3Dモデルの向きと位置の調整

MCADモデルをコンポーネントのフットプリント付近に配置したら、位置決めを行えます。3DのMCADモデルは、フットプリントに合わせるために向きを再調整する必要があるのが一般的です。

この作業を支援するためのツールや機能が多数用意されています。

一般に、回転作業は3D表示モードで行うのが簡単で、スナップポイントをフットプリント上の位置に合わせるといったX-Y方向の位置決め作業は2D表示モードで行うのが簡単です。

参照点とスナップポイント

参照点(Reference Point)とスナップポイント(Snap Point)は、配置中に3D Bodyオブジェクトを保持するための方法を提供します。Snap to CenterオプションがPCB Editor – General page (Preferencesダイアログ内)で有効になっている場合、オブジェクトを移動するためにクリックして押し続けると、カーソルは最も近い頂点/参照点/スナップポイントに自動的にスナップします。

汎用モデルには、設計に使用したMCADソフトウェア側で参照点が割り当てられています。

スナップポイントはユーザー定義の位置で、設計空間内で移動する際にその位置でオブジェクトを保持できるようにします。スナップポイントは通常、オブジェクトのエッジやコーナー、または中心位置(例:ピンや取付け用ペグの中心)に割り当てます。スナップポイントは3Dオブジェクト上の参照マーカーとして使用され、PCB上またはPCBフットプリント上のプリミティブや他のスナップポイントに対して3D Bodyの向き合わせや整列を行う際に役立ちます。スナップポイントは、モデル種別(押し出し、円柱、球、リンク/埋め込みモデル(STEP、Parasolid、SOLIDWORKS)、またはWorkspaceから参照される3Dモデル)に関係なく、任意の3D Bodyに追加できます。

スナップポイントは、PropertiesパネルのSnap Points領域でX、Y、Z座標を入力して追加することも、Add Snap Points From Verticesコマンドを使って対話的に追加することもできます。スナップポイントの対話的な追加は、3Dモードの方が簡単です。

スナップポイントを追加するには:

-

3を押して3Dレイアウトモードに切り替えます。

-

Tools » 3D Body Placement » Add Snap Points From Verticesコマンドを選択します。

-

ステータスバーに表示されるとおり、次の手順はPick the STEP model to add snap points toです。クリックして目的の3D Bodyオブジェクトを選択します。カーソルは3D位置決めカーソル(青色の六芒星)に変わります。

Add Snap Points From Verticesコマンドには2つのモードがあります(Spacebarでモードを切り替えます):

-

単一の頂点をクリックして、その位置にスナップポイントを追加する、または

-

2つの別々の頂点をクリックすると、その中間にスナップポイントが追加されます。この手法を使うと、部品ピンの中央にスナップポイントを追加できます。

-

Spacebarを押して必要なモードを選択します。

-

頂点をクリックしてスナップポイント位置を定義します。3Dカーソルを3Dモデル表面上で移動します。ローカル頂点の近くに来ると、3Dカーソルは磁力のようにその頂点へ引き寄せられます。

-

2クリックモードを使用している場合は、2つ目の頂点をクリックして2つ目の位置を定義します。スナップポイントは2つのクリック位置の中間に作成されます。

-

スナップポイントの配置を続けるか、右クリックするか、Escを押してコマンドを終了します。

選択したモデルに追加されたスナップポイントは、選択モデルのプロパティをPropertiesパネルで表示したときに、Snap Points セクションに一覧表示されます。

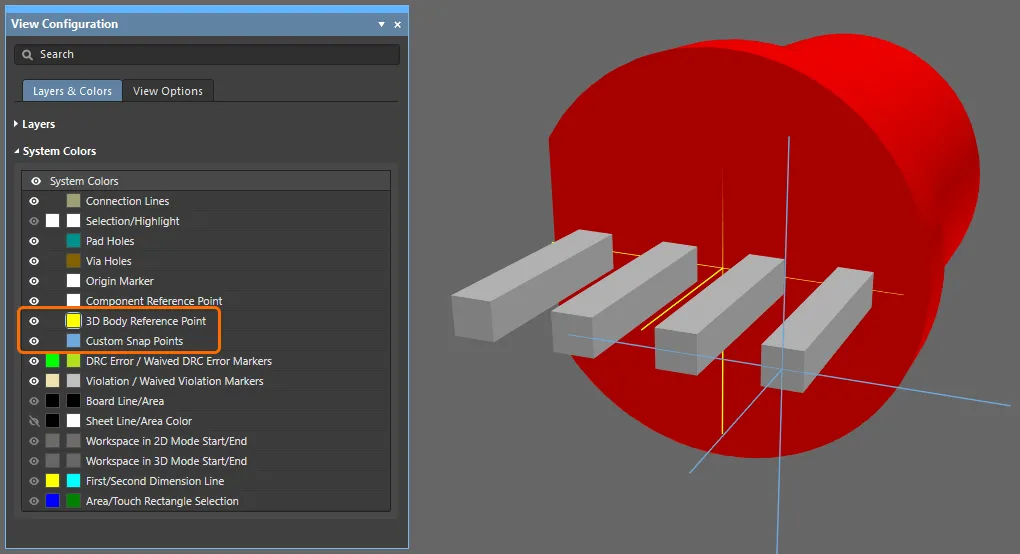

3D Bodyの参照点およびカスタムスナップポイントの表示/非表示は、View Configuration panelのSystem Colors領域にあります。

選択した3D Bodyの頂点からスナップポイントを削除するには、メインメニューからTools » 3D Body Placement » Remove Snap Points コマンドを選択します。対象の3Dモデル上にカーソルを置いてクリックし、その後3Dカーソルを3Dモデル表面上で移動します。3Dカーソルは既存のスナップポイント間でのみ移動します。3Dカーソルがスナップポイント上にある状態でクリックすると、そのスナップポイントが削除されます。

3Dモデルの中心スナップ

3Dモデルへのスナップポイント追加の利便性と精度を向上させるため、スナップポイント定義中は次の点に自動的にスナップします:

-

すべての穴中心。

-

穴円周上の90°位置(直交軸と交差する点)。

-

外形線の中点。

-

モデルのボディ軸。

-

2つのスナップポイント間の線分の中心点(スペースバー・モード)。

これらのスナップポイントは、穴中心への自動スナップ機能を使用して追加されました。

これらの位置へのスナップは、3Dレイアウトモードで

Reports » Measure Distancesコマンドを使用する場合にも利用できます。

プロパティパネルでモデルの向きを調整する

モデルの向きを調整する優れた方法は、Propertiesパネルの3D Body modeを使用することです。値をキーボードから編集できるため、3Dでモデルを確認しながら、さまざまなX、Y、Z値を素早く試して向きを変更できます。キーボードは次の用途に使用できます:

-

Ctrl+F – 表示を反転する。

-

M – オブジェクトを移動する。

-

J – 設計空間内の位置へジャンプする。

-

R – JumpサブメニューからReference(PCBライブラリエディタの設計空間原点)を選択する。

-

Enter – パネルに入力した値を適用し、移動中のモデルを配置する。

これにより、各軸周りのモデル回転や、Z平面方向の上下移動(下の動画で実演)を行えます。

Propertiesパネルを使用して、モデルの向きを視覚的に再調整できます。

3D Body配置コマンドを使用する

本ソフトウェアには、3D Bodyの向きと位置を調整するためのコマンドが含まれています。

3D Bodyの向きと位置を調整

この機能では、3Dモデル表面上にある3つのアンカーポイントを選択し、次にそれぞれのスナップポイントを結合(マッチ)させるPCB上の3つの参照点を指定します。この手法では、3Dモデル上の任意の頂点を使用できるため、必ずしも事前にスナップポイントを配置しておく必要はありません。

この機能は押し出し3Dモデルでは動作しません。これは、そのモデル種別が3次元回転をサポートしていないためです。

手順は次のとおりです:

-

3Dレイアウトモードに切り替えます(ショートカット: 3)。

-

メインメニューからTools » 3D Body Placement » Orient and Position 3D Bodyコマンドを選択します。

-

ステータスバーにモデル選択が促されるので、再配置したい汎用モデルをクリックします。

-

カーソルが3D位置決めカーソル(青色の六芒星)に変わり、3Dモデル上の点を選択するよう促されます。ここで3つのアンカーを順に選択する必要があります。理想的には、事前定義されたモデル参照点や、ピン中心に配置されたスナップポイントなど、正確な基準となる点を選びます。ステータスバーには、現在どのアンカーを選択しているかが表示されます。なお、ステータスバーには、現在カーソル下にある頂点またはスナップポイントの数値参照値が表示されます。ユーザー定義スナップポイントは2以上の低い値になります。この値に注意して、正しいクリック位置の特定に役立ててください。スナップポイントの追加については、Defining Snap Pointsセクションを参照してください。

-

3つのアンカーを選択したら、次に同じ順序で、これらのアンカーを載せるフットプリント上の3つの位置を選択します。ステータスバーのガイドに従って3つの位置を選択してください。カーソルは設計空間内を移動している間は青色ですが、パッドなどのオブジェクト中心上にある場合は緑色に変わります。

-

3つ目のアンカー位置をクリックするとすぐに、ソフトウェアが3つの位置を結合しようとして、モデルの向きと位置が変更されます。その後、コマンドは終了します。

移動後、選択した3D Bodyの回転値とスタンドオフ高さがPropertiesパネルに反映されます。必要に応じてこれらを調整し、配置を微調整できます。

この手順は下の動画で実演しています。

汎用モデルの向きを再調整する手順を示す動画。

3D Bodyの位置決め

この機能は2点を使用します。まず3Dモデル上の点を1つ選択し、次に基板/フットプリント上で対応する点を1つ選択します。この手法では、3Dモデル上の任意の頂点を使用できるため、必ずしも事前にスナップポイントを配置しておく必要はありません。

このコマンドは、横方向の平行移動のみで3D Bodyを再配置する点に注意してください。2点のみを使用するため、回転は行われません。

手順は次のとおりです:

-

3Dレイアウトモードに切り替えます(ショートカット: 3)。

-

メインメニューからTools » 3D Body Placement » Position 3D Bodyコマンドを選択します。カーソルが十字カーソルに変わり、位置決めしたい3Dモデルを選択するよう促されます。

-

対象の3Dモデル上にカーソルを置いてクリックするか、Enterを押します。カーソルが3D位置決めカーソル(青色の六芒星)に変わり、3Dモデル上の点を選択するよう促されます。

- 3Dカーソルを頂点(またはスナップポイント)の上に移動し、クリックするか Enter を押して、メインのアンカーポイントを定義します。これは 3D モデルの anchor point であり、基板/フットプリントのアンカーポイントと正確に一致(交差)させるために使用されます。

-

カーソルは2つの青い円錐(選択モード)として表示されるように変わり、基板/フットプリント上の点を選択するよう促されます。

-

カーソルを目的の位置に合わせてクリックするか Enter を押し、メインアンカーポイントの移動先を定義します。これは、ボディを再配置したときに 3D モデルのメインアンカーポイントが移動する先の点です。

-

基板/フットプリントの移動先点を選択すると、それに応じて 3D モデルが再配置されます。

Set Body Height

この機能は、選択した 3D Body の高さを、基板/フットプリントの上面に対して相対的に調整するために使用します。

手順は次のとおりです:

-

3D Layout Mode に切り替えます(ショートカット: 3)。

-

メインメニューから Tools » 3D Body Placement » Set Body Height コマンドを選択します。カーソルが十字に変わり、配置したい 3D モデルを選択するよう促されます。すべての 3D モデルタイプがサポートされています。

-

対象の 3D モデル上にカーソルを合わせてクリックするか Enter を押します。カーソルが 3D 位置決めカーソル(青色の6点)に変わり、3D モデル上の点を選択するよう促されます。

-

3D カーソルを 3D モデル上の頂点(またはスナップポイント)に移動し、クリックするか Enter を押して、基板/フットプリントからの高さを設定する対象点を定義します。

-

Choose Height Above Board Top Surface ダイアログが表示されます。ここで、そのモデル上の点を Z 平面上のどこに配置するかを指定します。Board Surface 上に置くか、または 3D モデルが現在配置されている Board Side の表面から Custom の距離にするかを選びます。

-

任意の高さが必要な場合は Custom を選択し、基板/フットプリント表面に対する 3D モデル上の指定点の高さ(正または負)を入力します。

Choose Height Above Board Top Surface ダイアログ

-

OK をクリックすると、3D モデルはそれに応じて Z 平面方向に再配置されます。

Orient and Position 3D Body、Position 3D Body、Set Body Height、または Measure Distances コマンドの使用中に 3D モデル上の点の選択を求められた場合、Tab を押すと Choose Selectable Points ダイアログにアクセスできます。ここで、3D モデル上の頂点および/またはスナップポイントを、選択および測定の対象にするかどうかを選べます。

Choose Selectable Points ダイアログ

Align Face With Board

この機能は、選択した 3D Body の指定面が基板/フットプリント表面と揃うように配置するために使用します。

-

整列に使用できるのは平坦(平面)な面のみです。

-

参照される基板/フットプリント表面(上面または下面)は、選択モデルのプロパティ表示時に Properties パネルの Properties セクションにある Board Side 設定によって決まります。

手順は次のとおりです:

-

3D Layout Mode に切り替えます(ショートカット: 3)。

-

メインメニューから Tools » 3D Body Placement » Align Face With Board コマンドを選択します。カーソルが十字に変わり、整列したい 3D モデルを選択するよう促されます。

-

整列したい 3D モデル上にカーソルを合わせてクリックするか Enter を押します。モデルは半透明になります。

-

カーソルを 3D モデル上で動かして面を探します。カーソル下に平坦な面が見つかると、その面は不透明になり、薄い青色の枠線が表示されます。

-

適切な面が見つかったら、クリックするか Enter を押します。選択した面が基板/フットプリント表面と整列します。

PCB Editor 内で 3D 衝突チェックを実行

3D PCB エディタの最大の強みの1つは、3D 衝突テストを実行できることです。一般的な部品同士の衝突を検出できるだけでなく、ある部品を別の部品の下に自信を持って配置したり、読み込んだ基板が筐体に正しく収まるかをテストしたりできます。

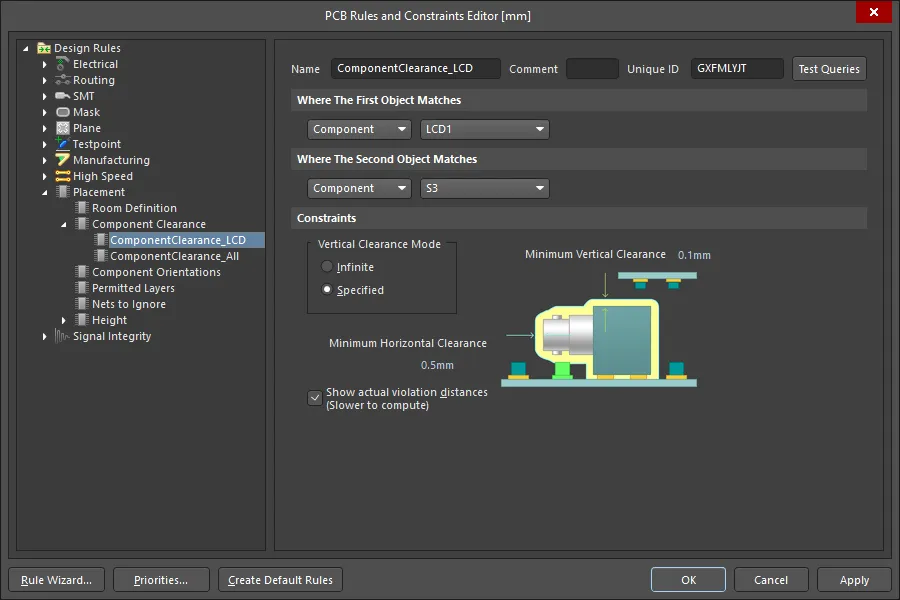

衝突テストは Component Clearance デザインルールに依存します。3D ボディオブジェクトを含む部品同士の衝突を X、Y、Z 各平面でチェックするために、Component Clearance デザインルールを追加します。これにより、ある部品が別の部品の上を通る際のクリアランスを確認できます。異なるクリアランス要件に対応するため、複数のルールを定義できます。なお、Design Rule Check は 3D ボディオブジェクトが基板を貫通しているかどうかはテストしません。

これは二値ルールであり、between「このオブジェクト(群)」と「そのオブジェクト(群)」をテストします。

衝突テスト処理を精密に制御するために、複数の Component Clearance デザインルールを定義できます。

既定の動作では、違反しているオブジェクトと、それら2つのオブジェクト間距離が表示されます。オブジェクト間の最小離隔の正確な位置を確認するには、Component Clearance デザインルールで Show actual violation distances オプションを有効にします。

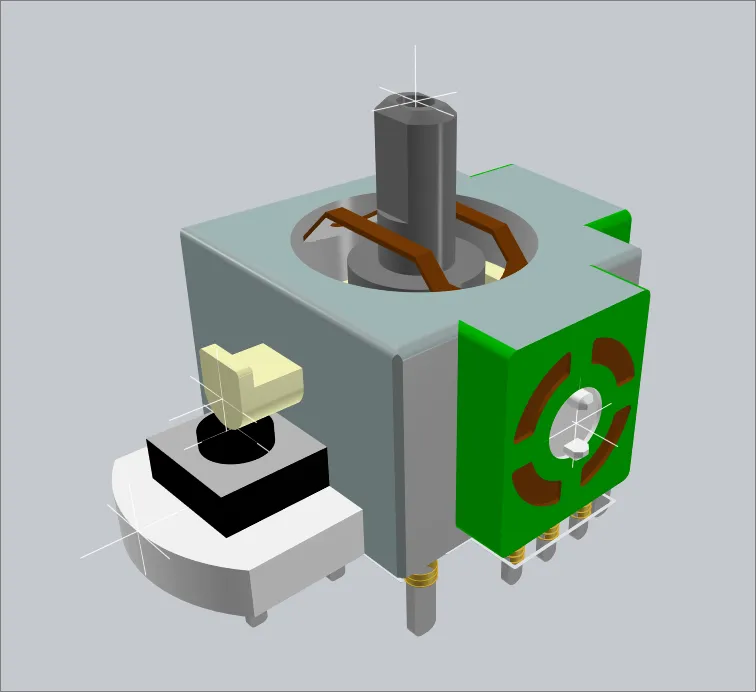

衝突は作業中に検出されます。このアニメーションで適用されているルールは前の画像に示したもので、プッシュボタンのボディが LCD の下に収まることを許可しています。

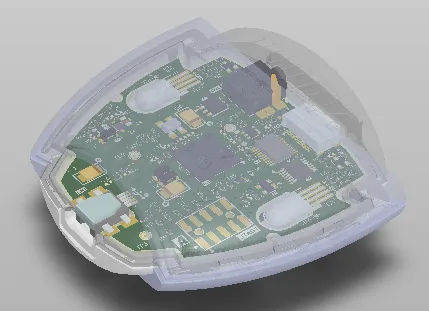

製品ケースをインポートすることもでき、3D クリアランスチェックを実行できます(下の画像にカーソルを合わせてください)。

リジッドフレックス設計では、基板を対話的に折り曲げられるため、実装状態での基板クリアランスチェックに最適です。

デザインルールで 3D モデルを参照する

デザインルールシステムを最大限に活用するには、デザインルールのスコープを最適に設定する方法を理解することが重要です。ルールスコープは、そのルールが対象とするオブジェクト集合を定義します。たとえば InPolygon キーワードでスコープしたルールは、基板上のすべてのポリゴン内にあるすべてのプリミティブに適用されます。特定のポリゴン内のオブジェクトを対象にするには、InNamedPolygon('PolygonNameHere') キーワードを使用します。

特定のコンポーネントを対象にするルールを作成する場合は、クエリキーワード InComponent('ComponentDesignatorHere') を使用できます。そのルールスコープは、パッド、オーバーレイトラック、3D モデルなどを含む、コンポーネント C1 内のすべてのオブジェクトを対象にします。

コンポーネント内の 3D モデルだけをルール対象にしたい場合は、デザインルールで id キーワードを使用できます。たとえば上の動画では、LCD は LCD1 というデジグネータを持つ独立したサブアセンブリです。そのコンポーネントで使用されている 3D モデルの id 値は、下の最初の画像に示すとおり LCD_2x16 です。この id を使用するには、下の2番目の画像に示すようにルールを設定できます。

3D Body Identifier を使用してデザインルールのスコープを設定すると、コンポーネントの 3D モデルのみを対象にできます。

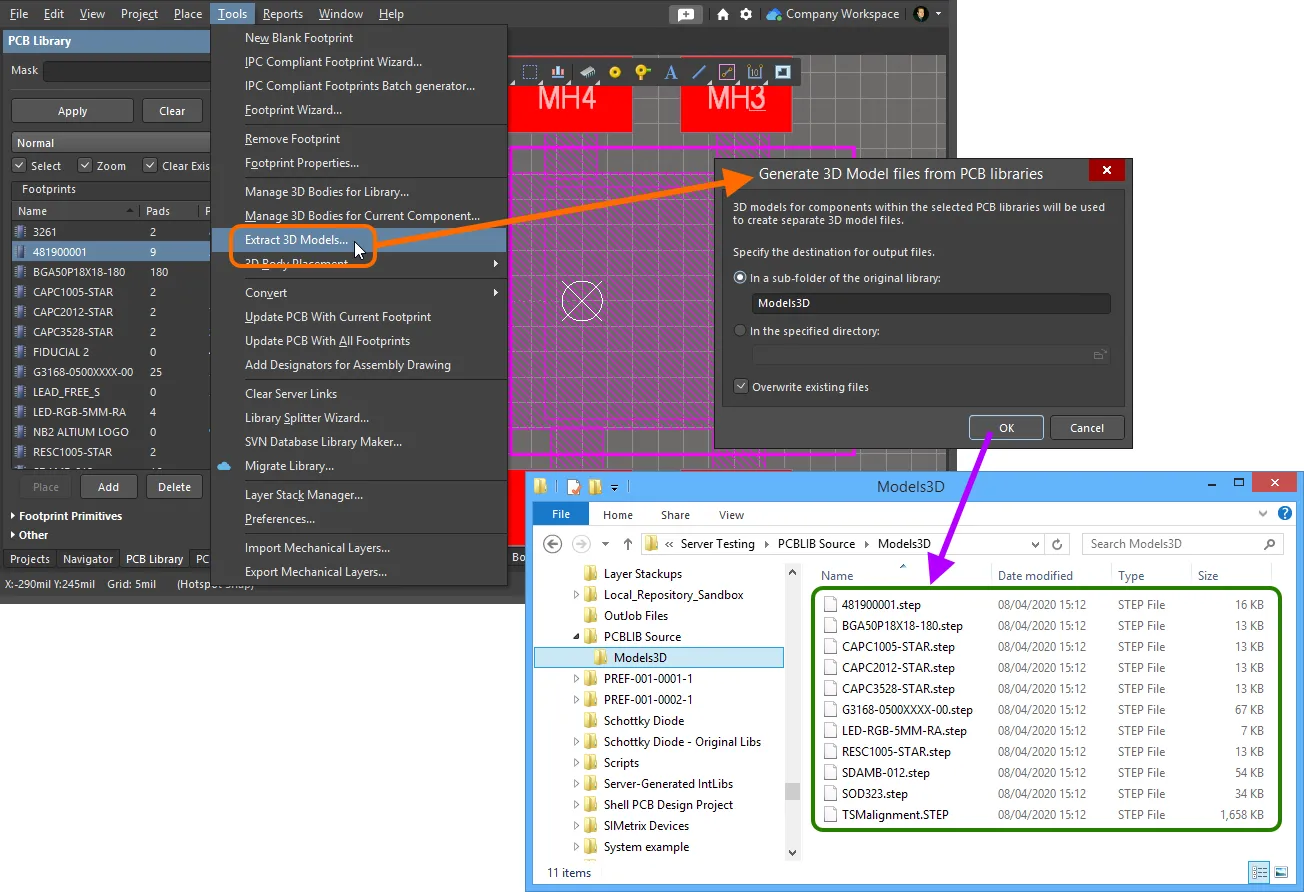

PCB ライブラリから 3D モデルを抽出する

PCB Library ドキュメント(*.PcbLib)内の 2D フットプリントモデルに 3D モデル(STEP、Parasolid®、SOLIDWORKS®)が埋め込まれている場合、PCB フットプリントエディタにはそれらのモデルを抽出するユーティリティが用意されています。手順は次のとおりです:

-

3D モデルを抽出したい PCB Library を開きます。

-

メインメニューから Tools » Extract 3D Models コマンドを選択します。

-

表示される Generate 3D Model Files from PCB Libraries ダイアログで、生成ファイルの保存先を指定します。ソース PCB Library のある場所のサブフォルダ(Specify the destination for output files オプション)にするか、別の場所の指定フォルダ(In the specified dicrectory オプション)にします。指定フォルダが存在する場合はそれが使用され、存在しない場合は作成されます。(

) を選択して、出力ファイルを配置したいディレクトリを指定します。

) を選択して、出力ファイルを配置したいディレクトリを指定します。

-

必要に応じて Overwrite existing files を選択し、新しいファイル生成時に同名の既存 3D モデルファイルを上書きするようにします。

-

必要なオプションを定義したら OK をクリックします。生成が実行され、完了すると確認ダイアログが表示され、生成された 3D モデルファイル数が示されます。

各 3D モデルファイルは、2D フットプリントモデル名を使用して命名されます。

-

抽出できるのは埋め込み 3D モデルのみです(押し出し、円柱、球は対象外)。

-

3D モデルを抽出できるのはファイルベースの PCB ライブラリ(

*.PcbLib)からのみで、Workspace フットプリントからは抽出できません。

抽出ツールを使用して PCB Library から生成された 3D モデルファイルの例。

接続された Workspace への 3D モデルのアップロード

Altium Designer は、接続された Workspace と組み合わせることで、Workspace 3D Models の作成と管理に対応します。ファイルベースのリンク 3D モデルと同様に使用でき、Workspace 3D Model は 3D モデルファイルを保持し、それが標準の 2D フットプリントに付加された 3D ボディを介して referenced through a 3D body されます。

適用するモデルファイルをアップロードすることで、3D Model Item の新しいリビジョンを作成できます。これはいくつかの方法で実行できます。詳細は Uploading Data into a New Revision of an Item を参照してください。

アップロードするモデルファイルでサポートされている形式は次のとおりです。

-

STEPファイル(

*.step、*.stp)

-

Parasolidファイル(

*.x_t、*.x_b)

-

SolidWorks部品ファイル(

*.sldprt)

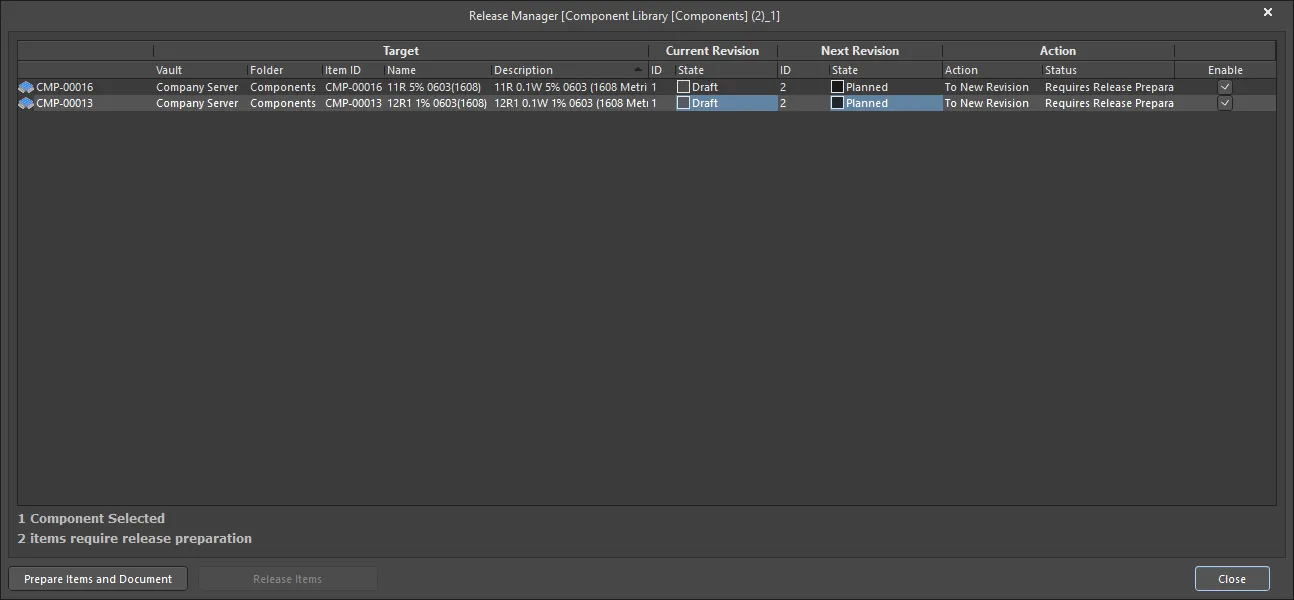

Windowsエクスプローラーからドラッグ&ドロップ操作で複数の3Dモデルファイルを Explorer パネルにアップロードする場合、 Release Manager ダイアログが開くことに注意してください。

Release Manager ダイアログ

Options and Controls of the Release Manager Dialog

グリッド領域

グリッドには、アイテムとボールトベースのItemとのリンクに関するすべての情報、およびソースエンティティがリリースプロセスに含まれる場合に実行されるアクションが表示されます。次の情報が表示されます。

-

Component - リリース対象のコンポーネント。

-

Target - すでに確立されている(すでにリリース済みの場合)または確立される予定(初回リリース待ちの場合)の、Itemへのリンクに関する情報を提供します。これは、対象の Vault、そのボールト内の Folder、およびItem自体の Item ID、Name 、Description で構成されます。

-

Current Revision - アイテムが以前にリリースされている場合、この領域には最新のリリース済みリビジョンに関する情報が表示されます。リビジョン ID とライフサイクル State が含まれます。

-

Next Revision - 後続のリリースでアイテムからのデータを受け取るために作成される、次のアイテムリビジョンに関する情報を提供します。リビジョン ID と、そのリビジョンのライフサイクル State が含まれます。新規リリースの場合、これは常に

Planned 状態になります。

-

Action - リリースプロセスの一部として、この特定のアイテムに対してRelease Managerが実行する Action を表示します。まだリリースされていないエンティティの場合、この項目には

To New Revision が表示されます。関連する Status フィールドは、プロセスで次に実行されるステップ(例: Requires Release Preparation)を示すために使用され、リリースプロセス完了後は結果を反映します。

-

Enable - このチェックボックスは、アイテムをリリースプロセスに含める(チェック)か、プロセスから除外する(未チェック)かを制御します。

-

xx Component(s) Selected - ダイアログで選択されているアイテム数を表示します。

-

xx Items require release preparation - リリース前にリリース準備が必要なアイテム数を表示します。

-

Prepare Items and Document - クリックすると、リリースされるエンティティのドキュメントと対応するアイテムを準備します。

-

Release Items - アイテムのリリース準備が完了すると、 Release Items ボタンが使用可能になり、リリースを続行するよう促されます。リリースしたくないアイテムがあることに気付いた場合は、この時点で関連する Enable チェックボックスのチェックを外してください。

-

ドキュメントの準備後、リリースする前に Release Manager を閉じようとすると、警告ダイアログが表示されます。準備フェーズの一部としてソースライブラリドキュメントに書き込まれた、新しいターゲットアイテムリビジョンへのリンクが無効になることが警告されます。この段階ではリリースを続行することを強く推奨します。

-

選択した3Dモデルのリリースに要した時間は Output パネルに表示されます。

3Dワークスペースモデルの更新

Workspace 3D Modelに保存されている3Dモデルを変更する必要がある場合は、必要な新しいモデルをそのWorkspace 3D Modelにアップロードしてください。新しいモデルは、そのWorkspace 3D Modelの次のリビジョンに保存されます。

関連フットプリントの更新

3Dモデルに変更を加え、その変更をWorkspace 3D Modelの新しいリビジョンにアップロードした瞬間、そのモデルを使用しているWorkspace Footprintは、以前のリビジョンを使用したまま実質的に古い状態になります。多くの場合、利用可能な最新リビジョンを使用するように各モデルリンクを更新して、それらのWorkspace Footprintを再保存したいはずです。このプロセスを効率化するために、WorkspaceはAltium Designerと連携し、3Dモデルの最新リビジョンへのアップロード時点で関連フットプリントを更新できる機能を提供します。

アップロード後、現在その3Dモデルを参照しているフットプリントがある場合、それらのWorkspace Footprintを更新するかどうかを尋ねるダイアログが表示されます。

関連するすべてのWorkspace Footprintで3Dモデルの現行リビジョンを使用し続けたい場合は、ダイアログで No をクリックします。その場合、モデル自体のみがアップロードされます。

その後、PCBフットプリント ドキュメントが、関連付けられた一時エディタ(直接編集用)で開かれます。複数のフットプリントが3Dモデルを使用している場合、PCBフットプリントが個別に複数開かれるのではなく、影響を受けるすべてのPCB 2D/3Dコンポーネントモデルを含むドキュメントが表示されます。

参照されている3Dモデルのリビジョンは自動的に最新へ更新されません。必要に応じて、

Propertiesパネル から手動で更新する必要があります。

モデルの3Dボディが(必要に応じて)Workspace 3D Modelの最新リビジョンを参照するよう更新されたら、メインメニューから Save to Server コマンド(ショートカット:Ctrl+Alt+S)を選択して、変更したモデルをターゲットWorkspace内の対応するWorkspace Footprintの新しいリビジョンとして保存します。

Workspace Footprintの再保存の一環として、親コンポーネントも更新する機会があります。更新オプションを有効のままにしておけば、これは自動的に実行されます。

PCB設計で使用されている3Dボディの参照

PCBパネルの 3D Models モードでは、3つの主要領域が、現在のPCB設計の3Dボディ階層(上から順)を反映するように変化します。

-

Component Classes

-

3Dボディオブジェクトまたはフリーモデル(PCBに実装されない、自由に配置された3Dボディ)に関連付けられているコンポーネントクラスに関連する特定の Components

-

各コンポーネントまたはフリー Models

Components パネル領域でコンポーネント項目をダブルクリック(または右クリックして Properties を選択)すると、PropertiesパネルのComponentモード が開き、詳細にプロパティを編集できます。同様に、Models パネル領域でモデル項目をダブルクリック(または右クリックして Properties を選択)すると、Propertiesパネルの3D Bodyモード が開き、3Dボディのプロパティ一式を編集できます。

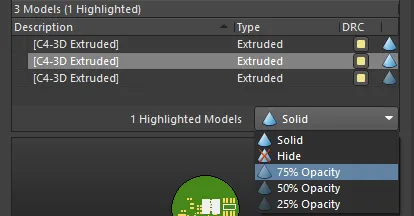

PCB パネルは、3Dモデルの表示プロパティを選択するために使用できます。  アイコンは、100%(非表示)から0%(不透明)までを25%刻みで表した、異なる透明度レベルを示します。Highlighted Models オプションを使用すると、複数のコンポーネントを選択して同じ表示制御を一括適用できます。

アイコンは、100%(非表示)から0%(不透明)までを25%刻みで表した、異なる透明度レベルを示します。Highlighted Models オプションを使用すると、複数のコンポーネントを選択して同じ表示制御を一括適用できます。

アイコンは、STEPモデルを含む3Dオブジェクトタイプの Design Rule Checking を有効または無効にするために使用できます。このアイコンは、1回クリックでチェック解除(無効化)、2回クリックでチェック(有効化)できます。

アイコンは、STEPモデルを含む3Dオブジェクトタイプの Design Rule Checking を有効または無効にするために使用できます。このアイコンは、1回クリックでチェック解除(無効化)、2回クリックでチェック(有効化)できます。

選択したモデルが 75% Opacity に設定されます。複数のモデルを選択して一度に変更することもできます。