将鼠标悬停在图标上可查看该器件状态摘要。或者,启用显示详细的 BOM Status 列以显示详细信息。可通过 ActiveBOM Properties 面板(包含便捷的搜索框)启用该列,或在 BOM 条目列表的列标题区域右键,然后选择 Select Columns 命令来启用。

将鼠标悬停在图标上可查看该器件状态摘要。或者,启用显示详细的 BOM Status 列以显示详细信息。可通过 ActiveBOM Properties 面板(包含便捷的搜索框)启用该列,或在 BOM 条目列表的列标题区域右键,然后选择 Select Columns 命令来启用。

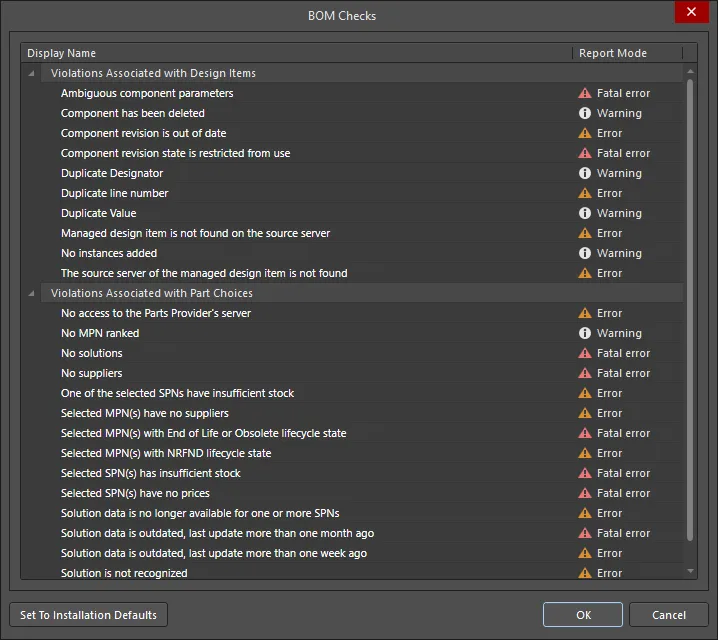

配置 BOM 检查

BOM 条目会自动检查以下内容:

-

Violations associated with Design Items – 这包括一些测试,例如器件的 BOM 参数与库参数不匹配(参数不明确),以及重复的位号。

-

Violations associated with Part Choices – 这包括一些测试,例如未排名的 MPN(仅系统分配排名)、没有供应商,或未达到目标价格。

每个 BOM 检查的严重级别(报告模式)在 BOM Checks 对话框中配置。点击 Properties 面板中“检测到的违规”列表下方的  按钮以打开该对话框。

按钮以打开该对话框。

要实质上禁用某个特定检查,请将其 Report Mode 设置为 No Report。

BOM Checks 对话框用于为每个自动 BOM 检查配置报告模式。

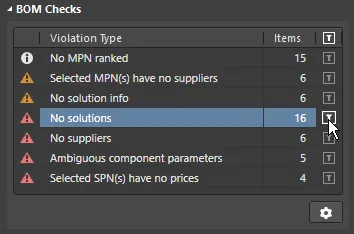

按 BOM 状态筛选 BOM 条目列表

Properties 面板会显示当前 BomDoc 中检测到的 BOM 检查违规列表。点击筛选图标(如下所示)可筛选主 BOM 条目列表,使其仅显示未通过该 BOM 检查的 BOM 条目。请注意,一个 BOM 条目可能会未通过多个 BOM 检查。

点击以筛除所有 BOM 条目,仅保留未通过该 BOM 检查的条目。点击齿轮图标以配置 BOM 检查。

使用筛选功能可快速定位所有未通过特定 BOM 检查的 BOM 条目。

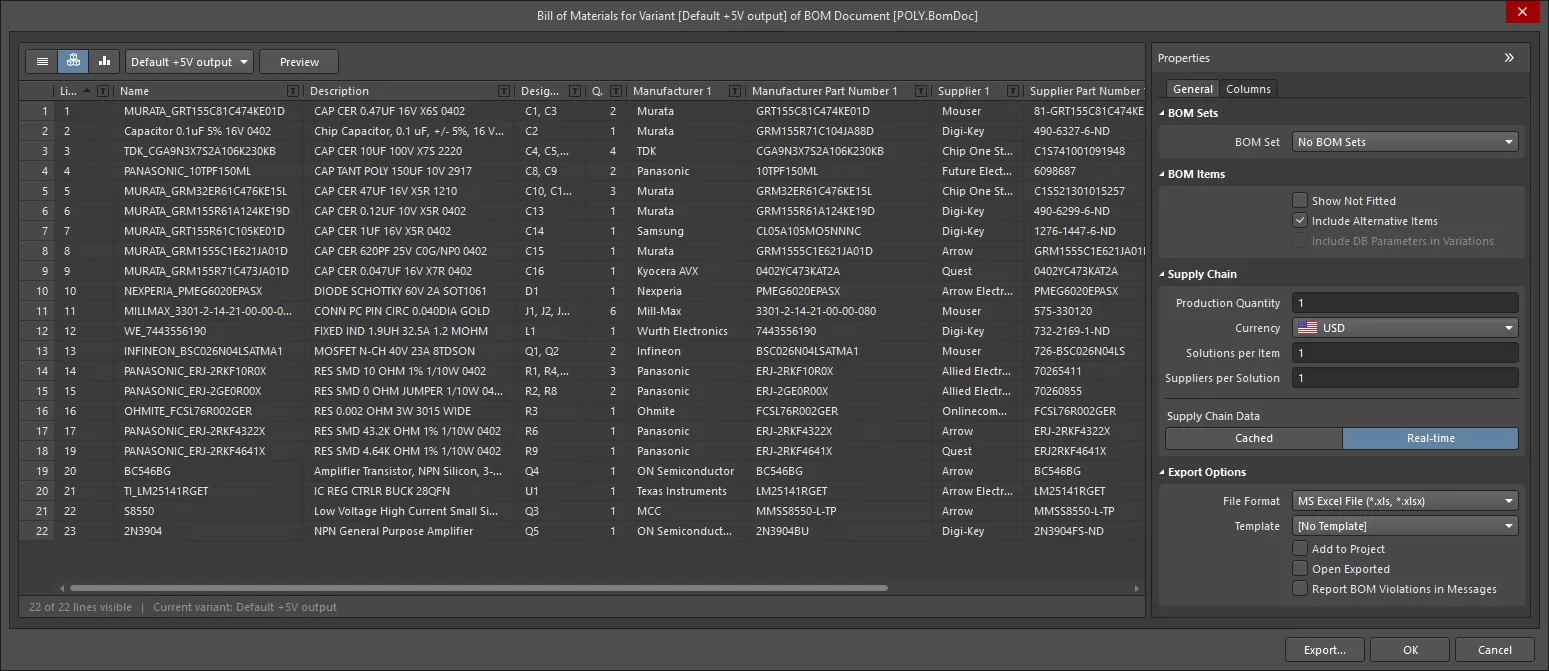

生成 BOM

可直接从 ActiveBOM 编辑器生成 BOM。选择 Reports » Bill of Materials 命令以打开 Report Manager 对话框并生成 BOM。

Report Manager 会以最终输出的形式呈现 BOM 数据。在 ActiveBOM 中,它用于配置输出格式并选择模板。

Report Manager 是标准的 BOM 输出设置对话框,与在原理图或 PCB 编辑器的 Report 菜单中选择 Bill of Materials 时打开的对话框相同,或在 OutputJob 中配置 BOM 时也会打开该对话框。

-

Report Manager 与 ActiveBOM 界面共享许多功能,从而简化 BOM 配置过程。

-

如果项目中存在 ActiveBOM 文档(BomDoc),则其中定义的布局设置会自动应用到 Report Manager 中。

-

在 ActiveBOM 文档中定义的 BOM Sets 可用,可轻松在不同 BOM 布局之间切换。

-

可生成 Excel 格式文件,而无需安装 Microsoft Excel®(选择 Microsoft Excel File (*.xls, *.xlsx 选项)。

要了解更多关于配置 Report Manager 的信息,请参阅页面 BOM Configuration in the Report Manager。

将设计数据映射到 BOM 中

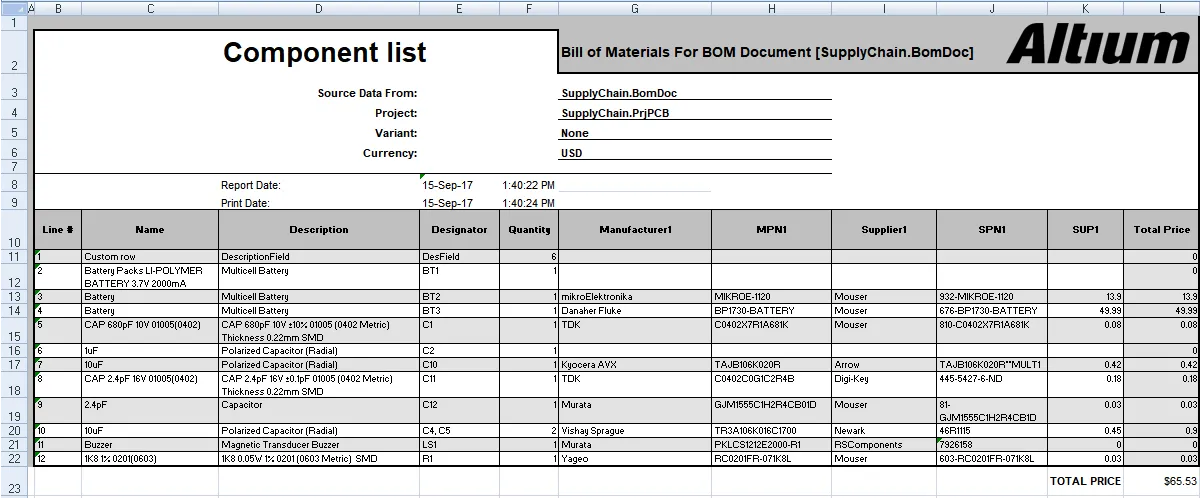

通过在用于创建 BOM 的 Excel 模板中包含 Field 和 Column 声明,可将板级设计流程中的设计数据传递到 Excel Bill Of Materials 中。

-

Fields - 字段声明用于将系统、文档和项目参数传递到 BOM 中,例如文件名、数量、币种等,这些内容通常只需在 BOM 中显示一次。字段声明会被传入的值替换,如下图所示。

-

Columns - 列声明用于传递会出现在所有 BOM 条目中的信息,例如:位号、描述、用户自定义参数等。也可以包括行号、PCB 位置数据,以及在 BomDoc 中输入的自定义列数据。列声明会被 ColumnName 字符串替换,其下方每一行会填充对应 BOM 条目的该列值,如下图所示。

通过在 Excel 模板中定义,将设计数据映射到 Excel 电子表格中。

要了解更多信息,请参阅 BOM Configuration in the Report Manager 页面中的 Mapping Design Data into the BOM 章节。

将当前 BOM 与较早版本进行比较

在不同设计发布版本之间更换元件并不少见。为确保流程正确完成,许多设计人员喜欢将当前项目的 BOM 与项目先前版本的 BOM 进行比较。如果该项目是 Workspace 项目并包含 ActiveBOM BOM 文档(*.BomDoc),则可使用 BOM Compare 功能来完成此操作。

BOM Compare 报告会显示当前设计与所选已发布旧版本之间的变更内容。可通过以下方式配置并生成报告:

-

在 ActiveBOM BomDoc 中,点击 Reports » BOM Compare 以打开 Report Manager dialog 的 Bom Compare 版本。按需配置报告,然后点击 Export。

-

在原理图编辑器中,点击 Reports » BOM Compare 以打开 Report Manager dialog 的 Bom Compare 版本。按需配置报告,然后点击 Export。

-

在 PCB 编辑器中,点击 Reports » Project Reports » BOM Compare 以打开 Report Manager dialog 的 Bom Compare 版本。按需配置报告,然后点击 Export。

-

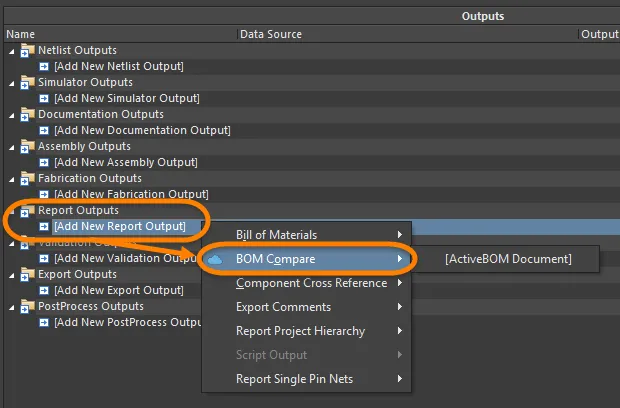

在 outjob 中,在 Report Outputs 条目下右键点击 [Add New Report Output] ,然后选择 BOM Compare。要配置报告,请在新添加的 BOM Compare 条目上右键并选择 Configure ,以打开 Report Manager dialog 的 Bom Compare 版本。按需配置报告,然后点击 Export。你也可以选择所需的输出容器后生成报告。

可从多个位置执行 BOM Compare,包括 OutputJob。

BOM Compare 会检测当前设计中的元件条目与所选已发布版本之间的差异(delta),并生成仅列出不同元件条目的报告。它会比较所有参数,仅排除价格、库存水平等动态参数。

你可以在 Report Manager 中配置 BOM Compare 报告中可见的列。

BOM 对比会在 Report Manager 中打开,可按需配置列。

Options and Controls of the BOM Compare Report Dialog

视图模式

有三种视图模式可用于显示条目列表。使用网格上方的按钮选择所需模式:

-

Flat view - 点击以为每个元件显示一行。

Flat view - 点击以为每个元件显示一行。

-

Base view - 点击以为项目中每种唯一元件显示一行。Designator 列会列出该类型所有元件的位号。

Base view - 点击以为项目中每种唯一元件显示一行。Designator 列会列出该类型所有元件的位号。

-

Consolidated view - 当项目包含变体时点击使用,以显示所有变体的 Consolidated BOM。

Consolidated view - 当项目包含变体时点击使用,以显示所有变体的 Consolidated BOM。

Base 和 Consolidated 视图的默认分组方式为:对受管元件按元件 ItemID 分组,对非受管元件按 Library Reference 分组。在 BomDoc 中,可在

Component Grouping 对话框中启用额外或替代参数来细化分组;该对话框可从 BomDoc 的

Properties 面板访问。如果

Report Manager 使用 BomDoc 作为来源,则可以为所有变体生成单一 BOM。这称为 Consolidated BOM;要显示它,请将

View Mode 设置为

Consolidated View。

变体

如果项目中定义了变体,它们会列在下拉列表中;选择所需变体。如果启用了 Consolidated 视图,则该控件会被禁用。

预览

点击  可根据 Properties 面板中 File Format 和 Template 选项的当前设置,将报告导出并在与该文件类型关联的外部应用程序中打开。

可根据 Properties 面板中 File Format 和 Template 选项的当前设置,将报告导出并在与该文件类型关联的外部应用程序中打开。

General 选项卡

主区域列出所有元件。

修订版本

使用下拉列表选择所需的修订状态。所选修订状态会反映在网格中。

Bom Items

-

Show Not Fitted - 启用此选项可在网格中显示 Not Fitted 条目。

为所选变体定义为 Not Fitted 的元件将被移除,除非启用了 Show Not Fitted 选项。若要在 BOM 中保留 Not Fitted 的元件并明确将其标记为 Not Fitted,请启用 Show Not Fitted 选项,并在该对话框的 Columns 选项卡中启用 Fitted 列。对于每个元件,此列中的条目会反映该元件针对所选变体是 Fitted 还是 Not Fitted。对于在所选变体中为 Not Fitted 的元件,在 Quantity 列中输入的值为零 (0)。

-

Include Alternative Items - 启用此选项以在 BOM 中包含替代物料。Alternative Item 会显示在原始器件下方的新一行中。

-

Include DB Parameters in Variations - 如果存在通过 DbLink/DbLib/SVNDbLib 文件放置的数据库元件,并且这些元件在设计变体中发生了变化,则启用此选项可在所选变体更改时更新数据库参数。

导出选项

-

File Format - 从下拉列表中选择一种格式。支持以下文件格式:

-

CSV(逗号分隔)(*.csv)

-

制表符分隔文本 (*.txt)

-

MS-Excel (*.xls, *.xlsx *.xlsm) (使用 Microsoft Excel)

-

通用 XLS (*.xls, *.xlsx, *.xlsm) (使用内置的 XLS 格式文件生成器,因此无需安装 Microsoft Excel 也可生成该格式)

-

便携式文档格式 (*.pdf)

-

网页 (*.htm, *.html)

-

XML 电子表格 (*.xml)

-

Template - 选择文件格式后,使用下拉列表选择用于导出的模板格式。选项包括基于文件的模板和受管模板。

-

Add to Project - 启用后,在生成报告后将其添加到项目中。

-

Open Exported - 启用后,在导出文件保存完成后打开相应的软件应用程序,例如 Microsoft Excel。

列选项卡

此选项卡用于配置每个 BOM Item 显示哪些参数,以及这些参数可用的数据源。

-

Columns - ActiveBOM 可用的所有器件信息来源列表。可通过单击任意标题字段对 Columns 区域进行排序,包括 Visibility (

) 和 Source 列。

) 和 Source 列。

-

Visibility - 单击左侧列中的可见性图标,以控制该列在主 BOM Items 网格中的可见性。

-

Source - 显示一个图标,用于指示该参数来源于何处:

-

- 来源于原理图。

- 来源于原理图。

-

- 来源于 BOM。

- 来源于 BOM。

-

- 来源于服务器。

- 来源于服务器。

-

ame - 显示属性/参数名称,该名称在源文档中定义,或为用户创建的 BomDoc 列所输入的名称。

-

Alias - 如有需要,可在源 BomDoc 中定义别名以重命名某一列。

其他控件

-

Export - 单击以生成报告。将打开一个标准 Windows 对话框,你可以在其中为报告命名。

右键菜单

-

Preview - 单击以基于 File Format 和 Template 选项的当前设置生成报告预览。

-

Copy - 用于复制全部或选定数据。

-

Copy With Header - 用于将所选数据复制并粘贴到外部电子表格(如 Microsoft Excel)中。

-

Best Fit - 将 Name 和 Descriptions 列的内容合并,使其紧密排列,列与列之间不留多余空隙。

-

Best Fit All Columns - 将所有列的内容合并,使其紧密排列,列与列之间不留多余空隙。

-

Restore from <.BomDoc> - 用于从指定的 BomDoc 还原。

-

Change PCB Document - 用于切换到另一个 PCB 文档。

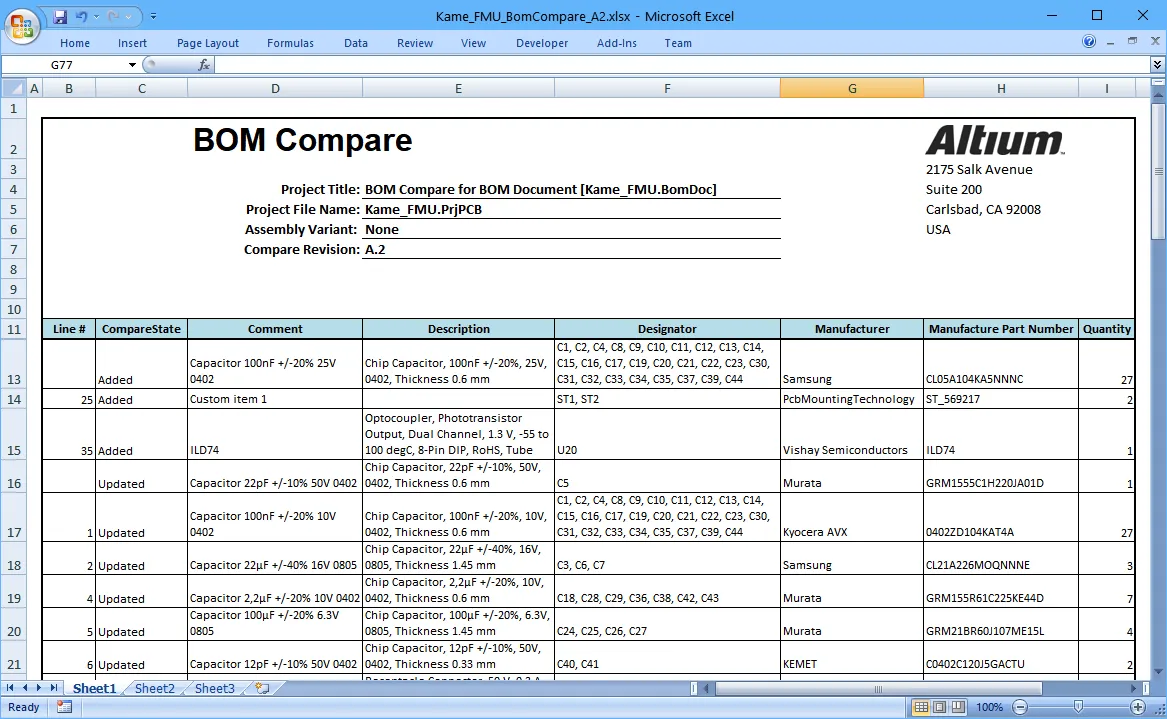

Report Manager 对话框中默认显示的列包括:

-

CompareState

-

行号

-

名称

-

描述

-

位号

-

制造商料号 1

-

数量

应用了 Excel 模板的 BOM Comparison 报告示例。

了解更多关于 为 BOM 或 BOM Compare 数据配置 Excel 模板 的信息。