After launching the command, the cursor will change to a crosshair and you will enter track placement mode. Placement is made by performing the following sequence of actions:

Placement Modes

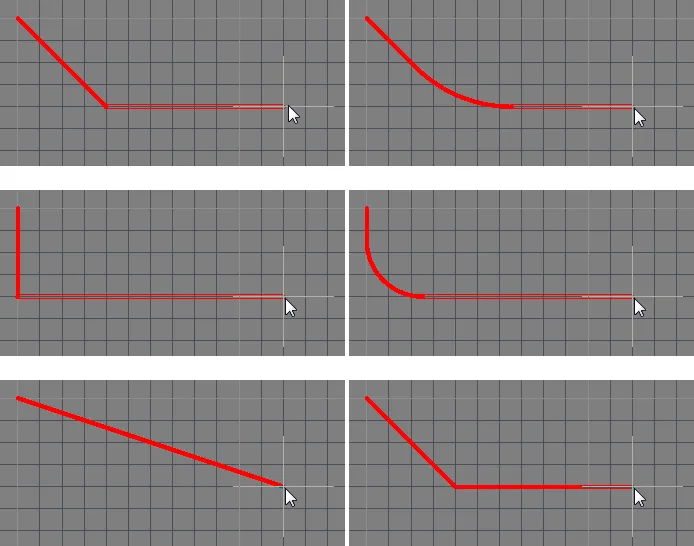

While placing track segments there are five available corner modes, four of which also have corner direction sub-modes. During placement:

- Press Shift+Spacebar to cycle through the five available corner modes.

- Press Spacebar to toggle between the two corner direction sub-modes.

- When in either of the arc corner modes, hold the "," or "." key to shrink or grow the arc. Hold the Shift key as you press to accelerate arc resizing.

- Press the 1 shortcut key to toggle between placing one segment per click (shown in the first five images below), or two segments per click (shown in the last image below). In the first mode, the hollow track segment is referred to as the look-ahead segment.

- Press the Backspace key to remove the last vertex.

Interactive Routing and the Applicable Design Rules

During Interactive Routing, the default behavior is for the software to ensure the track segments are placed in accordance with the applicable Electrical and Routing design rules. That means the software will not allow a new track segment to be placed that violates an existing track segment that belongs to a different net; instead, it will clip the track segment to meet the design rules. This interactive routing behavior is known as the Routing Conflict Resolution mode. The default mode is Stop at First Obstacle (the current mode is displayed on the Status bar). Press Shift+R to cycle through the available modes.

The term applicable design rules means all the rules that apply to the object being placed. The design rules engine works on a system where you scope exactly to which objects you want each rule to apply. During placement, the design rules engine is queried to determine the highest priority rule that applies in the current placement situation.

How the Routing Width is Determined

Unless the rules engine is disabled, the overriding behavior of the software is to always ensure that the routing width is within the range allowed by the applicable Routing Width design rule. A common approach is to allow a range of widths to be used for a net to give you flexibility in fitting in the route while satisfying the current carrying requirements of that net. Supporting this, the Routing Width design rule has Min, Preferred, and Max settings in the PCB Rules and Constraints Editor that can be configured to allow a range of widths or can be set the same to require a specific width. The width can also be configured as an Impedance and can also have a different range specified for each signal layer.

Options that can help select the most appropriate routing width when you begin routing are configured on the PCB Editor — Interactive Routing page of the System Preferences.

You can also use the Shift+W shortcut while routing to access a dialog where a different width can be selected, or you can press Tab to open the Inspector panel and type in a new Width value. The value chosen or entered must lie between the Min and Max settings defined in the applicable rule. If not, it is automatically clipped back to the nearest of these.

Interactive Routing Shortcuts

While you are routing, there are a number of shortcuts that are available. For example, you can press Shift+R to cycle through the available conflict resolution modes, or press Backspace to delete the last placed vertex (corner). To display a list of shortcuts while you are routing, press Shift+F1. A menu of available interactive shortcuts is displayed; select the required shortcut or press Esc to close the menu and use the shortcut key sequence.

Graphical Editing

This method of editing allows you to select a placed line object directly in the design space and change its size, shape, or location graphically.

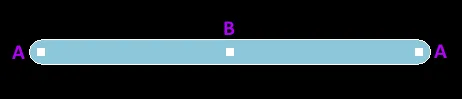

When a line object is selected, the following editing handles are available:

A selected Track

- Click and drag A to reposition the end points of the track.

- Click and drag B to change the shape of the track.

The PCB editor includes sophisticated algorithms for moving track segments on the board so that the arrangement of the routing can be maintained. This sliding of track segments can be invoked interactively either by clicking to first select the track segment and then clicking and holding when the special cursor appears to slide the segment or by clicking and holding on a track segment and sliding it.

To clear the selection of (or de-select) the object, use the Esc key.

Non-Graphical Editing

This method of editing uses the Inspector panel mode to modify the properties of a line object.

During placement, the Track mode of the Inspector panel can be accessed by pressing the Tab key. Once the line is placed, all options appear.

After placement, the Track mode of the Inspector panel can be accessed in one of the following ways:

- If the Inspector panel is already open, select the track object.

- Right-click on a selected track and select Properties from the menu.

- From the PCB editor, choose View | PCB | Inspector from the main ribbons when a track is selected.

- From the PCB library editor, choose View | PCB Library | Inspector from the main ribbons when a track is selected.