Altium Designer: Your Multilayer PCB Stackup Planner

Table of Contents

Newer PCBs are rarely designed on one or two layer boards. With the high density of connections and the number of components that are used in modern PCBs, your next design will probably be a multilayer PCB. If your next device has an odd form factor, then you will probably be using a rigid-flex PCB. Both of these types of PCBs require the right stackup procedure. This means you need PCB design software with an intuitive stackup manager. When you work with Altium Designer, your multilayer stackup easily synchronizes directly into your PCB layout.

ALTIUM DESIGNER

A PCB design software package with the best multilayer PCB stackup management tools.

The best multilayer stackup strategy for your next device depends on a number of factors. No stackup strategy will be able to accommodate every design, routing, or EMC requirement simultaneously. Your multilayer PCB device application will also determine the best layer stackup strategy in your multilayer PCB. When you work in an integrated design environment, you’ll have access to the best stackup tools that communicate directly with your layout, simulation, and rules-checking features.

Planning Your Multilayer Stackup

With both single layer and multilayer PCB design, you’re going to have to plan out component and copper placement. Even a single layer printed circuit won’t go into PCB manufacturing without significant planning going into the board layout. PCB design requires consistent caretaking of component placement throughout the design of your circuit and will continue to be so as you move into multilayer PCBs. Double-sided PCB and Multilayer PCBs just enable things like buried vias, keeping track of holes, and planning for thickness and outer layers. However, it also requires additional layout concepts, for example, an inner layer on a multilayered PCB will have an increased risk of crosstalk.

Planning your layer PCB stackup strategy in your next multilayer PCB will typically alternate between signal and power/ground planes, with each layer separated by either dielectric core or prepreg. Rigid-flex PCBs are inherently multilayer boards that come with their own stackup requirements. The goal is to suppress EMI and crosstalk between layers while simultaneously allowing for efficient routing between layers.

Multilayer PCB Stackup Strategies

Multilayer PCB design is as much an art as it is a science, and your entire design process will depend on your layer arrangement. You’ll need to include vias to route between layers, choose an appropriate power/ground plane pair arrangement, and generate deliverables with all of your information for your manufacturer. All of this is possible when you work with the best PCB design software with an excellent layer stack manager.

- Each layer in your stackup has its own functionality, which needs to be specified in your multilayer stackup. Learn more about multilayer stackup strategies.

- Rigid-flex PCBs use multiple boards and require their own multilayer stackup strategy. Learn more about the differences between multilayer and multi-board stackup.

- Learning about multilayer design can take your PCBs in new directions. See more multilayer PCB design tips.

The layer stackup editor in Altium Designer

Routing in Multilayer PCBs

Routing in your multilayer PCB requires judicious use of vias in our to pass signals between layers. Certain layout rules need to be followed, depending on your layer stackup. The right stackup strategy can reduce crosstalk and suppress EMI in your signal layers, ensuring that your signals will remain stable against external fields and noise. You’ll want to make sure your multilayer PCB circuit board is safe before copper placement so as to avoid wasting time and money.

Rigid-flex PCBs are inherently multilayer devices, and many of the same design strategies that apply to a typical multilayer board also apply to rigid-flex PCBs. Some design guidelines on a flex ribbon or even on a flex PCB need to be considered before jumping into this less common area of PCB design. Your design software should be material agnostic, giving you the ability to implement all the best design features on any board, regardless of stackup strategy.

The Best Layer Stackup Strategies Takes the Best PCB Design Software

Once you’ve designed your multilayer PCB layer stack around your particular application, it’s time to implement it in your PCB design software. You’ll need an intuitive layer stack manager that allows you to visually examine your layer stackup. You shouldn’t be limited to FR4; your stackup manager should allow you to use any material. Since routing between layers requires vias, your design software needs to integrate via definitions into your board layout.

- Including vias in your multilayer design is essential for routing between layers. Your design software should include standard and customizable via options. Learn more about designing vias for your PCB.

- Your stackup manager should include material options you need for multilayer flex and rigid-flex PCBs. Using the right design software and techniques will help you be successful. Learn more about design techniques for flex and rigid-flex PCBs.

- Should you use multiboard or multilayer design (or both)?. Understanding the tradeoffs can help ensure that you design the best device for your application. Learn more about choosing between multiboard and multilayer design.

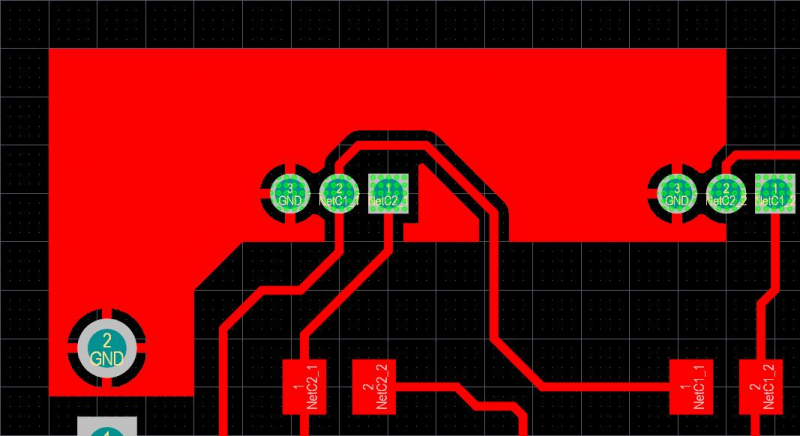

Polygon pour editing in Altium Designer

Integrating Design and Multilayer Stackup in Altium Designer

Multilayer stackup is just the first step in multilayer PCB design. You need tools to define your board size, capture your schematic, accurately place components, route your traces, and manage your component data. Since multilayer PCBs tend to operate at high speed, high density, and/or high frequency, simulation, and analysis tools can help you validate your designs and diagnose signal problems before you move to production.

Altium Designer gives you access to the best layer stackup, CAD, and simulation tools, and all within a unified design environment. Your simulation and analysis tools interface perfectly with your layout editor, giving you the power to fully analyze your multilayer PCB and bring it closer to perfection. When you move to production, Altium Designer generates manufacturing outputs, bills of materials, and Gerber files for your manufacturer, and all within a single software platform. Any PCB manufacturer will be happy to work with your circuits during the manufacturing process.

Get Access to the Best PCB Features in Altium Designer

Forget about moving between multiple modules or programs when working on your designs. Your design software should give you the capabilities to access any of the tools you need within a single interface. Other design environments claim to be unified, yet you still have to move between modules and purchase critical features as add-ons. You’ll have the power to design top-quality mulitlayer PCBs when all your design tools are integrated into a single platform.

- Your multilayer PCB requires a customized layer stackup. Altium Designer presents your layer stackup and properties in a single intuitive interface. Learn more about the layer stackup tools in Altium Designer.

- With Altium Designer, all your design tools are integrated within a single software platform. You’ll have the flexibility to customize your stackup and interface with other features when you work in a unified design environment. Learn more about the unified platform in Altium Designer.

- Taking your multilayer board from design to a final product requires the best tools for generating accurate manufacturing and assembly outputs. Altium Designer generates all these outputs for you, and even provides you with supply chain information. Learn more about generating manufacturing outputs in Altium Designer.

Working in a unified design environment gives you access to all the tools you need to design the best multilayer PCB layouts within a single design platform. You’ll have access to the best CAD, schematic capture, routing, and data management tools without having to move between different programs or modules. All of these features are integrated within your design rule checking features, ensuring that your next multilayer PCB design will be a success.

Whether you need to build a simple board with one layer, a multi-board PCB with multiple layers, or anything in between, a great PCB design software package like Altium Designer contains all the tools you need. You’ll have access to all the simulation tools demanded by the PCB design industry in Altium Designer.