PCB Prototype Board Layout Software That Helps You Scale

Table of Contents

- Which Software is Needed for PCB Prototypes?

- Professional Designers Use Professional Applications

- Professional Applications Have Integrations

- Migration Has Mixed Reviews

- Starting the PCB Prototyping Process

- Types of PCB Prototyping Services

- Altium Designer is a Single Prototyping and Production Solution

- Start With Front-End Design Solutions

- PCB Prototyping and Production Unified with the Best PCB Layout Tools

Companies working on the newest hardware platforms can't instantly scale from zero to millions of units. They will need to build PCB prototypes in order to qualify their new systems and ensure the system will meet many compliance metrics. Prototyping will be the first attempt to prove an engineered system will work as intended, and that it can produce functionality that aligns with user experience expectations.

Startup companies who are just getting into the electronics space will need to produce their own prototypes, but lack of familiarity with the required software packages creates a perception of differences between prototype and production board design software.

Instead of looking for different types of PCB layout packages to produce prototypes versus moving to scale, start with a unified design package that can get you into production at any volume. Professional PCB design software that supports prototyping, low volume production runs, and scaling to millions of units only needs to perform a few high-level tasks:

- Importing of schematic designs into a PCB layout

- Creation of a high-quality layout with DRCs to ensure constraints are satisfied and a board is manufacturable

- Generation of standardized deliverables for PCB manufacturers and PCB assembly services

Which Software is Needed for PCB Prototypes?

If you look through the ECAD software market, there is no specific software for prototypes versus production. Technically speaking, any ECAD package can be used to produce a design and manufacturing files for a product to be manufactured at any volume. Therefore, we don't really have prototype-specific CAD applications.

That being said, many new designers and startups are likely to look at the options and pricing for ECAD applications, and they might pick a lower-end platform to help them build a prototype. It's also common for a designer to select an open-source design application, particularly in hardware startups. Later, once the prototype is proven, budget is allocated to continued development, and a path to production is determined, they might purchase a license to a professional-level design platform.

Here's why you should not go this route and just start with a professional-level design platform.

Professional Designers Use Professional Applications

Aside from saving time by sticking to a single design application, it's much easier to find and engage the best talent when you use the best design tools. Startups shouldn't engage a hobbyist using open-source design software when they want to disrupt an entire industry. The major PCB design software vendors have taken major steps to ensure their established users are operating at the cutting edge so that they can support innovators in established companies and startups. If you want to engage with one of these contractors or hire the best design employees, then your company needs to use a professional-level design application.

Professional Applications Have Integrations

Modern electronics design teams are firmly multidisciplinary, requiring collaboration between different engineering disciplines to build a new product. This spans between electronic engineering and mechanical design, PCB design and simulation, and even into collaboration with your manufacturer. PCB designers need these tools to stay maximally productive and address all aspects of a new product design. The most commonly used integration is with industry-leading mechanical design tools using ECAD-MCAD collaboration tools.

Solidworks integrations through your PCB design software allows an electronics design team to work with mechanical designers.

Migration Has Mixed Reviews

When your team does decide to get away from a simpler prototyping application and into a professional design tool, you might want to convert your prior designs into a new file format. Pro design tools have migration features that convert between different design file formats, and this is required because there is no "universal" CAD format that can be opened in all design tools.

Not all ECAD applications will support all migration from all other applications. You might quickly find that you are unable to convert to your desired application, and this leaves you to recreate the design in the new ECAD application. This takes additional time and effort that no one wants to spend, especially if you're already going through trainings on the new application.

If your platform does handle migrations, then the results could be mixed and some cleanup is typically required for the converted PCB layout files. It's always hard to predict exactly what updates or fixes will be needed in order to use the converted files for production. Make sure you learn about the migration capabilities of your ECAD application before starting with a lower-quality design tool.

EAGLE to Altium Designer migration

Starting the PCB Prototyping Process

PCB design software will generate the files you need for a prototyping run without requiring an external program. All PCB design applications support Gerber files; some support the more advanced ODB++ and IPC-2581 formats. Before your design can be put into production with a PCB prototyping service, a set of standard deliverables needs to be generated from your design data and sent to your fabricator for a DFM check. Designers need to create the following set of deliverables:

- Gerber files generated from your PCB layout in standard formats (RS-274-X or X2)

- Alternatively, ODB++ or IPC-2581 files can be generated

- A bill of materials with complete procurement information, component descriptions, and acceptable alternatives

- PCB testing data and testpoint descriptions

- Pick-and-place data for programming automated assembly machines

- NC drill files for placing vias and mounting holes in the PCB stackup

- An IPC-compliant netlist that is used in automated inspection

- Fabrication and assembly drawings showing a PCB stackup, component locations, reference designators, and fabrication notes

Once you generate these files, your data can be sent to a PCB prototyping service to begin quoting and DFM checks. Most manufacturers that have a user-facing quote portal will be able to provide very accurate quotes once you upload your design files. Once the design passes DFM, you can begin procuring components and consign them to an assembly house. The best PCB design and layout software will help you move through this process faster as you can quickly generate these standard deliverables before you get a quote for your design.

Types of PCB Prototyping Services

Prototyping is an important step in product development, and it gives you a chance to test the functionality of your PCB before it's deployed in a production environment. There are many PCB prototyping services that offer varying levels of service, price ranges, and lead times. The prototyping service you use might only be a fabricator, meaning you'll need to contract with an assembly house in order to finish and receive your PCBA prototype.

Make sure to pay attention to the lead time for your prototype as some services offer different options. There are many rapid prototyping services that aim for the shortest possible lead time on your fabricated boards, but these services will be more expensive than other PCB prototyping services with long lead times. Rapid prototyping services will use standard stackups to eliminate NRE tasks and expedite your board with standard in-stock materials. In addition, make sure you plan for assembly with an external service if needed as not all rapid prototyping services will offer PCB assembly in-house.

Prototype assembly will go through the same process as in high-volume production, so you will have a look into the volume manufacturability of your system.

Altium Designer is a Single Prototyping and Production Solution

Altium Designer was created with a single goal: to be adaptable to any stage of the product development process, starting from front-end engineering and culminating in high-volume production as part of a go-to-market strategy. Everything needed to create CAD libraries, engineer all circuitry, design a PCB layout, and export data for manufacturing is included as standard features in Altium Designer. You won't need to shift from a basic prototyping software package into a production solution: start with the best PCB design software and you'll yourself on a streamlined path to volume production.

Start With Front-End Design Solutions

To help startups and established companies stay maximally efficient, Altium Designer offers a complete suite of front-end engineering and design solutions that take engineers from concept to PCB layout. When you use Altium Designer, you can bring design concepts from the lab into PCB prototyping quickly and easily. Your PCB layout features integrate with a complete set of manufacturing features, giving you the features you need to make the transition from prototype boards to a final product produced at scale. Everything you need to create high-quality PCBs and produce them at scale can be found in Altium Designer.

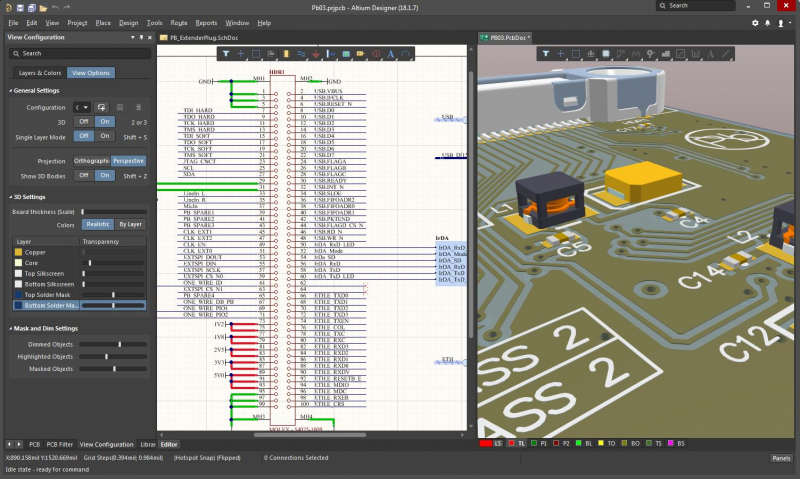

The PCB design interface in Altium Designer.

PCB Prototyping and Production Unified with the Best PCB Layout Tools

Altium Designer eases the process of PCB design with hierarchical multi-channel design support, the best PCB layout editor, 3D design features, and integrations with MCAD, simulation, and PLM. Everything needed to create the best designs and prepare for production at scale is included in Altium Designer. Startups, established PCB design services firms, freelance designers, and large enterprises all trust Altium Designer to conceive and build the latest technologies.

- Only Altium Designer integrates a complete set of design and manufacturing tools into a single application. You’ll have the design features you need to prepare for prototyping and manufacture boards at full scale.

Learn more about rules-driven PCB design and manufacturing in Altium Designer.

- The native 3D PCB design features in Altium Designer are ideal for taking your prototype boards and transforming them into high-quality finished products that can be manufactured at scale.

Learn more about the native 3D PCB design features in Altium Designer.

- When you’re working on a prototype PCB assembly for advanced products with multiple designers, the collaboration applications can help you stay organized and help you source components before sending your boards to assembly services.

Learn more about the sharing, collaboration, and data governance features on Altium 365.

Verify your design in 3D with Altium Designer

When you need to complete your PCB design and prepare your board for the PCB fabrication process, you need the complete set of design, layout, and manufacturing tools in Altium Designer®. No other PCB design platform gives you the capability to fabricate a prototype board, production boards, and PCB assembly services data in a single program.

Altium Designer on Altium 365 delivers an unprecedented amount of integration to the electronics industry until now relegated to the world of software development, allowing designers to work from home and reach unprecedented levels of efficiency.

We have only scratched the surface of what is possible to do with Altium Designer on Altium 365. You can check the product page for a more in-depth feature description or one of the On-Demand Webinars.