Working with the Minimum Annular Ring Design Rule on a PCB in Altium NEXUS

Created: 三月 23, 2017 | Updated: 十二月 26, 2019

| Applies to versions: 1.0 and 1.1

您正在阅读的是 1.1. 版本。关于最新版本,请前往 Working with the Minimum Annular Ring Design Rule on a PCB in Altium NEXUS 阅读 4 版本

Rule category: Manufacturing

Rule classification: Unary

Summary

This rule specifies the minimum annular ring required for a pad or via. The annular ring is measured radially, from the edge of the pad/via hole to the edge of the pad/via (also referred to as the land perimeter).

Constraints

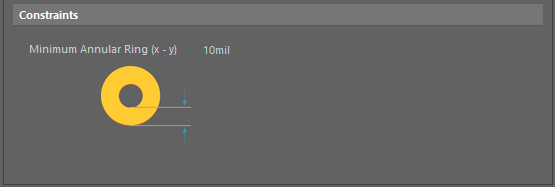

Default constraints for the Minimum Annular Ring rule.

Default constraints for the Minimum Annular Ring rule.

- Minimum Annular Ring (x-y) - the minimum value for the annular ring around the pads/vias targeted by the rule.

How Duplicate Rule Contentions are Resolved

All rules are resolved by the priority setting. The system goes through the rules from highest to lowest priority and picks the first one whose scope expression matches the object(s) being checked.

Rule Application

Online DRC and Batch DRC.

Notes

- Different fabrication houses will undoubtedly use varied and differing manufacturing technologies and equipment. Average performance houses may offer design specifications allowing a 10mil minimum annular ring. High performance houses may be able to reduce that figure down to 5mil. If pad and via holes are laser-drilled, as opposed to mechanically drilled, then the value for the minimum annular ring may be reduced further still.

- The class of board you are designing will also play a part in the value required for the minimum annular ring. For example, if your design is of IPC Class 3 standard, which refers to high reliability electronics products, the required minimum annular ring is 2mil.

- If you do have to reduce the annular ring below the accepted standard of the fabrication house, try to limit the usage of such affected pads and vias. The more pads and vias on the board that use such annular ring specifications, the more chance there is of a board failing during the fabrication process.

- To have no annular ring would, for one thing, cause poor solder joints, as there would be no copper for solder to flow onto after emerging from the pad/via barrel.

- Standards define a minimum value for the annular ring, but these values can be reduced further. The reason why they are defined at the levels they are, is to guard against drill breakout. This phenomenon is fairly common when dealing with low values for the annular ring. Drill breakout occurs as a result of several manufacturing parameters (e.g. hole location, hole size, film expansion) interacting unfavorably with one another, leading to the hole being drilled in such a position as to cut through the connecting copper track(s).

- It is possible to allow controlled drill breakout, without sacrificing board performance. One method of achieving this is to apply teardrops to required pads and vias. Teardropping (otherwise known as filleting, or tapering) is the process of applying additional land area to the pad/via at the junction with any connecting track(s). This additional area protects the pad-track (or via-track) connection should breakout occur.