Altium Customer Success

HitIQ Leverages Altium to Advance Concussion Monitoring and Management

“Having a collaborative environment for sharing projects with cross-functional teams became much easier and efficient with Altium 365.”

Discover how HitIQ is iterating with speed and flexibility to deliver a groundbreaking concussion management solution to enhance player safety in sports.

Seamlessly created flexible products with Rigid-Flex Design

Accelerated reviews with Altium 365’s Sharing & Web Viewer

Aligned manufacturing requirements with Constraint Manager

Concussions remain one of the most complex and often undetected injuries in sports, with diagnosis typically relying on subjective reporting from athletes or doctors. Each concussion presents differently, with symptoms ranging from memory loss and vomiting to migraines, anxiety, and sensitivity to light and noise. The unpredictable nature of concussions makes early detection and effective management challenging, often leaving athletes vulnerable to long-term neurological damage.

HitIQ is at the forefront of concussion research and prevention, leveraging data-driven solutions to change how sports-related brain injuries are managed. With insights from their instrumented mouthguards, HitIQ empowers teams, leagues, and medical professionals to control training loads, refine policies, and make informed decisions that prioritize player safety at every level of competition.

Innovating Concussion Detection with a Smart Mouthguard

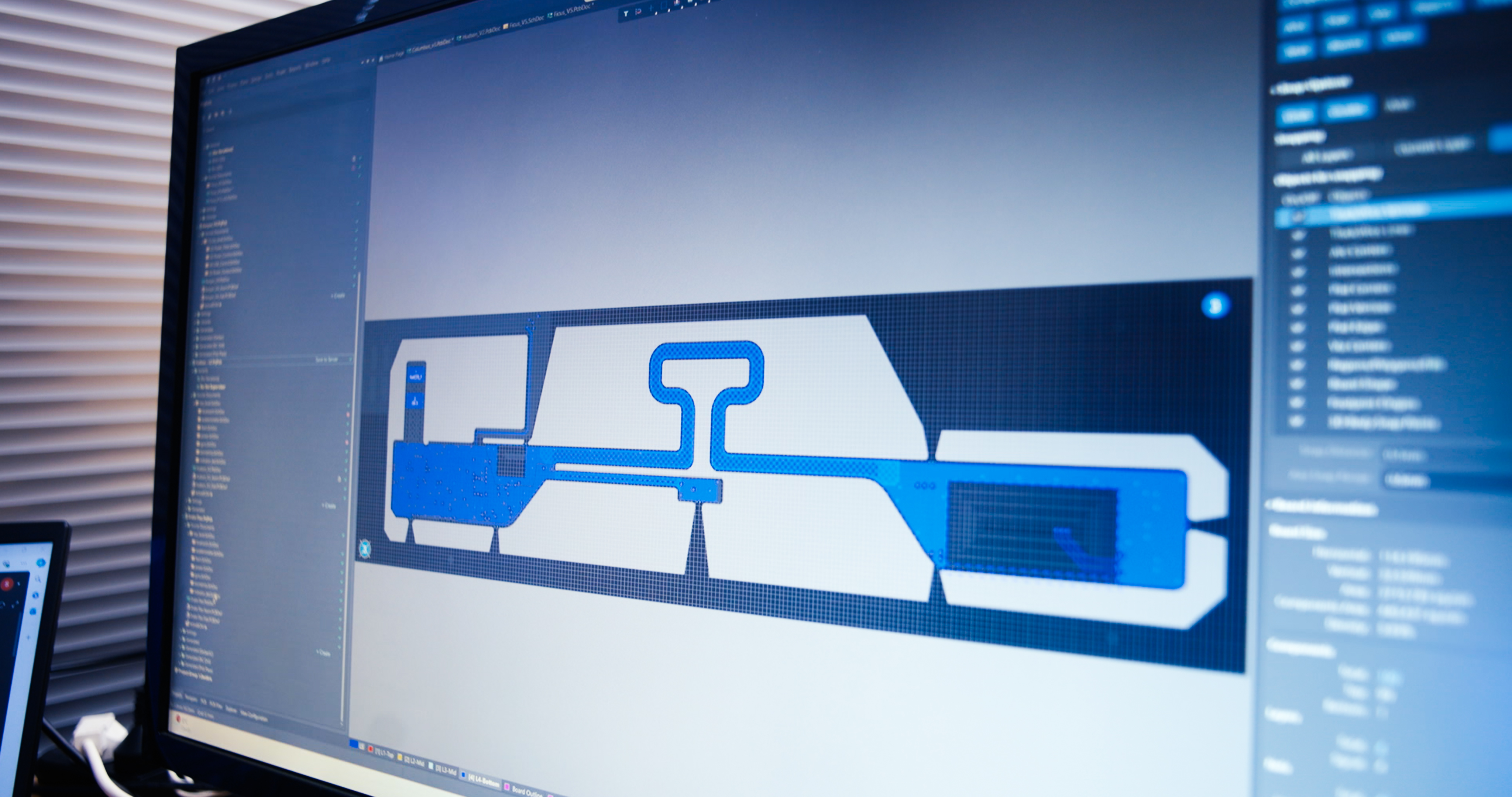

HitIQ worked with Altium to develop their Smart Mouthguard, which is equipped with a flexible PCB embedded with microsensors that measure motion and proximity, capturing data at a rate of 15,000 times per second whenever a head impact occurs.

Despite its cutting-edge technology, the device looks, feels, and functions just like a standard mouthguard, ensuring that athletes can wear it without discomfort or disruption. The system features wireless charging and connects to a smartphone app, delivering rapid insights and notifying the wearer of any potentially dangerous impacts.

Overcoming the Constraints of a Mouthguard Form Factor

One of the biggest challenges HitIQ faced was designing a PCB that could integrate advanced technology while remaining thin, small, and flexible enough to fit within the compact form of a mouthguard. The device required a range of complex components, including an integrated accelerometer and gyroscope for hyper-accurate impact tracking, Bluetooth® 5.0 connectivity for data transmission to the Smart Mouthguard App, and optical sensors for additional monitoring capabilities. The design also needed to incorporate a power subsystem, a battery with a charging system, and an LDO regulator.

Altium Designer’s Rigid-Flex PCB design capabilities allowed the HitIQ team to develop a highly functional, compact, and durable flex PCB within their unified design environment. The team integrated stiffeners, adhesives, and coverlays directly into their PCB designs, ensuring that every component was clearly defined for their manufacturer. The use of 3D visualizations provided a comprehensive view of their flex PCB, allowing for precise adjustments before production.

Integrated Design, Visualized and Controlled

“Having a 3D visualization is really nice. And the integrated version control and release management process that used to be external is really powerful.”

Designing Within Manufacturer Capabilities

To ensure their mouthguard met the highest performance and manufacturing standards, the team needed to create design rules based on their manufacturer’s advanced capabilities. These guidelines would serve as the foundation for a seamless transition from design to production.

Altium Designer’s Constraint Manager enabled the team to define highly detailed design rules, ensuring scalability and precise management of their complex project. Engineers were able to manage constraints across both schematic designs and PCB layouts, promoting design uniformity while minimizing the risk of errors. With an intuitive interface and real-time verification tools, navigating design constraints became more efficient, ensuring every parameter was accurate and aligned with their manufacturer’s specifications.

Designing with Manufacturing in Mind

“From the beginning of the project we could set up design rules in Altium based on our manufacturer’s advanced capabilities and then design based on that. This made us streamline the design quite a bit.”

Creating a Collaborative Environment for Cross-Functional Teams

HitIQ needed a collaborative environment to share projects with cross-functional teams, including mechanical engineers, industrial designers, and firmware engineers. Their development process required rapid prototyping, timely feedback, and seamless updates across various disciplines.

Altium 365’s Web Viewer allowed the team to share real-time project states with team members, manufacturers, and even customers. Collaborators could review and mark up designs directly from a browser, eliminating the need for specialized ECAD software. This was especially beneficial for firmware engineers, who could quickly gain clarity on the function of specific pins from the schematic design.

Altium 365’s Project History provided the team with a complete log of all project commits and releases, offering detailed insights into every iteration. This ensured that changes were well-documented, making it easier to track progress and understand modifications introduced at each stage of development.

Altium 365 Cloud Storage consolidated all of the team’s libraries and design data into one secure Workspace, ensuring that the right team members had access to the right design data at the right time.

One Platform, All Disciplines

“We had to work with a lot of different engineers from other fields like mechanical engineers, industrial designers, and firmware enginers. Altium helped us share projects and get a quick overview of what each pad is doing.”

Advancing Concussion Management with Altium

HitIQ leveraged Altium’s powerful design and collaboration tools to develop their innovative Smart Mouthguard, overcoming complex challenges in PCB design, manufacturing alignment, and cross-functional collaboration. By integrating Altium into their workflow, HitIQ accelerated development, improved accuracy, and delivered a groundbreaking concussion management solution to enhance player safety in sports.