Military PCB Assembly and Workflow in Altium Designer

No matter which industry or vertical you work in, you’ll need to follow important design, performance, and manufacturability standards. These requirements are more stringent when working with military-grade electronic systems. When you work with design software built on a rules-driven design engine, meeting these important standards becomes much easier.

Altium Designer gives you the power to prepare a compliant PCB design and prepare manufacturer deliverables. The design environment also helps you stay compliant with design and quality standards by giving you full control over all aspects of your design and supply chain. Stay compliant while designing high-quality circuit boards with Altium Designer.

ALTIUM DESIGNER

A fully integrated PCB design suite that guides you from design to fabrication.

As a defense contractor, you need to be sure your next electronic system will be compliant with applicable design, manufacturing, and quality standards. You also need to be sure you’re only sourcing from compliant sources to ensure you don’t break important procurement regulations. PCBs for military applications have their own set of design and manufacturing standards that must be met in order to ensure reliability. This is one area where lives are literally on the line, and your PCBs must be responsive and reliable.

Only Altium Designer integrates your supply chain management, manufacturer deliverables, and design tools within a single design platform. A PCB design workflow for military systems requires specifying appropriate design standards for your boards. You also need to track and source solely from compliant suppliers. These tasks and many more are easy when you use the set of integrated design features in Altium Designer.

PCB Design Workflow for Military Systems

Circuit board designs for military systems need to balance high reliability with regulatory compliance. So how can you design your PCBs to meet these critical standards and ensure reliability? Your design software can play a critical role in ensuring reliability. While all PCBs must be rugged and perform in a range of conditions, PCBs designed for military systems should go above and beyond the rigors of any civilian application.

Military systems with PCBs will see longer periods of use, extreme temperatures or climates, higher electrical demand, and mechanical stresses that would ruin other systems. Your PCB design software needs to give you the ability to satisfy these unique operating demands. If you’re using rules-driven design software to create your PCB for a military system, you can rest assured that your design will meet critical design specifications. Altium Designer is the only rules-driven design platform that helps you create products for the mil-aero market and create a PCB design workflow for military systems design.

The right software package gives you everything you need for military and aerospace PCB design.

What Does Every Military PCB Design Workflow Need?

To have a successful military PCB design workflow you need the same things in place that are important to any design; PCB design software that you can rely on and the training and preparation needed to get the job done. Your PCB design tools must be capable of handling everything from the components you select to final output files. Your tools must be easy to learn and easy to work with. Your PCB design tools shouldn’t slow your process down, but instead, you should be able to efficiently work within the schematic and PCB editor to create the design.

Altium Designer includes features to help you source components from ITAR compliant electronics distributors or specify your own authorized vendors for components. If you’re working with specific vendors that supply components for military systems, you can define these vendors in Altium Designer, giving you full control over your components supply chain. No other PCB design software platform offers this level of flexibility while helping you stay compliant.

- Military applications often require specialized components and layouts that meet specific design standards. Your design software should help you define mil-aero PCB design requirements as design rules to help catch errors and quickly correct them.

- Your PCB design software should automatically generate documentation for all aspects of your device quickly and easily. This ensures your fabricator can produce your new product at scale while complying with critical design standards.

Learn more about the documentation your fabricator requires.

- When you have visibility into the PCB supply chain, you can source components from ITAR compliant manufacturers and other companies that are designated defense suppliers.

Learn more about real-time supply chain updates to help source from compliant components suppliers.

Sourcing and management components in Altium Designer.

Standards on Military PCB Manufacturers

Manufacturers themselves must meet important quality requirements for products they produce, and these standards determine the capabilities military PCB manufacturers must maintain in order to remain compliant. Designers need to balance meeting manufacturing requirements (for example, ISO 9001 and AS9100) with performance and manufacturability requirements during the design phase. You’ll need to follow MIL-PRF, ISO, or IPC standards, or you’ll need to incorporate some mix of all three standard sets when preparing your circuit board design.

US Military Manufacturing and PCB Assembly Standards

Compared to commercial components, where acceptable tolerances range from 5% to 10%, components in military PCBs have tighter tolerances of 1% to 2%. All PCBs for military and aerospace systems should be manufactured according to MIL-PRF-50884, MIL-PRF-31032, and MIL-PRF-55110 standards.

In addition to the above manufacturing requirements, the MIL-PRF-31032 set of standards is by far the most stringent placed on PCBs. Materials, layout, manufacturing, and many other aspects of PCB design are regulated under these standards. MIL-PRF-31032 goes beyond the IPC 6012 3A standards, particularly when assessing PCB manufacturer capabilities.

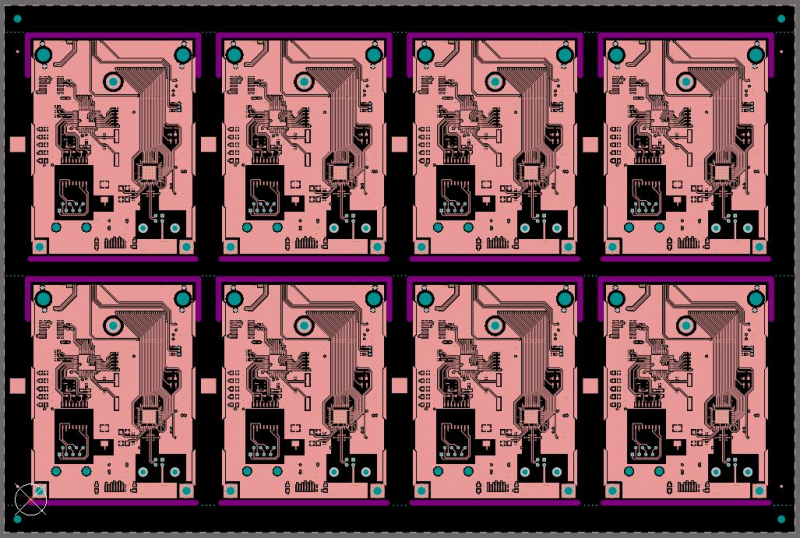

Prepare your boards for PCB fabrication with panelization in Altium Designer.

Other requirements for PCB assembly include clear markings to differentiate high and low-frequency components, the use of heat dissipating or heat resistance materials, proper EMI shielding and isolation around sensitive components, and routing constraints on traces with bends. For PCB assembly, boards must be manufactured to the highest levels of quality and reliability. Even press-fit components will need to be soldered in order to provide exceptional mechanical strength in harsh environments.

These specifications are exacting for many systems, but they are intended to ensure your board will remain reliable. Failing to meet these important standards might cause your board to fail in-field testing, causing your product to be rejected. If you’re a manufacturer, these standards are critical to ensuring finished products can meet military design and reliability standards. Taking account of all these critical design aspects requires PCB software with adaptable tools and customizable design rules.

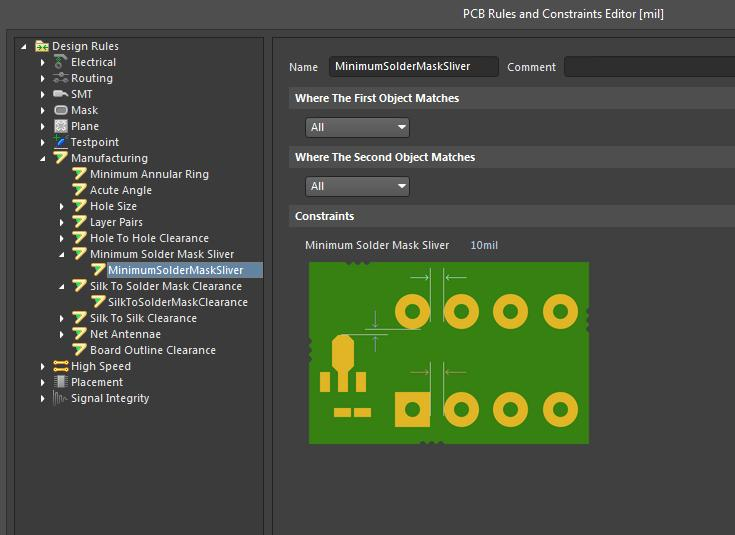

- Your military PCB manufacturing needs will force you to adopt stringent military design standards within your design rules, including manufacturing and PCB assembly tolerances.

See how you can incorporate military standards as PCB design rules for advanced products.

- MIL-STD standards place strict requirements on PCB assembly tolerances and component rating tolerances. You can set these tolerances as design rules to help ensure your board passes inspections and field tests.

Learn more about EMC military PCB assembly tolerances in your design software.

- IPC-6012A standards are meant to ensure reliability in your military systems. When you need to stay compliant and reliable, you can define these requirements as design rules in your printed circuit design software.

Defining design rules in Altium Designer

Designing and Manufacturing Your Military-Grade PCB with Altium Designer

Given these stringent design and compliance requirements, how can you remain sure your boards meet critical military PCB assembly standards? Your PCB design software should take data directly from your layout and check it against the important standards you define as design rules. Your production and assembly planning tools should also use this data to help you create a compliant documentation package for PCB fabrication.

The best design, validation, and deliverable generation tools take your design data and help you quickly move to production. Meanwhile, automated design rules checks and documentation tools should help you stay compliant with military design, PCB manufacturing, and PCB assembly standards. When you need a PCB design suite with a complete set of tools for advanced defense products, use Altium Designer.

Altium Designer Has the Only Unified Design Model

The unified design environment in Altium Designer makes it easy to integrate your sourcing information with your bill of materials, allowing you to find and replace components, accurately estimate your production costs, and manage the full lifecycle of your next device. You won’t have to export design data between programs or write up critical documentation by hand. Your deliverable generation tools read directly from your design data in a single program, ensuring your deliverables are complete and accurate.

- Altium Designer provides the only rules-driven printed circuit design interface to help ensure your new product complies with important military standards.

- When designing your next circuit board for a military and aerospace system, you need a complete set of design tools in a single program.

Learn more about the complete set of circuit board design tools in Altium Designer.

- 3D ECAD/MCAD tools in your PCB design software let you incorporate your enclosure in your new design, giving you a complete solution for creating electronics.

Native 3D placement of surface mount components in Altium Designer

Working in a rules-driven design environment is the easiest way to ensure you’re designing design to important military and aerospace standards. Design more reliable, more advanced products and take them to PCB fabrication quickly with Altium Designer.

Altium Designer on Altium 365 delivers an unprecedented amount of integration to the electronics industry until now relegated to the world of software development, allowing designers to work from home and reach unprecedented levels of efficiency.

We have only scratched the surface of what is possible to do with Altium Designer on Altium 365. You can check the product page for a more in-depth feature description or one of the On-Demand Webinars.