Supply Chain

Accelerate collaboration between engineering and procurement

with structured BOM management and up-to-date part intelligence.

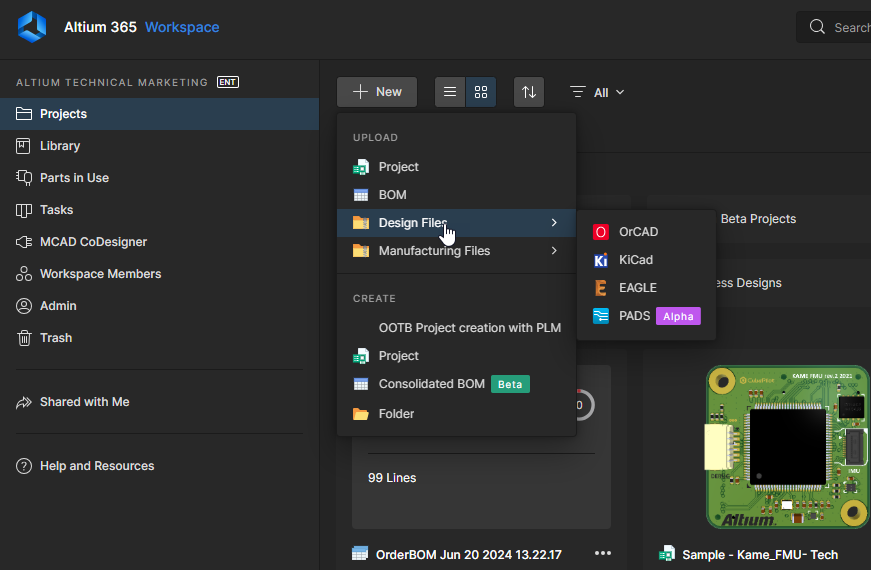

Integrate BOM Management Into Development

Altium enables fast, structured collaboration between purchasing and engineering throughout the development lifecycle. Replace parts efficiently through engineering change orders (ECOs) directly from BOM documents or contextual comments—keeping teams aligned without slowing down.

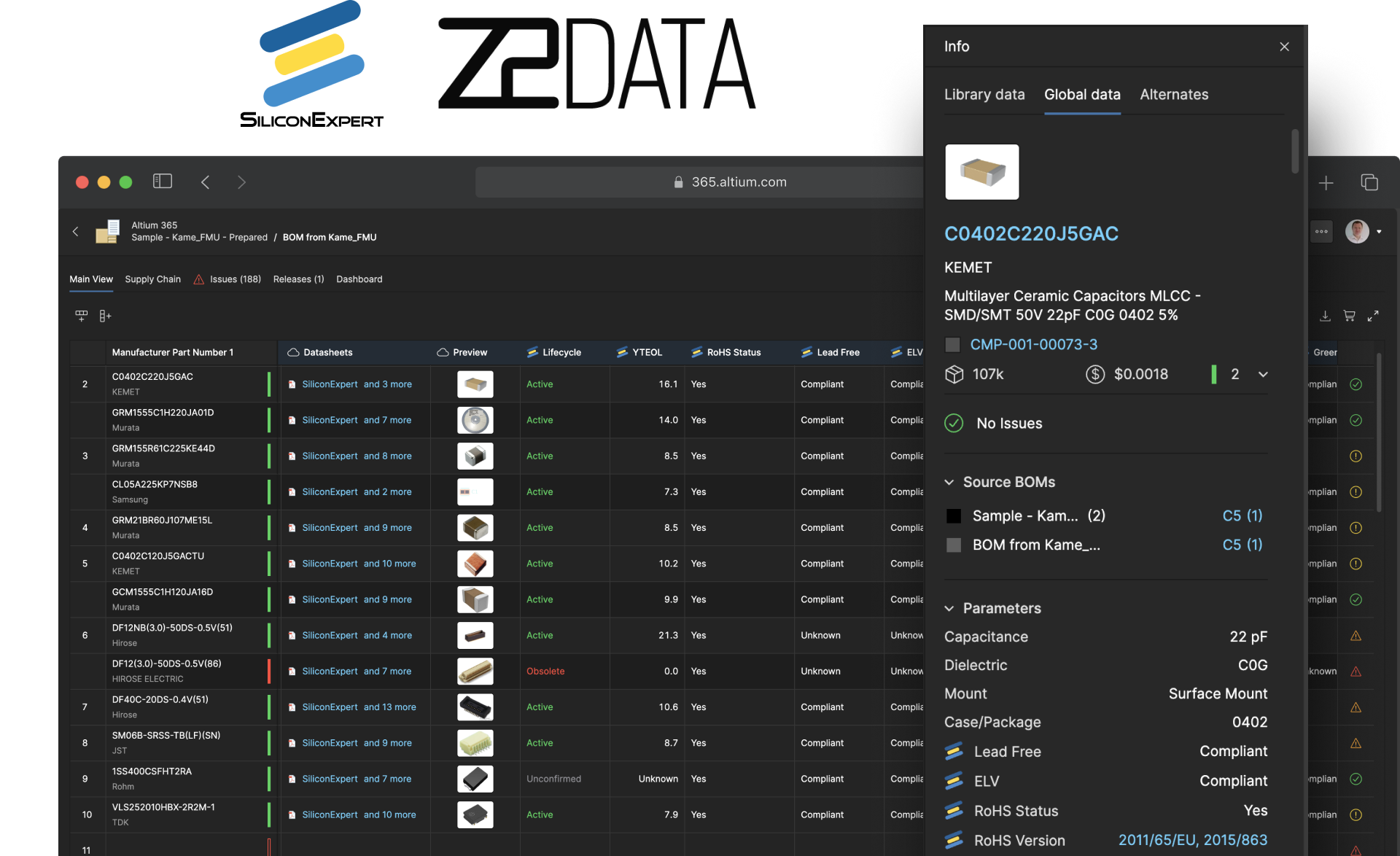

Proactively Control Risk & Cost

Altium automatically enriches BOMs with real-time pricing, availability, lifecycle status, and alternative part options. With integrated data from Octopart, IHS Markit, SiliconExpert, Z2Data, and the sourcing module, your team gains the structured intelligence needed to monitor BOM health and respond to supply chain changes with confidence.

Make Informed Sourcing Decisions at Speed

Altium embeds up-to-date supply chain intelligence directly into your design workflow. When engineering and procurement have shared access to pricing, availability, compliance, and risk data, teams move faster together—adjusting in real time without disconnected tools or manual handoffs.

Key Capabilities

Streamline BOM Management with Data-driven Analysis & Collaboration

Accelerate structured collaboration between engineering and procurement with centralized BOM management. Automatically integrate up-to-date supply chain intelligence for early risk detection—enabling fast, informed decisions across multidisciplinary teams throughout development.

Embed Octopart & IHS Markit Data Into Design Workflows

Eliminate time-consuming external searches with integrated intelligence from Octopart and IHS Markit. Access real-time part specifications, lifecycle status, compliance details, and technical attributes directly in Agile Teams—keeping work moving at speed.

Access Advanced Risk & Lifecycle Intelligence

Strengthen component decisions with advanced supply chain analytics from SiliconExpert and Z2Data. These extensions provide comprehensive risk scoring, years-to-end-of-life (YTEOL) forecasting, manufacturer-verified specifications, and sustainability metrics—extending your visibility into component lifecycle, obsolescence, and compliance risks across all projects.

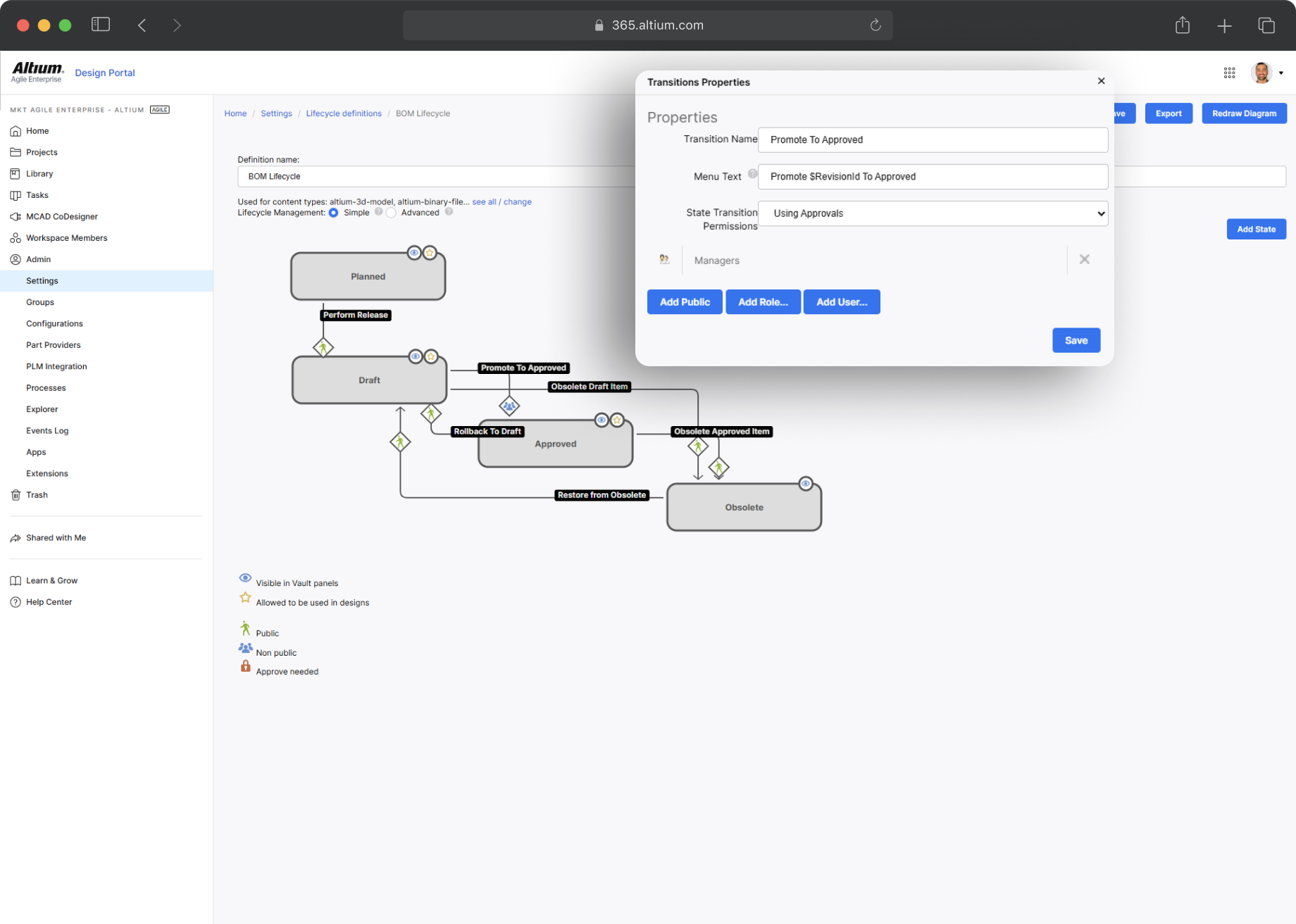

Enable Configurable BOM States & Lifecycle Approvals

Bring structure and governance to BOM management with configurable states and lifecycle approvals. Define active/inactive BOM states, apply lifecycle rules to releases, and streamline approvals across workflows—ensuring compliance and traceability without unnecessary complexity.

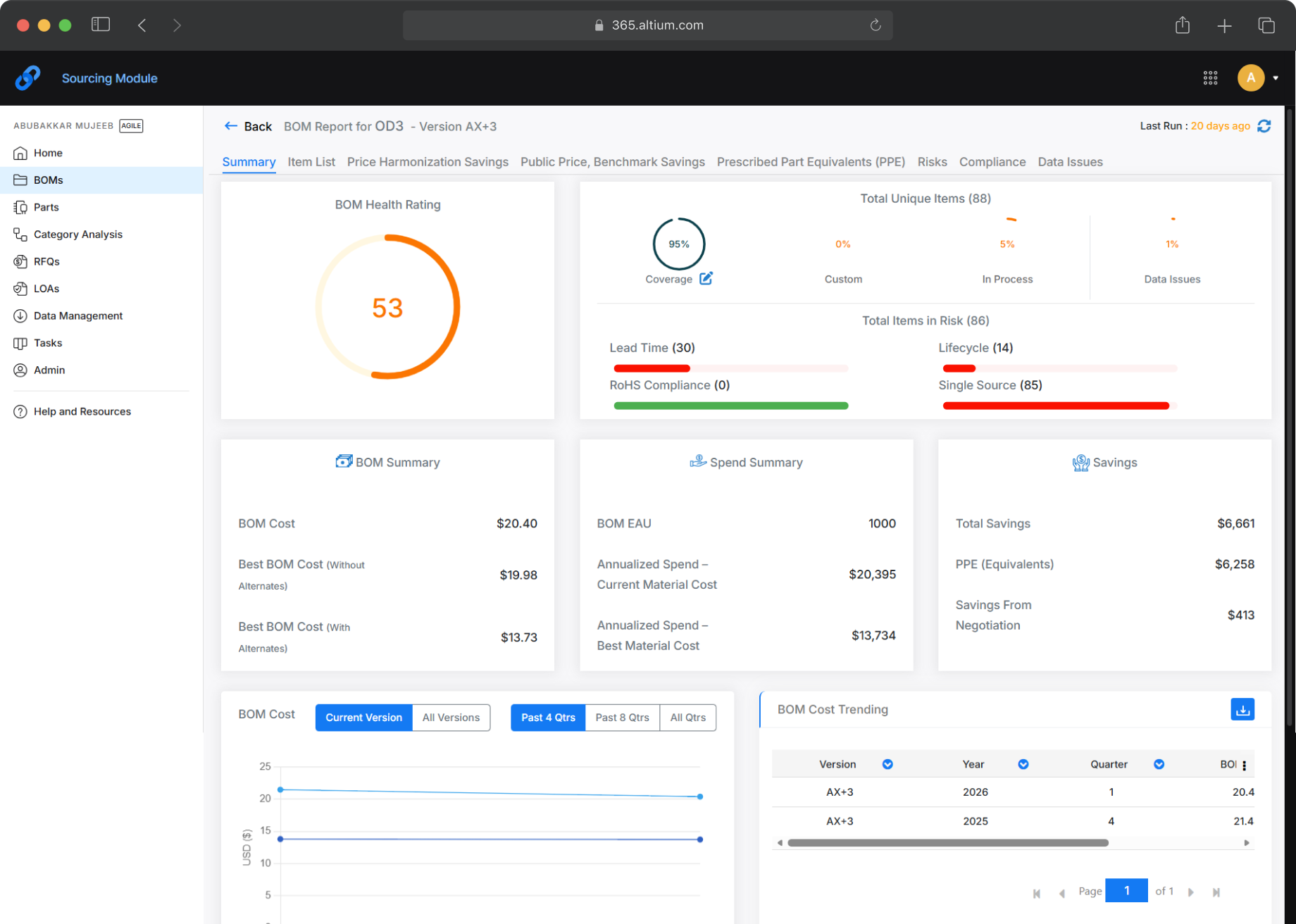

Automate Sourcing & Risk Management with Sourcing Module

Transform sourcing efficiency with integrated workflows delivering real‑time part availability, BOM health ratings, risk rollups, and automated RFQs. Reduce manual effort by up to 98%, gain centralized visibility into supplier risk and compliance, and keep R&D and procurement aligned so designs use affordable, available, and compliant parts.

Valued by Users,

Trusted by Organizations

“Usually, the first prototypes I do need to happen quickly. So we have 48h for boards, during which time I order components. Here is so much thanks to the ActiveBOM and the handling there, it simplifies the work immensely. Then I take these boards and send them to a local lab. They can hand/semi-automatically mount almost anything in 4-8 hours. ‘Yesterday’ this was done using paper and Excel. ‘Today’ we moved to Altium 365 with ActiveBOM. ‘Tomorrow’ I hope we could use the Assembly App where they can tick off anything they have mounted. It is just fabulous.”

“We now have the feature to check which component is in which product, and we can even see with ActiveBOM which components are end-of-life or obsolete. This is a great tool and gives a big, big benefit and also, it's possible for the purchasers that they check now inside Altium 365 which components are used where. And they can even check the availability and end-of-life information.”

Resources

Whitepaper

Building Supply Chain Resilience: Transforming BOM Management for Modern Electronics

Webinar

Component Selection in Altium Designer: Making Data-Driven Decisions with Data Integrations

Blog

How Can I Make BOM Creation and Management Easier with a Cloud Solution?

Contact Us

to Learn More About

Altium Agile

Platform-based solution for electronics product

and systems, delivering control without complexity

Complete this form and our sales team will reach out to answer your questions about Altium Agile Teams or Altium Agile Enterprise.