on that component will cause a violation against any components that protrude into the area above or below the component.

- Specified – clearance checking is performed using the exact shape defined by the component 3D bodies or component footprint properties. When using 3D bodies, it is possible to have an acceptable overhang between one component over another, provided they are not in violation. With this mode enabled, the following constraint becomes available:

- Minimum Vertical Clearance – the value for the minimum permissible clearance, in the vertical sense, between placed components in the design.

- Minimum Horizontal Clearance – the value for the minimum permissible clearance, in the horizontal plane, between placed components in the design.

-

Show actual violation distances – enable this option to show lines between the points of greatest violation between components. The distance of the line is displayed and can be useful in calculating the distance required to move an object to resolve the violation.

- Do not check components without 3D body – enable this option to exclude components without a 3D Body from being clearance checked by this rule.

- Check clearance by component boundary – enable this option to use the component boundary for component clearance checking.

How Duplicate Rule Contentions are Resolved

All rules are resolved by the priority setting. The system goes through the rules from highest to lowest priority and picks the first one whose scope expressions match the object(s) being checked.

Rule Application

Online DRC and Batch DRC.

Notes

- An extruded (simple) 3D body is a polygonal shaped object that can be placed in a library component or a PCB document, on any enabled mechanical layer. In a component footprint, it can be used to specifically define the physical size and shape of a component in the X, Y and Z-axes.

- Multiple 3D body primitives may be used to define shapes of any complexity. This can prove especially useful in the vertical sense, as it allows you to vary the height of a component in different regions of that component.

- To allow collision of the components scoped by a Component Clearance design rule (i.e. to not report component collision during design rule check), set both Minimum Horizontal Clearance and Minimum Vertical Clearance option values to

0.