Including Barcodes & Logos on a PCB in Altium NEXUS

Parent page: Finalizing the Board Design

Your Altium Design Software's PCB Editor provides the ability to place barcode symbols directly onto any layer of a PCB, allowing barcodes to be easily imprinted on a PCB as part of the manufacturing process. In addition, the editor supports several methods for adding graphical images to a PCB design document, which is great for getting your company logo on board!

Adding a Barcode

The software provides the ability to place barcode symbols directly onto a PCB on any layer, allowing barcodes to be easily imprinted on a PCB as part of the manufacturing process. Barcodes are commonly used to tag and identify PCBs, streamlining inventory tracking for example, through the use of automated scan-machines. A barcode is placed within a PCB document as a configured String object. Use the Place » String command to commence placement.

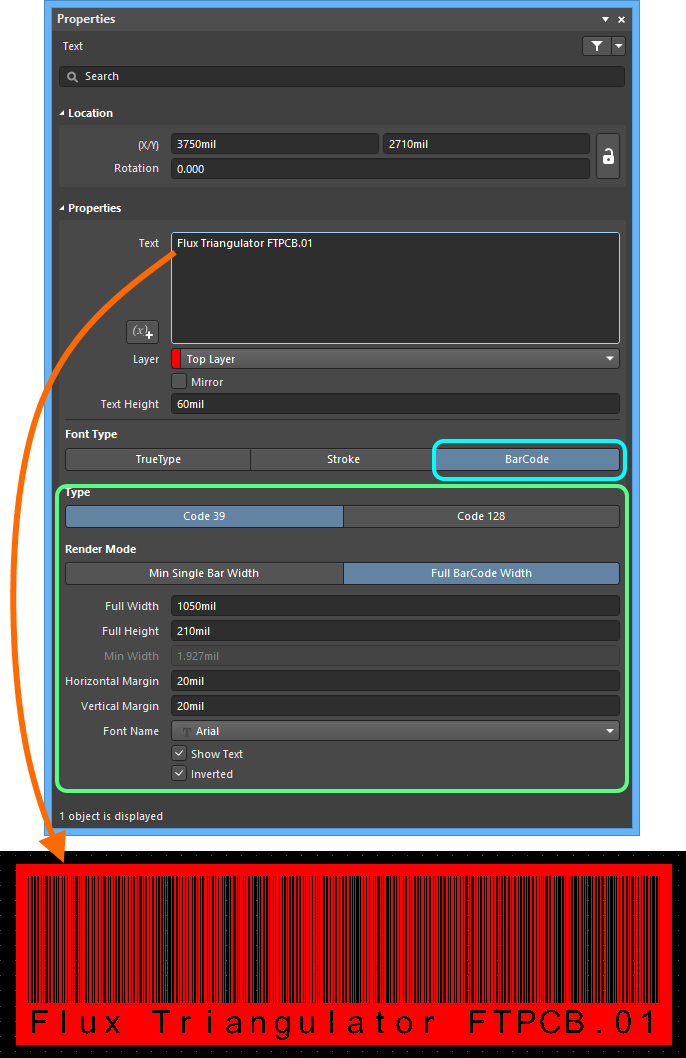

To use a Barcode font, first select the string object to access its properties through the Properties panel. Then, simply set the Font Type to BarCode, and define the display options as required in the region below. BarCode ISO Code 39 (US Department of Defense standard) and Code 128 (global trade identification standard) are supported, and the actual text string that the barcode is derived from can also be displayed by enabling the Show Text option.

Example barcode with original (human-readable) text beneath.

Example barcode with original (human-readable) text beneath.

By using a combination of barcode and inverted text strings, along with fills if necessary, a nice barcode area can be defined on a board, with more information textually than would otherwise be afforded by just the originating barcode text, as shown below.

Example using inverted barcode and additional inverted text strings.

Example using inverted barcode and additional inverted text strings.

Adding a Graphic

Typically when fabricating a board, the owner company - the company that designed the board and hopes to make a tidy profit from its commercial availability and success - will want to 'stamp' its ownership. Sure this can be achieved through simple text on the silkscreen layer, but more often than not, the company's logo is a far more eye-catching and effective alternative. Catering for this requirement, the software's PCB Editor supports several methods for adding graphical images to a PCB design document.

Placing a Graphic as a Font

It is possible to create a custom TrueType font that contains a graphic as a glyph (one of the characters in the font) and then place a string on the PCB board that uses that font. As well as the ease of use, another great advantage of this method is that if the font glyphs are created from vector graphic images, then they can be accurately scaled.

A font of many standard symbols used in PCB design - including: lead free, recycle, static sensitive, Earth, C-Tick, UL, CE, FCC, and many others - has been created by one of the leading experts in designing with Altium Design Software - Darren Moore from Mooretronics. The font is available for download here (dated June 2015), and you can also check the related forum thread, for more recent versions in the latest posts.

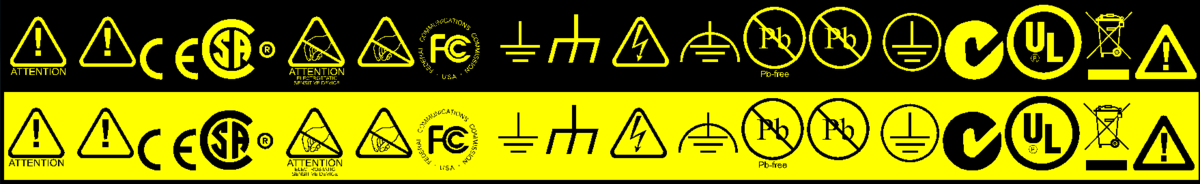

The font is licensed as Cardware, refer to the Readme.txt included in the downloaded ZIP for conditions of use. The readme also includes a list of the available graphics. Note that many are available with text or without text, the preferred version is chosen by using the upper or lower case letter. The image below shows a sample of the graphics available in the font.

A sample of some of the useful graphics in the Mooretronics font.

A sample of some of the useful graphics in the Mooretronics font.

Placing a Graphic on the PCB

To place a graphic on the PCB, select the Place » Graphics command to place a JPG, BMP, PNG or SVG format graphic.

After launching the command, you will be prompted to provide two clicks to define a rectangular area for the image to be placed in. You will then be prompted to select the graphic file, once it has been selected the Import Image dialog will open. Configure the image settings as required and click OK to create the graphic on the active PCB layer.

Notes:

- The image will be imported and scaled to fit in the largest available vertical or horizontal distance within the rectangular area you defined, maintaining its original aspect ratio.

- If the graphic is placed as a Union then it can be moved (click and drag) or resized (right-click » Unions » Resize Union) as a single object.

Pasting a Metafile Directly from the Windows Clipboard

For a logo, the PCB editor also supports pasting a metafile directly from the Windows clipboard onto the current PCB layer using the standard Windows Ctrl+V paste command. Supported metafile data includes bitmaps, lines, arcs, simple fills, and true type text - allowing you to easily paste logos and other graphical symbols.

Note that not all image editors place the image data into the clipboard as metafile data. One approach to ensure this happens is to first paste the image into Microsoft Word then copy it from there and paste it into your Altium NEXUS software. To do this:

- Paste or insert the desired logo image (in BMP or PNG format) into a Microsoft Word document. It is recommended to either copy/paste the image from an image editor into Word or use Word's Insert » Picture command, as Word treats an image that is dragged and dropped into an open Word file differently from an image that is pasted or inserted.

- Highlight the image in Microsoft Word and copy it to the clipboard.

- Open the required target PCB document in Altium NEXUS.

- Paste the image from the clipboard (Edit » Paste or Ctrl+V).

- The image will appear floating on the cursor. Click at the desired location in the workspace to effect placement.

Imported data will be put onto the current layer, adopting the color you have chosen for that layer. The PCB objects created during the paste process are automatically added to a Union. After pasting, the Union's editing handles can be used to fine-tune the size of the pasted image. Unions resulting from a paste can also be resized at any time using the Resize Union command from the right-mouse menu (click to select the required union after launching the Resize Union command).

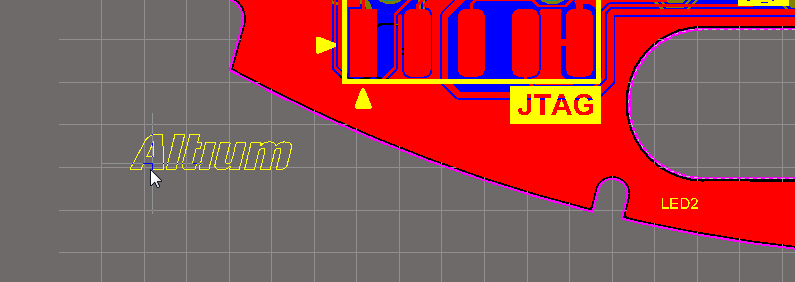

The Altium logo being pasted as a graphic; each letter in the graphic is converted into a region object.

The Altium logo being pasted as a graphic; each letter in the graphic is converted into a region object.

Placing as an OLE Object

A graphic stored in BMP format can also be placed as an OLE object onto the active PCB document. This is made possible through Object Linking and Embedding (OLE) technology in the PCB Editor.

First, make the layer on which you wish to place the OLE Object data the active layer in the workspace. After launching the command (Place » Object From File), the standard Windows Choose file dialog will appear. Use this dialog to browse to the required BMP image file. After clicking Open, the data from the chosen file will appear floating on the cursor. Position as required within the workspace and click, or press Enter, to effect placement.

Placing a BMP image, as an OLE object, onto a PCB document.

Placing a BMP image, as an OLE object, onto a PCB document.