BOM Management

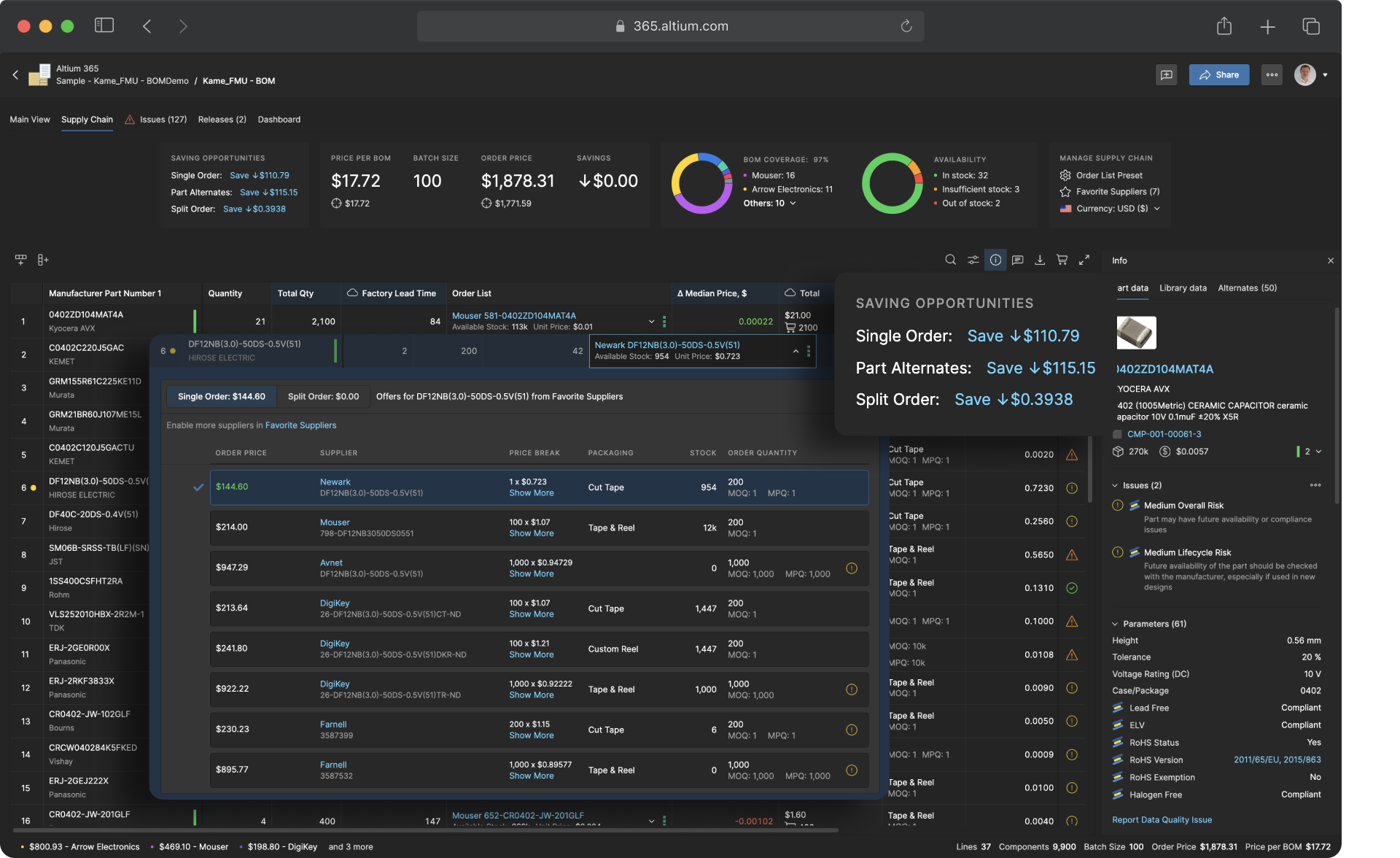

Centralized BOM management with up-to-date component data.

Detect and resolve issues, consolidate across projects, and streamline ordering.

Complete BOMs Faster with Enriched Parts Data

Up-to-date part data accelerates product design. Altium provides engineers and

procurement with current specifications, compliance details, lifecycle status, availability, and pricing—enabling fast, confident decisions and structured collaboration to complete BOMs efficiently.

Proactively Mitigate Supply Chain Risk

Altium enables structured risk management across your team. Real-time analysis delivers early warnings on shortages, price changes, and end-of-life issues—giving everyone the visibility to adapt quickly and prevent costly delays.

Control BOMs with Structure and Simplicity

Combine spreadsheet simplicity with structured version control. Securely share BOMs with stakeholders, track releases across revisions, and apply customizable lifecycle states—maintaining flexibility without sacrificing control.

Centralize Parts for Reuse and Traceability

Centralize your part management in a structured library that drives reusability and full traceability. Create and edit parts from BOMs, adapt component choices on the fly, and track usage across all designs—giving teams complete visibility into part decisions.

Key Capabilities

Valued by Users,

Trusted by Organizations

“Usually, the first prototypes I do need to happen quickly. So we have 48h for boards, during which time I order components. Here is so much thanks to the ActiveBOM and the handling there, it simplifies the work immensely. Then I take these boards and send them to a local lab. They can hand/semi-automatically mount almost anything in 4-8 hours. ‘Yesterday’ this was done using paper and Excel. ‘Today’ we moved to Altium 365 with ActiveBOM. ‘Tomorrow’ I hope we could use the Assembly App where they can tick off anything they have mounted. It is just fabulous.”

“We now have the feature to check which component is in which product, and we can even see with ActiveBOM which components are end-of-life or obsolete. This is a great tool and gives a big, big benefit and also, it's possible for the purchasers that they check now inside Altium 365 which components are used where. And they can even check the availability and end-of-life information.”

Resources

Whitepaper

Building Supply Chain Resilience: Transforming BOM Management for Modern Electronics

Webinar

From PCB Design to Parts Ordering in Minutes with Altium 365 BOM Portal

Blog

How Can I Make BOM Creation and Management Easier with a Cloud Solution?

Contact Us

to Learn More About

Altium Agile

Platform-based solution for electronics product

and systems, delivering control without complexity

Complete this form and our sales team will reach out to answer your questions about Altium Agile Teams or Altium Agile Enterprise.