Altium Customer Success

Benchmark Unifies Engineering Teams with Altium’s Collaborative Hardware Development Solutions

“For the customers that come to us for Altium usage, there are more options there. They have more collaborative features, and allow us to focus more on the design needs and what the customer is trying to achieve.”

Discover how Benchmark eliminated manual processes, improved cross-team visibility, and accelerated product development with Altium solutions.

- Aligned electrical, mechanical, and software teams in Altium

- Saved time with efficient Harness- and Multiboard Design

- Streamlined ECAD-MCAD collaboration with MCAD CoDesigner

- Improved process visibility with the Part Creation Workflow

Benchmark is a global leader in product design, engineering services, and advanced manufacturing, serving original equipment manufacturers across a wide range of industries—from aerospace and defense to medical technologies and advanced computing. Since its founding in 1979, the company has built a reputation for delivering end-to-end solutions that span the entire product lifecycle, from concept development to volume production and aftermarket support.

With Benchmark's North American engineering teams distributed across different cities and time zones, the company needed to unify design efforts on a shared platform. The company operated three separate engineering groups within North America, each with its own tools, making cross-team collaboration difficult. As projects grew in complexity and required tighter integration, Benchmark began searching for a solution that could bridge geographical gaps and foster real-time collaboration across its engineering ecosystem.

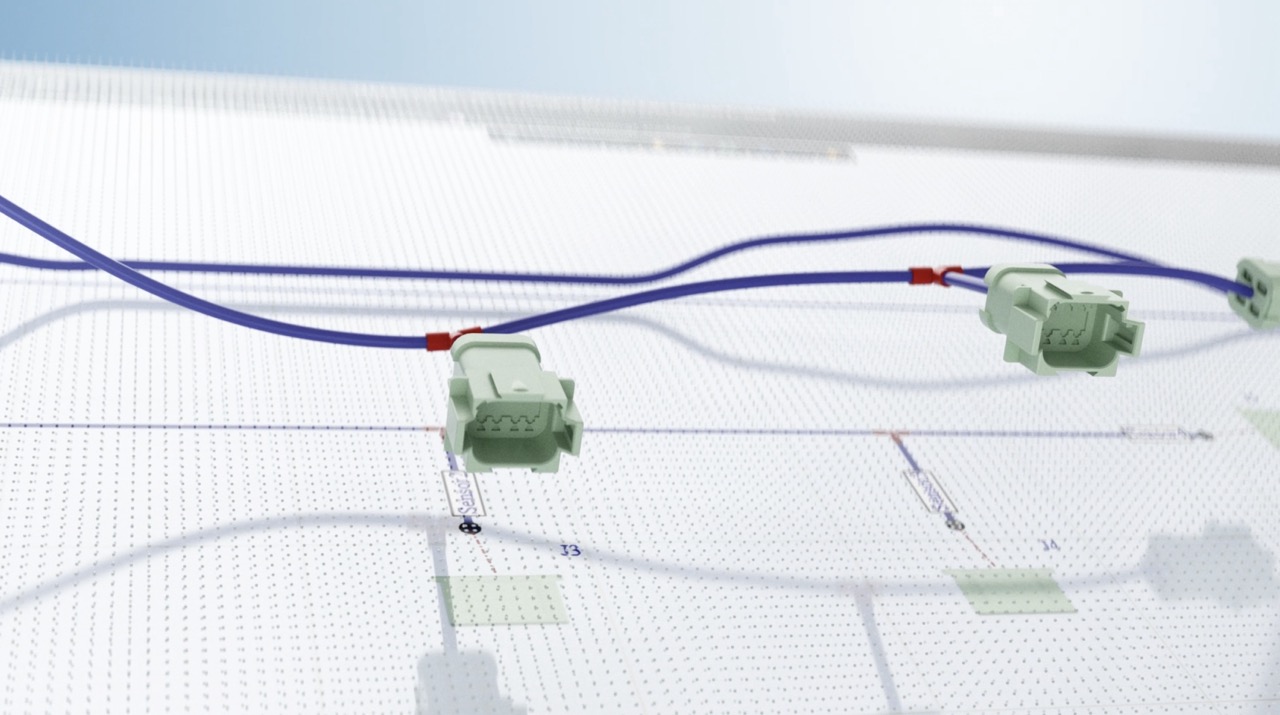

Cable Harness Design and Multiboard Design

“We used [Harness Design] on a pretty big customer project right off the bat. It had saved us a decent amount of time and money to have that tool help us route that complicated cable instead of doing it all by hand.”

Multiboard and Harness Design Across Disciplines

In the past, Benchmark’s engineering teams designed harnesses as part of their larger electronics projects. Limited visibility into changes often led to misalignment between electrical and mechanical efforts. As a result, teams worked out of sync and spent valuable time reconciling updates.

With Harness Design and Multi-board System Design in Altium Develop, Benchmark moved to a unified design process built on a single, cohesive data model. Engineers could access and manipulate detailed data for schematics, layouts, simulations, harnesses, and multi-board designs without manually syncing separate files. This integration enabled true interdisciplinary design, reducing complexity and improving collaboration across disciplines.

When sharing system designs with mechanical engineers, Benchmark leveraged Altium’s ECAD-MCAD CoDesign for seamless synchronization. Using the MCAD Co-Designer panel within Altium designer, electrical engineers could push board outlines, harness layouts, and keep-out zones directly to MCAD, while mechanical engineers could route cables, adjust enclosures, and send updates back to ECAD—all without leaving their preferred environments or manually exchanging files. This bidirectional workflow preserved design integrity and dramatically reduced time spent on file transfers and version tracking, allowing Benchmark to accelerate development and maintain alignment across complex projects.

“As a design engineer, efficiency becomes a key factor for us. Prior to using Altium’s CoDesigner, there would be nothing passed to the mechanical department from the electrical department.”

Streamlining Design Visibility for Software Teams

One of the early obstacles blocking Benchmark’s collaboration meant that its software engineering teams struggled to access the most current design files. Without a centralized system, engineers had to manually check with colleagues to confirm if they were working from the latest version—a process that often involved messaging back and forth, introducing delays and uncertainty. This lack of visibility not only slowed development but also made it difficult for software engineers to identify test pins or leave feedback on designs in a consistent, traceable, and contextual way.

To solve this, Benchmark adopted Altium’s cloud-based collaboration platform, which provided version control built specifically for electronics. With design files rendered directly in a browser, software engineers could view the latest schematics and PCB layouts from any device—no ECAD installation required. This browser-based access allowed engineers to probe designs, identify test pins, and leave comments to clarify functionality or flag issues, all within a shared workspace.

“It took away that barrier of having to message someone and say: do I have the latest schematics? Are you guys working on anything that’s going in there? What if I need to provide feedback? Altium 365 gives me that one place to go to. It’s just one tab away and shows me exactly which line to follow and which test pins to probe. As software guys we don’t have to look that up. We just have to click like we’re used to.”

Structuring Part Creation with Transparent Workflows

As Benchmark worked to unify its engineering teams, another challenge emerged around part creation and BOM management. Each group had its own process for reviewing components and adding new parts to their library, but without a shared system, there was no visibility into which parts were approved, in progress, or still under review. This lack of transparency made it difficult to verify part status during design, leading to delays and causing rework.

To address this, Benchmark turned to Altium’s configurable, diagram-based workflows, tailored to the team’s existing processes. These workflows allowed engineers to assign task ownership, track progress, and monitor part creation status in real time—all within a centralized platform.

“The biggest benefit of having [our processes] directly in Altium is to see if it’s gone through the workflows, you can see if it’s in the review state and ready to be produced, or in the draft state, and it's a nice double check before we build something.”

Accelerating Collaboration and Eliminating Barriers

By adopting Altium’s suite of collaborative design tools, Benchmark successfully unified its geographically dispersed engineering teams and streamlined critical workflows across electrical, mechanical, and software domains. With centralized access to design data, synchronized ECAD-MCAD integration, and configurable part creation workflows, the company eliminated some repeated manual busywork and improved cross-team visibility. These capabilities enabled Benchmark to accelerate development, reduce errors, and maintain alignment across complex projects—ultimately strengthening their ability to deliver custom solutions for highly competitive industries.