Best Software for PCB Design and Manufacturability (DFM) Guidelines

Table of Contents

Getting your circuit board to manufacturing requires following certain manufacturability guidelines. Once you gain an understanding of DFM standards, you will be in a much better position to design your circuit boards to meet DFM expectations. As a PCB designer laying out a circuit board, you’ll find yourself having to manage these guidelines and standards to get your board through the manufacturing and assembly process. Altium Designer makes this process easy thanks to its integrated design rules engine. Here’s how this works and how it helps you create high-quality products.

ALTIUM DESIGNER

PCB design software to help you prepare your circuit board for manufacturing and assembly processes.

DFM, or Design for Manufacturability, is a term that gets thrown around quite a lot these days in the world of printed circuit board design. The question is: what is DFM really? For some, it is making sure that the PCB can be fabricated correctly while for others it’s making sure that the PCB can be assembled correctly. Other people would say that it is making sure that the correct components are available when needed while yet others would say that it refers to in-circuit testing. The answer of course is that it is all of the above, and much more as well.

You might engineer your boards to a certain set of constraints, but your manufacturers may need something different to ensure your board will pass a design review. When you fully understand the DFM rules from your list of PCB manufacturers, you can get through a design review and fabrication with high yield and without delays. With the DFM tools in Altium Designer, you can ensure your PCB prototype or full-scale manufacturing run will be completed successfully.

Managing Design Guidelines and Standards

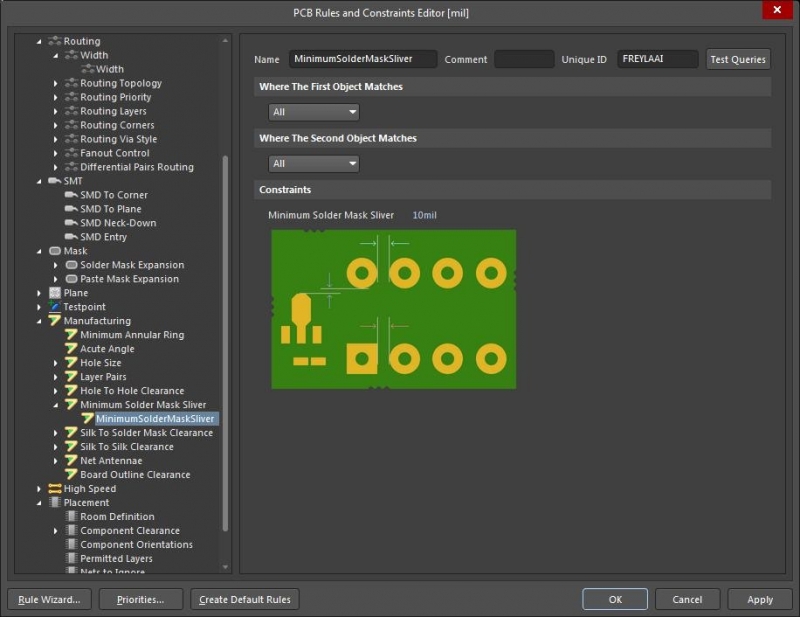

ECAD software can allow designers to create any board layer stacks, and copper printed circuit layout without enforcing DFM rules. Before you start your printed circuit layout, you need to make sure your circuit board design tools will obey important DFM rules. These rules apply to everything from material thickness to solder masks and spacing between vias, holes, parts, and much more.

Working with Manufacturers to Develop Good DFM Practices

If you have a list of PCB manufacturers you want to use, then you need to make sure your design is aligned with their PCB design and manufacturing guidelines. The first thing that you should do is to work with your PCB manufacturer to understand what they need in your PCB layout. Take time to learn about the fabrication process and the documentation your fabricator needs for a successful production run.

Once you’ve obtained these requirements from your fabricator, you need to encode these requirements as design rules in your printed circuit design software. Whether you’re designing a PCB prototype or planning a full-scale manufacturing run, obeying DFM rules helps you build high-quality products with high yield.

- The right printed circuit design software will help you spot some common layout problems that will violate DFM rules. You’ll want to avoid some common pad and via problems in your PCB prototype.

Learn more about common pad and via problems that can be avoided.

- You’ll also need to design your circuit board to accommodate the assembly process, including through-hole technology components and surface-mount parts.

Learn more about avoiding common assembly process problems in your PCB.

- Once you’ve sent your circuit board out for fabrication and assembly, your manufacturer will check your board for compliance with their DFM standards and their fabrication and assembly processes.

Learn more about getting your printed circuit board through a DFM check.

Altium Designer includes DFM tools in your design rules to help prevent errors on pad and vias before manufacturing and assembly.

Preparing for Manufacturing with Rules-Driven Design Software

If you ever want your circuit board to be more than just a printed circuit layout on a computer screen, you’ll need to create documentation for PCB fabrication and assembly. You’ll need to take information in your schematic and layout and generate a complete set of PCB fabrication deliverables. Planning for manufacturing and the assembly process requires multiple files in standard formats, such as Gerber files, bills of materials, assembly instructions, and much more.

Your printed circuit design software should make it easy to construct a bill of materials by importing component information directly from your libraries. Your DFM tools also need to take your PCB footprint information to ensure your board will not violate your DFM rules. Only the best modern circuit board design tools will include DFM tools to inspect all aspects of your layout.

Select Components and Prepare for Assembly in Altium Designer

Altium Designer includes tools you need for component selection so that you can control costs and lead times. Altium Designer’s layout editor will give you precise control over manufacturing details related to your through-hole technology and SMT components, such as solder paste and annular rings for holes and vias on components. You can also instantly create high-quality assembly drawings from your PCB layout. This gives you everything your fabricator needs to source and assemble your new circuit board.

- If you need to produce a PCB prototype, your PCB design software should allow you to optimize your bill of materials for rapid prototyping.

- Once you’ve tested your prototype circuit board, you need to scale up your order to full-scale fabrication and assembly. You’ll need complete sourcing and assembly information for your circuit board to prevent delays and cost overruns.

See how parts supplier information helps you manufacture at high volume successfully.

- Creating a between the needs of engineering and manufacturing, and you need to be prepared to manage this relationship.

Learn more about creating a comprehensive manufacturing documentation package.

Sourcing parts for your circuit board manufacturing run with Altium Designer

Get to PCB Fabrication Quickly With Altium Designer

Once you’ve determined your DFM requirements, you need to finish your design with as few mistakes as possible. When you use Altium Designer, your DFM requirements are encoded as design rules into your PCB design and layout features. This helps you prevent simple errors that can derail a PCB prototype or full-scale manufacturing run. Altium Designer makes it easy to generate standardized deliverables for any manufacturer. You can rest assured that your circuit board will be produced correctly and that these manufacturers are familiar with Altium Designer’s output format. Because the design engine is integrated throughout your circuit board design tools, you can rest assured your circuit board layout will obey DFM rules.

Altium Designer’s Unified Environment Makes DFM Easy

Altium Designer is the tool of choice for helping you through all aspects of PCB design when working with DFM requirements. All the design features in Altium Designer are governed by a full set of design rules and constraints under your control so that you can make sure to design to the specific DFM guidelines that you need.

- Altium Designer provides everything you need for printed circuit design and PCB fabrication in a single program.

Learn more about the unified design and manufacturing features in Altium Designer.

- All the printed circuit design and layout features in Altium Designer work together in a single program thanks to a rules-driven design engine. This allows you to implement your DFM rules and check them instantly as you create your PCBs.

Learn more about rules-driven PCB design in Altium Designer.

- The 3D ECAD/MCAD tools in Altium Designer let you create a high-quality circuit board and check your board inside your enclosure before manufacturing.

Altium Designer’s native 3D environment lets you view your panelized boards when preparing for PCB fabrication.

Working in a rules-driven design environment is the easiest way to make sure you follow all the right PCB design and manufacturing guidelines. Whether you’re designing a single PCB prototype or a complex multi-board system, Altium Designer has the tools you need to get through PCB fabrication and assembly.

Altium Designer on Altium 365 delivers an unprecedented amount of integration to the electronics industry until now relegated to the world of software development, allowing designers to work from home and reach unprecedented levels of efficiency.

We have only scratched the surface of what is possible to do with Altium Designer on Altium 365. You can check the product page for a more in-depth feature description or one of the On-Demand Webinars.