How to Design and Route Your RF Filter PCB Layout

RF PCBs and mixed-signal systems are challenging for many designers. Careful attention must be paid to the PCB stackup design, process for designing transmission lines, placement of components, and floorplanning the PCB layout to ensure predictable return path. Many RF PCB layout designs will include printed elements, like an RF filter, antenna, isolation structures, and unique waveguide geometries.

RF systems can make copious use of RF filters and matching network designs to ensure signal quality. If you need to design an RF PCB layout with RF filter circuits and structures, your design tools will play a major role in determining the system’s performance and they can help you stay productive. Once you’ve determined your relevant signal bandwidth and you’ve determined RF filter requirements, your design tools can help you stay productive as you create your RF PCB layout.

If you want to learn more about working with your CAD tools to design RF systems, read our guide on RF filter PCB layout. The best set of automated PCB design tools will help ensure your design meets performance goals and is manufacturable at scale.

ALTIUM DESIGNER

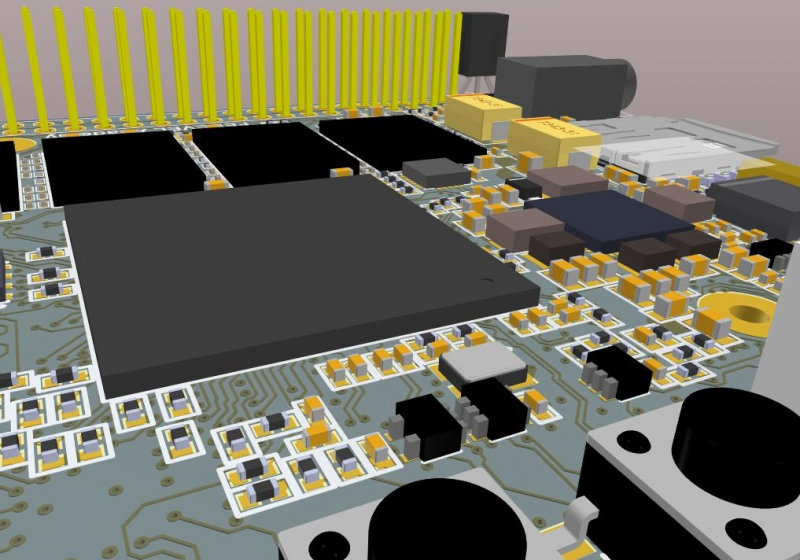

A unified PCB design application with a full suite of PCB layout and manufacturing tools for professional RF design teams.

Many modern designs include mixed-signal capabilities, including low-speed digital, high-speed digital, and high-frequency analog spanning into the GHz range. These advanced designs need careful layout and routing, as well as careful signal manipulation with RF components. Designs with isolation structures, antennas, RF filters, and other components must be carefully designed to meet system impedance and signal quality goals, which can be difficult given the many causes of signal loss at very high frequencies.

Your PCB design tools are critical for ensuring you can get through the RF design process efficiently and with a high-quality, fully-functional RF PCB layout. Altium Designer is here to help guide you through the RF PCB design process and create your RF filter PCB layout to ensure signal integrity in your finished design. Before looking at Altium Designer’s capabilities, it helps to understand the RF PCB design process and how RF PCB filters play a role in high-frequency analog and mixed-signal systems.

The RF PCB Design Process

RF PCB designs at any frequency carry a range of PCB layout requirements and must follow similar processes. Because so many RF designs will need to manipulate RF signals, the design team needs to consider signal bandwidths to determine RF filter design requirements in their PCB layout. RFdesigns usually proceed under the following process:

- Determine signal bandwidths: This will determine what type of filtering is needed in the PCB layout. It also determines the dielectric constant as dispersion must be considered when planning the design.

- PCB stackup design: Once the signal bandwidth and dielectric constant are determined, the PCB stackup can be designed to ensure required PDN impedance and impedance of transmission lines.

- Schematic capture and component placement: If schematics are ready and components have been selected, the design can be captured in a blank layout and the designer can start arranging components.

- Filter and antenna placement: Printed elements like RF antenna structures and RF filter designs need to be carefully designed and placed in the PCB layout to ensure they have the desired signal characteristics.

- Routing: Once components are placed in the PCB layout, the design needs to be routed with consistent transmission line impedance.

- Documentation and manufacturing prep: A finished design needs to be prepared for manufacturing by generating a set of standardized deliverables from design documents.

RF filters take special care when designed as printed structures on a PCB, just an antenna, via fence, or other isolation structure. When designed from discrete components, there are important aspects of signal integrity that must be considered when creating the PCB layout.

RF Filter PCB Layout Structure

Before arranging components in the PCB layout for RF filter circuits, the PCB stackup needs to be created to provide the desired system impedance within the system’s signal bandwidth. In addition, an RF filter should be simulated in a schematic sheet to examine how the filter topology will influence signal behavior.

Altium Designer’s schematic editor, component libraries, and integrated simulation engine are ideal for creating filter circuits from generic or real components. There are many common topologies for RF filters, which involve placement of inductive or capacitive elements in a PCB layout. When designing an RF filter in the schematic, generic components are often used to simulate real components or structures on a PCB as they will determine how a signal interacts with these filtering structures. The components can be placed on the PCB during the layout stage to give the desired RF filtering characteristics.

- Dielectric constant dispersion in your PCB stackup material will determine transmission line impedance and how you match feedlines to your RF filter in your PCB layout.

- Your RF PCB layout begins with designing a high-quality stackup. Your stackup will determine system impedance and losses for your transmission lines.

Learn more about PCB stackup design in your RF circuit board.

- Some basic simulation tools during schematic design can help you design and evaluate your EMI filter designs at RF frequencies.

Learn more about running EMI filter simulations in Altium Designer.

Altium Designer’s Layer Stack Manager helps you prepare your PCB for RF routing and layout.

RF Filter PCB Layout and Routing

Once your PCB stackup is designed and filtering requirements have been determined, it’s time to create an RF PCB layout for your filtering circuits. Filter circuits and impedance matching networks have some specific requirements that need to be considered during layout and routing:

- Floorplan the design: Keep the RF analog section away from digital components and ensure the return path from the digital section does not overlap into the digital section.

- Use short traces: This is less about loss and more about ensuring traces between components and printed elements do not act like transmission lines at high frequencies. When traces are long, signals can reflect between components and create strong radiation at certain frequencies.

- Account for parasitics in the layout: The presence of parasitics in a high-frequency design cause the real impedance to be different from the design impedance. This requires using techniques like network parameter analysis and field solvers to understand parasitics.

- Account for parasitics in components: Components with reactive impedance have parasitics that become evident at high frequencies. This is very important when selecting capacitors and inductors.

- Place RF components above a ground plane: The goal here is to ensure isolation and consistent input impedance seen by a signal as it enters the RF filter.

Because impedance control is so important to RF layout and routing, your design tools need to be able to evaluate design impedance and enforce the necessary impedance profile. The best design tools can do this and provide simulation capabilities to examine signal behavior as you create your RF PCB layout.

Ensure Impedance Control in RF PCB Layout and Routing

The traces between components and printed circuit elements in an RF filter circuit need to be carefully routed while ensuring controlled impedance in the PCB layout. The best routing tools can take your stackup design data and enforce a specific impedance profile as traces are routed. This is a central aspect of signal integrity in high-speed digital and high-frequency analog design, and it will ensure your RF filter circuits and structures have the right bandwidth and filtering behavior.

- When routing traces in your RF filter design, make sure you use design software that enforces impedance control in your PCB design.

Learn more about Altium Designer’s interactive controlled impedance routing utilities.

- The best design tools will let you design unique RF interconnects and filtering structures, such as substrate integrated waveguides and electromagnetic band gap structures.

Learn more about using RF interconnects and isolation structures for filtering and isolation.

- Once your design gets to ultra-high frequencies, there are alternatives to traditional waveguides with low loss and high isolation, like mode-selective transmission lines.

Altium Designer’s rules-driven design environment lets you apply impedance profiles to your RF interconnects.

The Best Design Software for RF PCB Layout

In the list of RF PCB design and layout requirements shown above, we can determine several design rules that need to be carefully followed. Modern PCB design tools should operate by giving designers the ability to customize their design rules to comply with their specific application requirements. For RF PCBs, this requires considering everything from impedance to ground plane return path tracking to ensure signal integrity, RF isolation, and stable power in your circuit board’s PDN.

Altium Designer’s complete set of PCB layout and routing tools are built on top of a rules-driven PCB design engine, giving designers everything required to ensure conformance to their design and layout requirements. The design rules engine in Altium Designer checks your PCB layout as you create it, identifying design rule violations as your components are arranged and traces are routed. The rules-driven design engine ensures all your tools can work together in a single application, giving you everything you need for RF filter PCB layout and any other advanced PCB.

Altium Designer Has the Best RF PCB Design Utilities

The rules-driven design engine in Altium Designer unifies every design tool you need into a single application. When you need to create a high-frequency analog system or mixed-signal PCB, the rules-driven design tools in Altium Designer keep you productive and ensure your design meets your application requirements. Best of all, you won’t have to use external programs for RF filter design, simulation, and impedance control; everything you need can be found in Altium Designer.

- Altium Designer’s unified PCB design environment includes everything needed to create simple circuit boards and advanced RF PCBs in a single application.

Learn more about Altium Designer’s unified design environment.

- Altium Designer includes an integrated field solver from Simberian, giving designers an integrated tool for ultra-accurate impedance calculations in RF PCBs.

Learn more about the integrated field solver from Simberian in Altium Designer.

- Altium 365 lets you instantly share design and production data for your RF circuit board through Altium Designer or on the web.

Learn more about sharing your PCB project data with Altium 365.

Altium Designer provides everything needed for high-speed PCB design and RF PCB design ina single application.

Designing an RF filter PCB layout can be difficult without the right design software. Altium Designer gives you the tools you need for digital, analog, and mixed-signal design in a single application. You can stay productive while designing RF systems and prepare for manufacturing when you use Altium Designer.

Altium Designer on Altium 365 delivers unprecedented integration to the electronics industry until now relegated to the world of software development, allowing designers to work from home and reach unprecedented levels of efficiency.

We have only scratched the surface of what is possible to do with Altium Designer on Altium 365. You can check the product page for a more in-depth feature description or one of the On-Demand Webinars.