PCB Editor Preferences

Altium Essentials: PCB Introduction

This content is part of the official Altium Professional Training Program. For full courses, materials and certification, visit Altium Training.

The pages in the PCB Editor category of the Preferences dialog provide access to preferences relating to features and functionality with the PCB Editor.

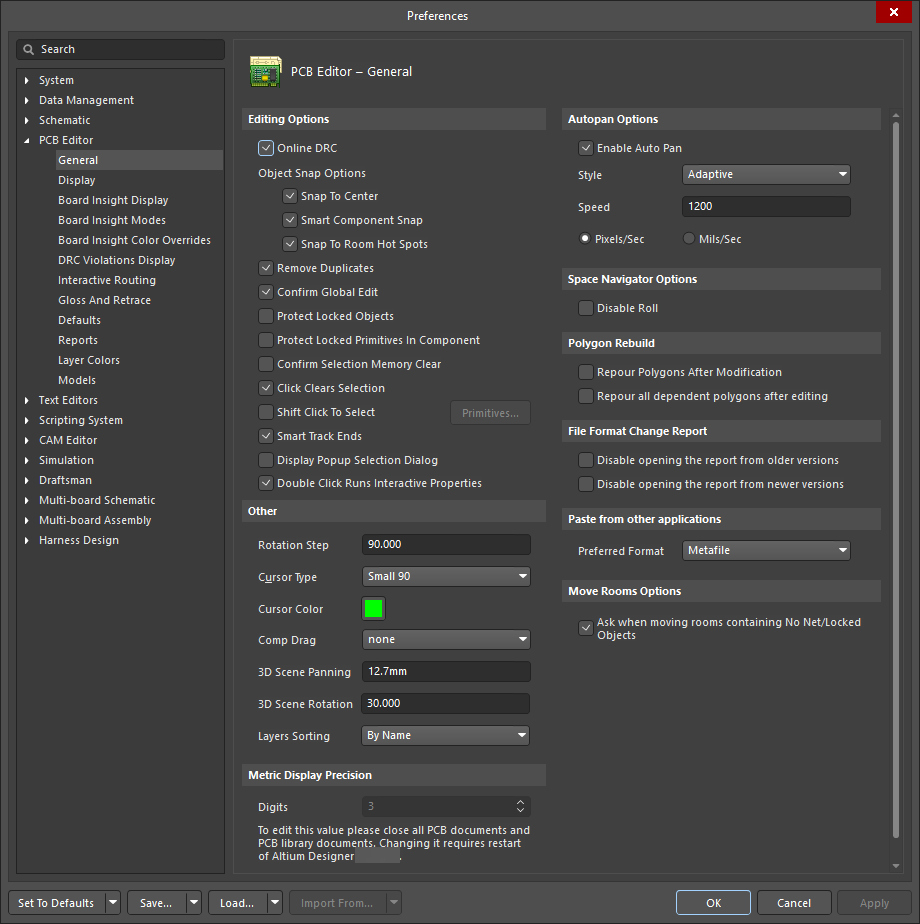

General

The PCB Editor – General page of the Preferences dialog provides numerous controls relating to the general settings of the PCB editor within the PCB design space.

The PCB Editor – General page of the Preferences dialog

Editing Options

- Online DRC – enable to have software monitor all PCB design rules interactively as you work and immediately highlight any rule violations. If this option is disabled, design rule violations will not be highlighted as you work. Violations will only be highlighted when you manually run a Design Rule Check.

-

Object Snap Options

-

Snap To Center – enable to have the cursor jump automatically to a defined reference point on the object when you select it and be "held" by that point as you reposition it. When moving a free pad or via, the cursor will snap to the center of the object. When moving a component, the cursor snaps to the reference point of the component. When moving a track segment, the cursor snaps to the vertex point. If this option is disabled, objects will be "held" by the point at which you click on them.

-

Smart Component Snap – enable so that when you click to select a component, the crosshair cursor appears on the nearest pad of this associated component with respect to the cursor. Disable this option so that the cross-hair cursor always appears on the pad reference point of this component when it is clicked.

- Snap to Room Hot Spots – enable to have the cursor jump to the room hot spots.

-

- Remove Duplicates – enable to check for and remove duplicate primitives when the system is preparing data for output. Enable this option when outputting to a vector device, such as a pen plotter or a vector photo-plotter.

- Confirm Global Edit – enable to have a confirmation dialog open before committing a global editing action, including stating the number of objects that will be affected by the action. Using the confirmation dialog, you can cancel the global edit if necessary. If this option is disabled, global editing changes will be made as soon as you click the OK button in a global editing dialog.

- Protect Locked Objects – enable to ignore any selected locked objects if they are part of a selection that is being moved.

- Protect Locked Primitives In Component - enable to prevent modification of component primitives.

- Confirm Selection Memory Clear – enable this option and a confirmation dialog will pop up confirming that you want to clear the selection memory.

- Click Clears Selection – enable this option to clear the current selection by clicking the left button of the mouse.

- Shift Click To Select – enable to force using the Shift key to select specific primitives as specified by the Primitives list. Click the Primitives button to access the list. Disable this option to select a primitive normally.

- Smart Track Ends – smart track ends will recalculate the nets so that they come from the track end rather than the shortest distance.

-

Display popup selection dialog – enable to use the Popup Selection dialog in the PCB editor when selecting co-located objects. The Popup Selection dialog helps you more easily select an object located in a 'stack' of overlapping objects (typically across different layers).

-

Double Click Runs Interactive Properties – enable this option to either open the Properties panel when editing placed objects using double click, or disable it to open the modal dialog when editing placed objects using double click.

Other

- Rotation Step – shows the amount of rotation, in degrees, applied to objects floating on the cursor when the Spacebar is pressed. Edit this field to change the angle (default is 90°). The minimum angular resolution is 0.001°. Pressing the Spacebar when an object is floating on the cursor rotates the object by the set number of degrees in a counterclockwise direction. Hold the Shift key while pressing the Spacebar to rotate in a clockwise direction.

-

Cursor Type – define the shape of the "action" cursor here. This cursor is displayed whenever you perform any editing action (such as placing or moving an object). Click to view and select a cursor type from the list. Available cursors are:

-

Small 90– small cross-hair cursor angled at 90° (e.g., "+"). This is the default. -

Large 90– cursor consists of intersecting horizontal and vertical lines spanning the width of the screen. -

Small 45– same asSmall 90except that the cross-hair lines are at 45° (e.g., "X").

-

- Cursor Color – click to access Choose Color dialog from where you can select a color of the crosshair cursor to be used.

-

Comp Drag - shows how connected tracks are handled when you drag a component. To drag a component, select Edit » Move » Drag from the main menus and then click on the component you wish to drag. Click to view and select an option from the list. Available options are:

-

None– when you drag a component, only the component moves. Any attached tracks will be disconnected and left in place. -

Connected Tracks– when you drag a component, any connected tracks will remain attached to the component.

-

-

3D Scene Rotation – shows the amount of rotation, in degrees, applied to 3D view controls. The 3D Scene Rotation angle is set to

30°by default. Click to edit. -

3D Panning Rotation – shows the amount of the panning, in millimeters, applied to 3D panning controls. The 3D Panning distance step is set to

500mils(12.7mm) by default. Click to edit. - Layer Sorting – use the drop-down menu to select if component layer pairs and mechanical layers should be sorted in the View Configuration panel By Name (default) or By Number (Legacy).

Metric Display Precision

Digits – shows the number of significant digits to the right of the decimal point to display when showing metric values. The last digit will be rounded as required; however, calculations within the system are always performed at the base system resolution. For example, if the initial value was calculated as "5.254667", the display would show:

- "5.255" @ 3 digit precision

- "5.2547" @ 4 digit precision

- "5.25467" @ 5 digit precision

Autopan Options

- Enable Auto Pan – check to enable auto-panning so that when you are performing any editing action and the cross-hair cursor is active, moving the cursor past any edge of the document view window will cause the document to pan in the relevant direction.

-

Style – use the drop-down to select the style of document autopanning. The following options are available:

-

Re-Center– re-centers the display around the location where the cursor touched the edge of the main design window. It also holds the cursor position relative to its location on the board, bringing it back to the center of the display. -

Fixed Size Jump– pans across in steps defined by the Step Size value. Hold the Shift key to pan in steps defined by the Shift Step value. -

Shift Accelerate– pans across in steps defined by the Step Size value. Hold the Shift key to accelerate the panning up to the maximum step size, defined by the Shift Step value. -

Shift Decelerate– pans across in steps defined by the Shift Step value. Hold the Shift key to decelerate the panning down to the minimum step size, defined by the Step Size value. -

Ballistic– the panning will increase from the Step Size value to the Shift Step value dependent on how far past the edge of the viewing window you move the cursor. Hold the Shift key to pan in steps defined by the Shift Step value. -

Adaptive– the panning will move at a constant speed when the cursor reaches the edge of the PCB window. When there are no design objects in the region where the panning is taking place, the cursor speed then slows down.

-

- Speed – shows the current autopanning speed. Edit this field to change the speed. The measurement is set according to the Pixels/Sec or Mils/Sec options.

- Pixels/Sec – select this option to set autopanning speed in pixels per second. The number of pixels per second is set in the Speed field.

- Mils/Sec – select this option to set autopanning in mils per second. The number of mils per second is set in the Speed field.

Space Navigator Options

- Disable Roll – check this option to disable the Space Navigator function.

Polygon Rebuild

-

Repour Polygons After Modification – enable to automatically repour polygons that have been modified.

-

Repour all dependent polygons after editing – enable to automatically repour any dependent polygons.

File Format Change Report

- Disable opening the report from older versions – enable to NOT create a report when an older Altium Designer PCB file format document is opened. The report informs you that the document was created in an older version of the software and provides some information on features of the opened document that may be lost or have changed. This option is disabled by default.

- Disable opening the report from newer versions – enable to NOT create a report when a newer PCB file format is loaded in Altium Designer. The report informs you that the document was created in a newer version of the software and provides some information on features of the opened document that may be lost or have changed. This option is disabled by default.

Paste from other applications

Preferred Format – use this field to choose from the following options when pasting from external applications:

-

Metafile– processes Windows enhanced metafile data, however, if there is no enhanced metafile content, any Unicode text data will be processed. -

Text– processes Unicode text data and discards any enhanced metafile data, however, if there is no Unicode text content, any enhanced metafile data will be processed.

Move Rooms Options

Ask when moving rooms containing No Net/Locked Objects – check this option and a confirmation dialog will pop up when you try to move rooms without Net/Locked Objects.

Display

The PCB Editor – Display page of the Preferences dialog provides controls relating to the functionality of the display feature within the PCB design space.

The PCB Editor – Display page of the Preferences dialog

Display Options

- Antialiasing – check to enable anti-aliasing in 3D; uncheck to disable.

- Use Animation – use to toggle animation on/off while zooming, flipping the board, and switching layers.

Highlighting Options

- Highlight In Full – enable to have selected objects completely highlighted in the current selection color. If this option is disabled, selected objects are only outlined in the current selection color.

- Use Transparent Mode When Masking – enable to turn transparency on when objects are masked (i.e., you can see through them to objects on layers underneath the mask).

- Show All Primitives In Highlighted Nets – enable to display all primitives on hidden layers (when in single layer mode) and those primitives on the current layer for the highlighted nets. Disable this option and only all primitives of the current layer (when in single layer mode) appear or all primitives on all layers (when in multi-layer mode) appear for the highlighted nets.

- Apply Mask During Interactive Editing – enable to mask non-selected objects during interactive editing. Masking makes it easier to focus on the objects being edited as non-selected objected objects are 'faded'.

- Apply Highlight During Interactive Editing – enable if you want to have objects highlighted (which uses the system Highlight color in the View Configuration panel) when you are in interactive editing mode.

Layer Drawing Order

This region allows you to set the order in which layers are redrawn on the screen. The order that the layers appear in the list is the order in which they will be redrawn. The layer at the top of the list is the layer that will appear on top of all other layers on the screen. Select a layer in the list to alter its position using the Promote and Demote buttons as follows:

- Promote – click to move the selected layer up one position.

- Demote – click to move the selected layer down one position.

- Default – click to set the Layer Drawing Order to the system defaults.

Board Insight Display

The PCB Editor – Board Insight Display page of the Preferences dialog provides numerous controls relating to the functionality of the Board Insight feature within the PCB design space.

The PCB Editor – Board Insight Display page of the Preferences dialog

Pad and Via Display Options

- Use Smart Display Color – enable to have the software automatically control the font characteristics for the display of pad and via details. Disable this option to manually set the font characteristics.

- Font Color – click to access a standard Choose Color dialog from where you can select the font color for pad/via details. This field is not available when the option to Use Smart Display Color is enabled.

- Transparent Background – enable to display pad/via details without any visible background. Disable this option to apply a specific color using the Background Color field. This option is not available when the Use Smart Display Color option is enabled.

- Background Color – click to access a standard Choose Color dialog from where you can select a background color to be used for pad/via details. This field is not available when the Use Smart Display Color option is enabled or if the option is disabled but the Transparent Background option is enabled.

- Min / Max Font Size – shows the minimum and maximum font sizes to be used to display pad and via details regardless of the zoom level. Edit these fields to change the minimum and maximum font sizes.

- Font Name – shows the current TrueType font to be used to display pad and via details. Click to view and select a font from the list.

- Font Style – shows the current TrueType font style to be used to display pad and via details. Click to view and select an option from the list (Bold, Bold Italic, Italic, or Regular).

- Minimum Object Size – shows the current minimum size (in screen pixels) of objects that will show pad and via details. This is regardless of zoom level so that at low levels of zoom, you can still maintain visibility of pad and via details. Enter the desired size or use the up and down arrows.

Available Single Layer Modes

- Hide Other Layers - in single layer modes, only the selected layers will be shown; other layers will be hidden.

- Gray Scale Other Layers - in single layer modes, the selected layers will be highlighted; all primitives on other layers are displayed in gray scale.

- Monochrome Other Layers - in single layer modes, the selected layers will be highlighted; all primitives on other layers are displayed in the same shade of gray.

Live Highlighting

Enabled – enable to have nets highlighted when you hover the cursor over them. Disabling this option will prevent any live net highlighting.

- Live Highlighting only when Shift Key Down – enable this option to apply live net highlighting only when the Shift key is being pressed.

- Outline Color – click to access a standard Choose Color dialog from where you can select an outline color to be used.

Show Locked Texture on Objects

The locked texture is a visible cue so that you can easily tell locked objects apart from non-locked objects. The locked object texture is shown as a 'key'. Enable one of the following options:

- Never – enable this option to never show the locked texture for locked objects.

- Always – enable this option to always show the locked texture for locked objects.

- Only When Live Highlighting – enable this option to only show the locked texture for a locked object when that object is being highlighted using the live highlighting feature.

Board Insight Modes

The PCB Editor – Board Insight Modes page of the Preferences dialog provides numerous controls relating to the functionality of the Board Insight within the PCB design space.

The PCB Editor – Board Insight Modes page of the Preferences dialog

Display

-

Display Heads Up Information - enable this option to turn on the Heads Up Display. The information that is displayed is typically located in the status bar such as grid coordinates, layer, dimensions, and actions. Instead of looking in the status bar, you can now raise your head up and see this information in the design space.

- Use Background Color - enable this option so that the Heads Up information is displayed with its background transparent.

- Insert Key Resets Heads Up Delta Origin - enable this option to reset the Delta Origin to 0, 0 at the current cursor position when the Insert key is pressed. The distance horizontally and vertically that the cursor is moved from the Delta Origin can be displayed in the Heads Up display (Shift+D).

- Mouse Click Resets Heads Up Delta Origin - enable this option so that a mouse click resets the Delta Origin to 0, 0 at the current cursor position. The distance horizontally and vertically that the cursor is moved from the Delta Origin can be displayed in the Heads Up display (Shift+D).

- Hover Mode Delay - use this to control how long you want to have the cursor over an item before the hover display information appears. Click on the up or down arrow buttons (increments by 100ms) or use the slide control to increase or decrease the time delay.

- Heads Up Opacity - click on the up or down arrow buttons (increments by 1%) or move the slide control to increase or decrease the level of opacity of the Heads Up display mode, making it less or more visible. The preview panes at the bottom of the dialog show you how the display will appear.

- Hover Opacity - click on the up or down arrow buttons (increments by 1%) or move the slide control to increase or decrease the level of opacity of the hover display mode, making it less or more visible. The preview panes at the bottom of the dialog show you how the display will appear.

Insight Modes

- Grid - this grid lists the available options for which information the Heads Up display modes will show. Enable the checkboxes for the information types you would like displayed in the Heads Up and Hover columns. The Panel column options refer to information that will be displayed in the Properties panel. The Popup column options refer to information that will be displayed when using the object (Shift+X) and violation (Shift+V) pop-up windows. The Font column options control the display text in the Heads Up display modes.

- Heads Up Preview - shows the preview of the Heads Up information.

- Hover Preview - displays a preview of the board information under the cursor when the cursor has been stationary for a set period of time.

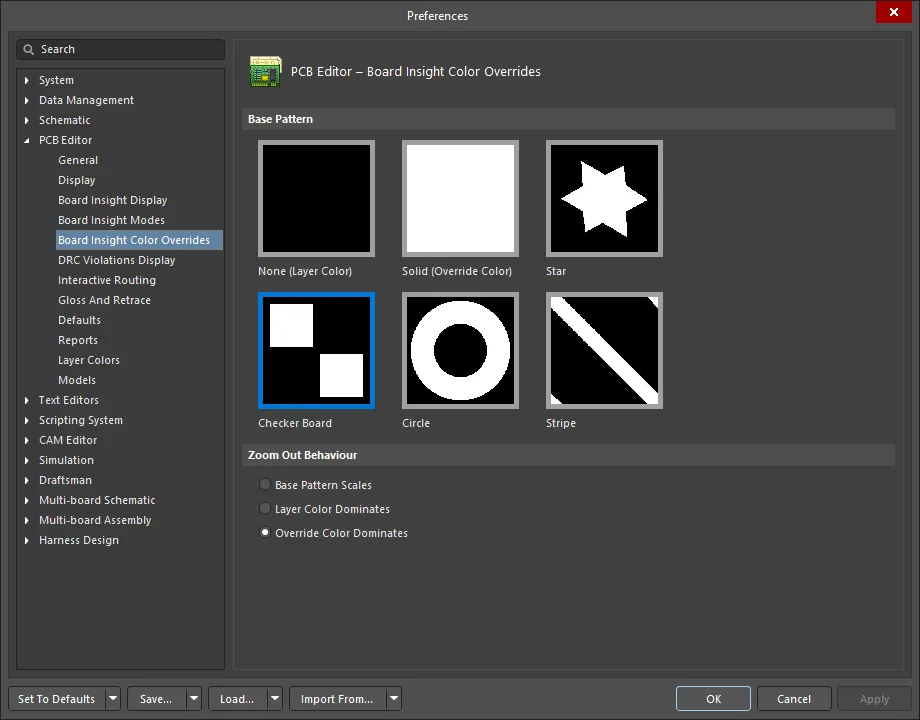

Board Insight Color Overrides

The PCB Editor – Board Insight Color Overrides page of the Preferences dialog provides controls relating to the functionality of the Board Insight Color Overrides feature within the PCB design space.

The PCB Editor – Board Insight Color Overrides page of the Preferences dialog

Base Pattern

Click to select the base pattern for the board insight color override. Patterns available are None (Layer Color), Solid (Override Color), Star, Checker Board, Circle, and Stripe.

Zoom Out Behavior

Use these options to determine how the nets are displayed when you zoom out:

- Base Pattern Scales - select to scale the base pattern as you zoom out.

- Layer Color Dominates - select to have the assigned layer color become more dominant the further you zoom out until the color is not noticeable.

- Override Color Dominates - select to have the assigned net override color become more dominant the further you zoom out until the color is not noticeable.

DRC Violations Display

The PCB Editor - DRC Violations Display page of the Preferences dialog provides a range of controls that determine the visual functionality of the DRC Violations Display feature within the PCB design space.

The PCB Editor – DRC Violations Display page of the Preferences dialog

Violation Overlay Style

Select the visual overlay style to specify how violations appear in the PCB design space. Choose from the following options:

- None (Layer Color) - the DRC override color is ignored, leaving the default layer color visible only.

- Solid (Override Color) - the DRC override color is used, totally overriding the default layer color.

- Style A - the DRC override color is used in the display of an exclamation-type pattern, leaving the default layer color also visible.

- Style B - the DRC override color is used in the display of a cross-type pattern, leaving the default layer color also visible.

Overlay Zoom Out Behavior

Use these options to determine how the overlays are displayed when you zoom out:

- Base Pattern Scales - select to scale the base pattern as you zoom out.

- Layer Color Dominates - select to have the assigned layer color become more dominant the further you zoom out until the color is not noticeable.

- Override Color Dominates - select to have the assigned net override color become more dominant the further you zoom out until the color is not noticeable.

Choose DRC Violations Display Style

This region presents a grid allowing you to choose the display style used on a per-rule basis.

- Enabling the Violation Details field for a rule type will use the associated custom violation graphics to display the DRC violations of that rule.

- Enabling the Violation Overlay field will display the violations using the specified overlay style.

Right-click anywhere in the region to access a context menu, with commands to quickly enable or disable use of a violation display type for all rule types. You can also quickly enable the display of violations – detailed graphics or overlay styles – for only those rules currently being used in the design.

Interactive Routing

The PCB Editor – Interactive Routing page of the Preferences dialog provides numerous controls relating to the functionality of the Interactive Routing feature within the PCB design space.

Routing Conflict Resolution

-

Ignore Obstacles - select to have the interactive router to allow placing tracks anywhere, including over existing objects, displaying but allowing potential violations.

-

Push Obstacles - select to have the Interactive Router move existing tracks out of the way while routing. This mode can also push vias to make way for the new routing. If the system cannot push an obstacle without causing a violation, an indicator appears to show the route is blocked.

-

Walkaround Obstacles - select to have the Interactive Router route around existing tracks, pads, and vias without attempting to move them while routing. If the system cannot walk around an obstacle without causing a violation, an indicator appears to show the route is blocked.

-

Stop At First Obstacle - select to have the Interactive Router stop routing when it encounters the first obstacle in its path. In this mode, the routing is essentially manual, i.e. as soon as an obstacle is encountered, the track segment will be clipped to avoid a violation.

-

Hug And Push Obstacles - select to have the Interactive Router hug existing tracks, pads, and vias as closely as possible while routing and, where necessary, push obstacles when there is insufficient clearance to continue using Walkaround. If the system cannot hug or push an obstacle without causing a violation, an indicator appears to show the route is blocked. Efficiently, this mode is a combination of Walkaround and Push.

-

AutoRoute On Current Layer - select to enable auto-routing on the current layer. This mode applies basic autorouter intelligence to the interactive router, automatically selecting between pushing and walking around based on heuristics that consider push distance versus walk distance and route length, to give the shortest overall route length. Like an autorouter, this mode can deliver better results on a complex, busy board than on a simple, unrouted board.

-

AutoRoute On Multiple Layers - select to enable auto-routing on multiple layers. This mode also applies basic autorouter intelligence to the interactive router, automatically selecting between pushing and walking around based on heuristics that consider push distance versus walk distance and route length, to give the shortest overall route length. This mode can also place a via and consider using other routing layers. Like an autorouter, this mode can deliver better results on a complex, busy board than on a simple, unrouted board.

-

Current Mode - this field displays the current Routing Conflict Resolution mode chosen when using the Interactive Router. Use the associated drop-down to change the mode as required.

Interactive Routing Options

- Automatically Terminate Routing – when enabled, when you complete a route to the target pad, the routing tool does not continue in routing mode from the target pad but instead resets, ready for you to click on the next source pad from which to route. If this option is disabled, after you route to the target pad, the tool will remain in routing mode, using the previous target pad as the source for the next route.

-

Automatically Remove Loops – enable to automatically remove any redundant loops that are created during manual routing. This allows you to re-route a connection without having to manually remove redundant tracks. However, there are times when you need to route nets (such as power nets) and you need loops. In this case, you can toggle the Remove Loops option for a selected net by editing its net property from the Edit Net dialog via the PCB panel. The Remove Loops local setting for the specified net overrides this global setting for the same net.

- Remove Loops with Vias – enable to automatically remove loops with vias. Disable this option for vias to remain during loop removal.

- Remove Net Antennas – enable to automatically remove any track or arc end that is not connected to any other primitive and therefore forms an antenna.

- Allow Via Pushing – check this option to allow pushing vias when you are in Push Obstacles or HugNPush Obstacles mode (selected above in Current Mode).

-

Display Clearance Boundaries – with this option enabled, as you interactively route, the no-go clearance area defined by the existing objects and the applicable clearance rule is displayed as shaded polygons giving you an indication of just how much space you have available for routing.

- Reduce Clearance Display Area – by default, all clearance boundaries are displayed, however, you can opt to reduce the clearance display area by enabling this option to only view boundaries that fall within a localized viewing circle.

-

Apply Trace Centering – enables the trace centering functionality. When enabled, an additional clearance is added between the net being routed and existing pads/vias where possible and the following options are available to configure the functionality:

-

Adjust Vias – when the option is enabled, vias will be pushed to maintain the additional clearance where possible.

-

Added Clearance Ratio – a multiplier of the applicable clearance, which is then added to the clearance. For example, if the applicable clearance is

0.15 mm, setting the option to 2 would instruct the routing engine to clear existing pads and vias by0.15 + 2 * 0.15 = 0.45 mmwhere possible. The routing engine can then reduce this clearance down to the specified clearance if required.

Refer to the Interactive Routing page to learn more about trace centering.

-

- Auto Shrinking – check this option to automatically shrink the routing width to a value that would allow routing in locations where the trace cannot be routed between obstacles with the currently chosen routing width. Refer to the Interactive Routing page to learn more about routing auto-shrinking.

General

To help produce routing with the minimum number of corners, the PCB Editor includes a Glossing tool. Glossing is a sophisticated set of algorithms developed specifically to produce cleaner routing and pad entries, that respect the intent of the applicable design rules. Glossing attempts to reduce the path length and also improve the shape of corners and reduce their number, generally resulting in neater routing created from fewer segments.

-

Gloss Effort (Routed) - has three settings; Off, Weak, and Strong. Use the Ctrl+Shift+G shortcut to cycle through the settings during routing.

- Off - In this mode, glossing is essentially disabled. Note, however, that cleanup is still run after routing/dragging occurs to eliminate, for example, overlapping track segments. This mode is typically useful at the end stage of board layout when the ultimate level of fine-tuning is required (for example, when manually dragging tracks, cleaning pad entries, etc.).

- Weak - In this mode, a low level of glossing is applied with the Interactive Router considering only those tracks directly connected to or in the area of the tracks that you are currently routing (or tracks/vias being dragged). This mode of glossing is typically useful for fine-tuning track layout or when dealing with critical traces.

- Strong - In this mode, a high level of glossing is applied with the Interactive Router looking for shortest paths, smoothing out tracks, etc. This mode of glossing is typically useful in the early stages of the layout process when the aim is to get a large portion of the board routed quickly.

Push and shove interactive routing allows you to push existing routes to make room for a new route. This can sometimes be at the expense of the existing routes; while their new locations might satisfy the design rules, the quality of their placement might be compromised. To help manage this, the interactive routing's glossing tool supports neighbor routes; that is, glossing all existing routes that have been impacted by the push and shove process.

- Gloss Effort (Neighbor) - has three settings; Off, Weak, and Strong. Use the Ctrl+Shift+G shortcut to cycle through the settings during routing.

- Hugging Style - use the drop-down to choose between the 45 degree, mixed, or rounded hugging styles. This option controls how corner shapes are to be managed during interactive sliding and will affect both the tracks being slid and the tracks being pushed.

-

Minimum Arc ratio - enter the desired minimum arc ratio. The Minimum Arc Ratio may be applied during any angle interactive routing and also during interactive sliding with Mixed Hugging style. The ratio is used to determine the minimum radius arc allowed when the arc radius falls below this minimum the arc is replaced by track segments, where

Min Arc Radius = Min Arc Ratio x Arc Width. - Miter Ratio - enter the desired miter ratio, which may be used to control the minimum corner tightness. The Miter Ratio multiplied by the current track width equals the separation between walls of the tightest U-shape that can be routed for that ratio. You may enter a positive value equal to or greater than zero (the x multiplier is added automatically).

- Pad Entry Stability - enter the desired level of protection for centered pad entries. The higher the number, the greater protection; '0' gives no protection.

Dragging

-

Preserve Angle When Dragging - enable this option to preserve the angle when dragging. When enabled, select one of the following options:

-

Ignore Obstacles- obstacles will be ignored to preserve angle during dragging. -

Avoid Obstacles (Snap Grid)- based on the snap grid, the software will try to avoid obstacles while preserving angles. -

Avoid Obstacles- software will try to avoid obstacles during dragging.

-

-

Disable Trace Centering When Dragging - when this option is enabled, trace centering is not applied during interactive sliding (even if the Apply Trace Centering option is enabled).

-

Vertex Actions - choose the desired vertex action to use, which will be seen when clicking and dragging on a vertex. There are specific options that are applied when you click and drag on a vertex rather than a track or arc (the vertex is the corner location where two segments meet). Use the Spacebar shortcut to cycle through the available modes during sliding. The drop-down options include the following:

- Deform - break or lengthen the track segments attached to the moving vertex so that the vertex follows the cursor movement.

- Scale - hold the corner shape and resize and move the incoming track segments, keeping the vertex attached to the cursor.

- Smooth - reshape the corner smoothly, inserting arcs to create a curved corner when dragging inward (in Mixed or Rounded Hugging Style), at every vertex impacted by the sliding process. Also, add arcs when dragging outward in Rounded Hugging Style.

-

Unselected via/track - set the default behavior of dragging an unselected via or track to be either a

MoveorDragaction. -

Selected via/track - set the default behavior of dragging a selected via or track to be either a

MoveorDragaction. -

Component pushing - this field displays the current Component Conflict Resolution mode when moving components within the design space. The following modes are supported:

- Ignore - default behavior, where the component can be moved regardless of creating a violation with neighboring component(s). In this mode, the same component clearance checking routines seen in previous versions of Altium Designer are used. These routines use the 3D body (if there is one) or the copper and silk primitives to identify an object's clearance.

- Push - the component will push other components away to provide compliance with clearances between components. Components in unions can be pushed and the location of components in the union may change but the union will not break. Locked components cannot be pushed. In this mode, components are identified by their selection boundary, which is the smallest possible rectangle that encloses all of the primitives in the component.

- Avoid - the component will be forced to avoid violating component clearance rules between other components. In this mode, components are identified by their selection boundary, which is the smallest possible rectangle that encloses all of the primitives in the component.

-

Component re-route - check the box to toggle the post-drop connectivity restoration. After the set of objects being moved has been released, the software will attempt to re-route the component(s) to reconnect any broken nets. Use the Shift+R shortcut to inhibit the re-route behavior (disabling the option). Note that component re-routing is not applied to a moved component if that component is a member of a union.

-

Move component with relevant routing - enable this option to start the move component action with the relevant routing (Components +Via Fanouts +Escapes +Interconnects). Use the Shift+Tab shortcut to cycle the selection set. Disable the option to start the move component action with components only selected. Because the set of relevant routing objects is detected prior to the move commencing, it is not possible to use Shift+Tab to cycle through the selection set when the option is disabled.

- up to - when the Move component with relevant routing option is enabled, specify the number of pins. The default value is 2. If a component has more pins than specified in this field, the Move component with relevant routing option will not "work" and relevant routing will not be moved with the component.

Interactive Routing Width Sources

- Pickup Track Width From Existing Routes - enable to use the existing track width when routing from a placed track (i.e. even if the current routing width is different to the existing track, the existing track width will be adopted when you continue the route from it).

-

Track Width Mode - choose a track width mode for interactive routing. The available modes are:

-

User Choice- with this mode enabled, the width is determined from the width selected in the Choose Width dialog, which is accessed by pressing Shift+W while routing. -

Rule Minimum- with this mode enabled, the design rule minimum width defined for the current net will be used. -

Rule Preferred- with this mode enabled, the design rule preferred width defined for the current net will be used. -

Rule Maximum- with this mode enabled, the design rule maximum width defined for the current net will be used.

-

-

Via Size Mode - choose one of the via size modes for interactive routing. The available modes are:

-

User Choice- with this mode enabled, the via size is determined from the size selected in the Choose Via Sizes dialog, which is accessed by pressing Shift+V while routing. -

Rule Minimum- this mode uses the minimum via size rule. -

Rule Preferred- this mode uses the preferred via size rule. -

Rule Maximum- this mode uses the maximum via size rule.

-

Favorites

Favorite Interactive Routing Widths - click to open the Favorite Interactive Routing Widths dialog in which you can configure routing widths.

The Favorite Interactive Routing Widths dialog

Things to note:

- Entries without shading indicate that the preferred system units will be used when those widths are chosen. The board units are switched automatically.

- Double-click an entry (or select and click the Edit button) to access the Preferred Routing Width dialog in which the value for the width can be changed as required.

-

Click the Add button to open the Preferred Routing Width dialog to add a new routing width to the list. If you enter a value with no units, it will default to Imperial preferred system units. To control the preferred system units used for the width, ensure to specify the units (especially if Metric is desired).

The Preferred Routing Width dialog

Gloss And Retrace

The PCB Editor – Gloss And Retrace page of the Preferences dialog provides numerous controls relating to the functionality of the Gloss Selected and Retrace Selected features within the PCB design space.

The PCB Editor – Gloss And Retrace page of the Preferences dialog

Gloss & Retrace Parameters

-

Hugging Style – controls how corner shapes are to be managed during glossing or retracing.

- 45 Degree – always use straight orthogonal/diagonal segments to create corners during glossing or retracing (use this mode for traditional orthogonal/diagonal routing behavior).

- Rounded – use arcs at each vertex involved in the glossing or retracing. Use this mode to use arcs + any angle routes when glossing.

- Avoid polygons – when this option is enabled, existing polygons will be respected when the Gloss Selected or Retrace Selected command is run. If the option is disabled existing polygons will be ignored (routed across), affected polygons can then be repoured.

- Avoid rooms – when this option is enabled, existing rooms will be respected when the Gloss Selected or Retrace Selected command is run. If a room scoped by specific routing width requirements is defined in the design and the routing to be glossed/retraced does not cross the room, the resulting routing will not cross this room either when the option is enabled. If the option is disabled, existing rooms will be routed across, and the width to be used within such rooms will be that is defined in constraints of the room-based rule.

-

Pad Entry Stability – enter the desired level of protection for centered pad entries. The higher the number, the greater protection; '

0' gives no protection; '10' gives maximum protection. - Miter Ratio – controls the minimum corner tightness. The Miter Ratio multiplied by the current track width equals the separation between walls of the tightest U-shape that can be routed for that ratio. Enter a positive value equal to or greater than zero.

Gloss Parameters

Effort – select the desired gloss level from the following choices:

- Weak – in this mode, a low level of glossing is applied. This mode of glossing is typically useful for fine-tuning track layout or when dealing with critical traces.

- Strong – in this mode, a high level of glossing is applied, with a strong emphasis on the shortest path. This mode of glossing is typically useful in the early stages of the layout process when the aim is to get a good amount of the board routed quickly.

Retrace Parameters

-

Set Width – use the drop-down to select one of the rule-based width options (Min / Max / Preferred) of an applicable Width or Differential Pairs Routing design rule when the Retrace Selected command is run, or select the Current width of tracks to be retraced. Alternatively, enter a desired custom width value directly in the field.

-

Set Diff Pair Gap – use the drop-down to select one of the rule-based gap options (Min / Max / Preferred) of an applicable Differential Pairs Routing design rule when the Retrace Selected command is run, or select the Current gap between differential pair tracks to be retraced. Alternatively, enter a desired custom gap value directly in the field.

-

Preserve route path – enable to preserve the exact trace geometry during Retrace. When this option is enabled, the Retrace algorithms will not modify the centerline of the trace. Tracks may change width and be split into segments of different widths, but the trajectory will not be changed.

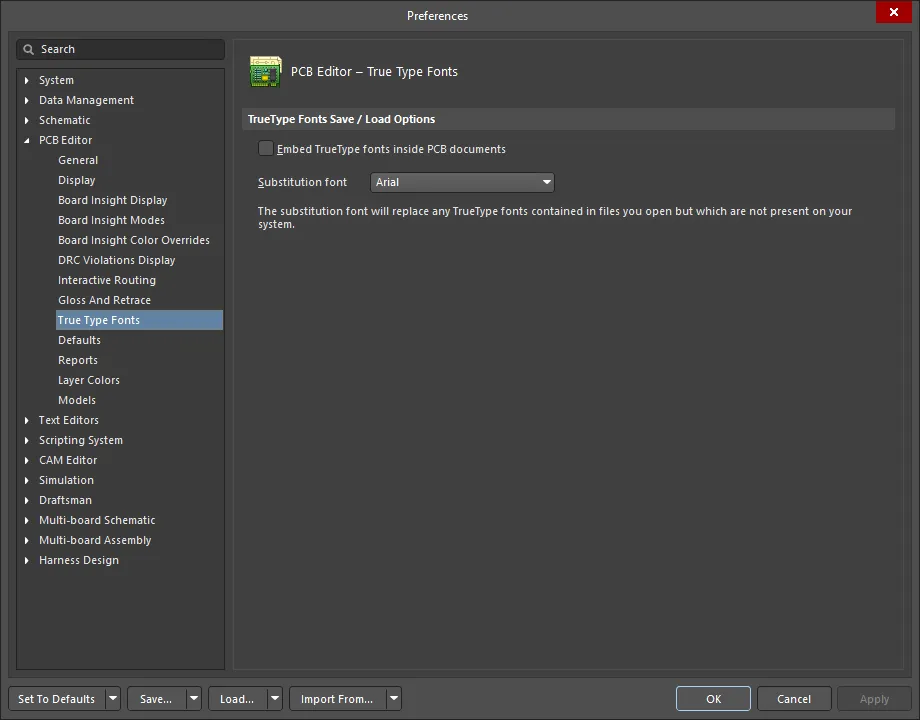

True Type Fonts

The PCB Editor – True Type Fonts page of the Preferences dialog provides numerous controls relating to the functionality of the True Type Fonts feature within the PCB design space.

Refer to the PCB Placement & Editing Techniques page to learn more about TrueType font support in the PCB editor.

The PCB Editor – True Type Fonts page of the Preferences dialog

TrueType Fonts Save / Load Options

- Embed TrueType fonts inside PCB documents - TrueType fonts are the fonts installed on your computer. Enable this setting to save the TrueType fonts you have used in your PCB file. This will allow other machines that do not have a specific font to view the design as you have intended.

- Substitution font - the substitution font will replace any TrueType fonts contained in files you open but that are not present on your system. Use the drop-down to select the desired font.

Defaults

The PCB Editor – Defaults page of the Preferences dialog provides numerous controls relating to the default settings within the PCB design space.

The PCB Editor – Defaults page of the Preferences dialog

Default Primitives

-

Primitives - use this field to filter the presented listing of primitives.

-

Primitive List - a list of primitives that can be used in the PCB editor (filtered in accordance with the chosen entry for the Primitives field above). Click on the listed Primitives to change the available default values as described.

To view and edit the settings and options for each primitive, click on the desired entry in the Primitive List.

For more information about PCB design objects, refer to the QuickNav - PCB Design Objects page.

Additional Controls

-

Save as - click to save the current default object properties to a custom properties file (*.dft). You will be asked for a name and directory for the file. When the PCB editor server is started, the current defaults are read and any changes you make to the defaults are stored in this file when you exit. Use the Load button to load a previously saved set of default properties.

-

Load - click to load a previously saved set of default object properties. You will be asked to navigate to and select a previously saved properties file (*.dft).

-

Reset All - click to reset the properties of all objects to the system defaults.

-

Permanent - if this option is enabled, the default properties of all object types are locked and are not changed if you edit an object's properties during placement. If this option is disabled, any changes you make to a particular object during placement (by pressing the Tab key while the object is floating on the cursor before placement to open the Properties panel) are used to update the default properties for that particular object type.

Reports

The PCB Editor – Reports page of the Preferences dialog provides numerous controls relating to the functionality of the Reports feature within the PCB design space.

The PCB Editor – Reports page of the Preferences dialog

Reports

The PCB reports displayed in this list can be created as text, HTML, or XML files. Enable the Show option to show (open) the report after it has been created. Enable the Generate option to generate the report. The XSL template is displayed in the XML Transformation Filename column. This path can be modified if desired.

Supported reports are:

- Design Rule Check

- Net Status

- Board Information

- BGA Escape Route

- Move Component(s) Origin to Grid

- Embedded Boards Stackup Compatibility

Layer Colors

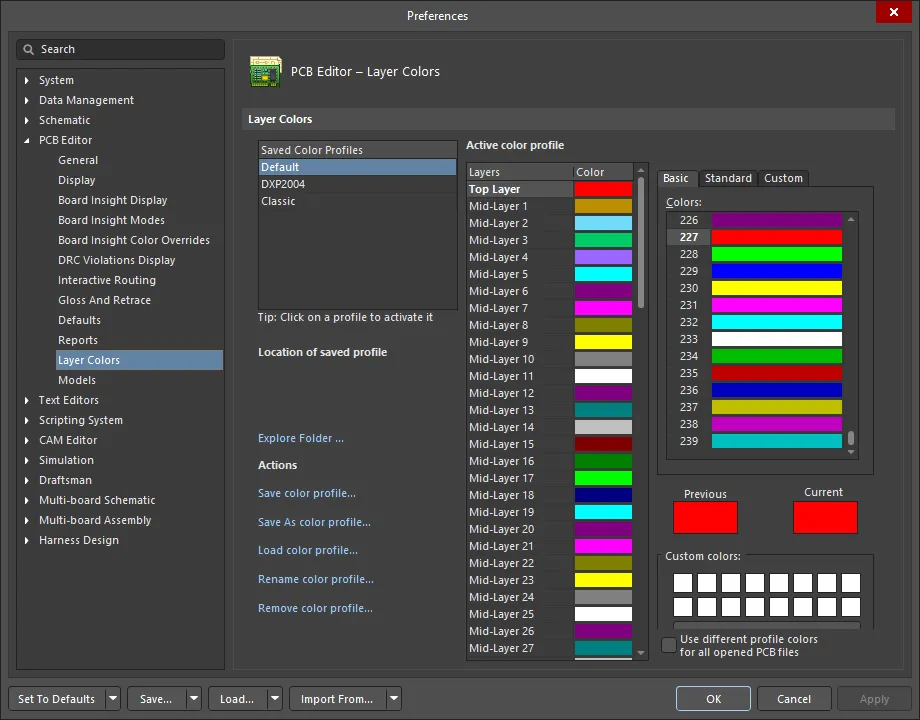

The PCB Editor – Layer Colors page of the Preferences dialog provides controls to change the colors used for all supported board layers and system objects associated with viewing a board in 2D. Quickly change the color of a chosen layer or all layers on the fly. Alternatively, define a color profile to determine the colors assigned to each and every layer. Color profiles can be saved and loaded to enable the quick application of favorite/desired color schemes.

The PCB Editor – Layer Colors page of the Preferences dialog

Layer Colors

-

Saved Color Profiles - lists the names of the currently saved color profiles. Click on an entry to 'activate' it. This allows you to view the colors configured for the layers in that profile in the Active color profile region of the dialog and make any changes as required.

- Location of saved profile - shows the file path of a saved 2D color profile. Hover the cursor over an entry in the Saved Color Profiles list to see the path here.

- Explore Folder - click to open the folder in which the saved color profiles are located.

-

Actions – this region presents various commands for working with color profiles at the file level (

*.PCBSysColors):- Save color profile – click to save any changes made to layer colors for the currently selected color profile.

- Save As color profile – click to access the Save Color Profile As dialog from where you can save the currently selected color profile as a distinct, new profile with a different name. The newly saved color profile will be added to the list of saved color profiles.

-

Load color profile – click to access the Load Color Profile File dialog from where you can browse to and open a color profile file (

*.PCBSysColors). The chosen color profile will be added to the list of saved color profiles. - Rename color profile – click to access the Rename Color Profile dialog from where you can specify a new name for the profile as required.

-

Remove color profile – click to remove the selected color profile. A confirmation dialog will appear. Click No to remove the profile from the saved color profiles list. Click Yes if you want to also remove the color profile file from the hard disk.

- Active color profile - this region provides controls to configure the layer colors for the active color profile, i.e., the profile currently selected in the Saved Color Profiles list.

-

Layers - lists all supported board layers as well as system layers. For each layer in the list, its currently assigned color is displayed in the color swatch to the right. To change the color for a layer, simply select it in the list, then use the controls to the right to choose a new color.

-

Selection region - the region to the right of the layers list offers the same controls as those found in the standard Choose Color dialog. Three tabs are available, essentially giving you simple and advanced modes for choosing the required layer color:

- Basic - this tab provides a flat listing of colors.

- Standard - this tab provides a hexagonal color selector filled with popular colors, as well as controls for quickly choosing black, white, or various shades of gray.

- Custom - this tab provides advanced controls for getting the exact shade of color required. Use the main color area to drag the cross-hair to the 'ball park' color required, then use the vertical slider bar to the right to fine-tune the shade. Use the Color model drop-down field to choose between two color models, either RGB (Red, Green, Blue) or HSL (Hue, Saturation, Luminance). The fields below update as you change the color controls above. Alternatively, enter the values for Red, Green, and Blue directly.

-

Previous - shows the previous color used for the selected layer.

- Current - shows the new color chosen for the layer. This color will be applied during the current editing session with the software (if simply clicking OK), and/or will be committed to the color profile, if that profile is saved.

-

Custom Colors - this area allows you to store up to 16 custom colors, which is useful if you have finally reached a required color through the color selecting controls and want to effectively 'save' that color for reuse. Clicking on any of the custom color swatches will quickly assign its color as the current layer color.

- Add to Custom Colors - use this button to add the currently chosen color to the custom color palette.

- Use different profile colors for all opened PCB files - enable this option to display layer colors according to the assigned profile for all opened PCB documents. This option is disabled by default.

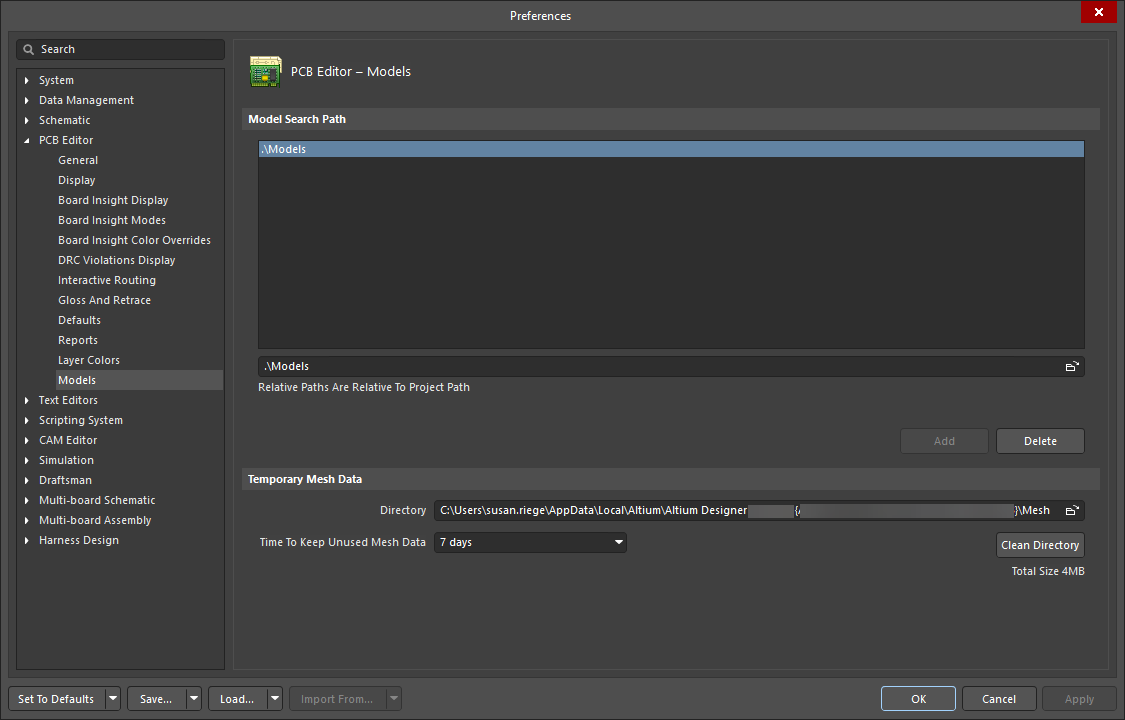

Models

The PCB Editor – Models page of the Preferences dialog provides numerous controls relating to Models within the PCB design space.

The PCB Editor – Models page of the Preferences dialog

Model Search Path

- Models region - lists all folders that will be defaulted to when linking 3D STEP model files via the Properties panel in 3D Body mode. You might consider these folders "watched" since the software monitors changes to STEP files (*.stp, *.step) in them.

- Models path - click the browse icon on the right to open a dialog in which you can browse for a folder in which to search for 3D STEP model files. Once the folder is found, add it to the Models region using the Add button. Whenever you link or embed a STEP model to a component footprint or PCB document, the folders listed in the Models region list are defaulted to. The idea of using common or central depositories for STEP model files can be beneficial, particularly in multi-user environments.

- Add - click to add the folder currently displayed in the browse bar to the Models region list.

- Delete - click to remove the currently selected folder from the Models region list.

Temporary Mesh Data

- Directory - click the browse folder icon to open a dialog to browse for a folder in which the software will store 3D model mesh data. Mesh data is calculated for display purposes when a 3D model is first used or created. This data is saved, to be used whenever that model is required again. Storing mesh data in this way can improve system performance when working in the 3D design space.

-

Time To Keep Unused Mesh Data - click to view and select a maximum period of time (in days) for the system to store 3D model mesh data since its last use before deleting it. Mesh data is calculated for display purposes when a 3D model is first used or created. This data is saved, to be used whenever that model is required again. Storing mesh data in this way can improve system performance when working in the 3D design space. Available options are:

-

1 day -

2 days -

7 days -

30 days

-

- Clean Directory - click to immediately empty the folder used to store temporary 3D model mesh data.