PCBレイアウトのための電気設計ルールの種類

Altium Essentials: PCB Design Rules Creation

This content is part of the official Altium Professional Training Program. For full courses, materials and certification, visit Altium Training.

Electricalカテゴリのデザインルールは以下のとおりです。

デザインルールのElectricalカテゴリ。

クリアランス

デフォルトルール:必須

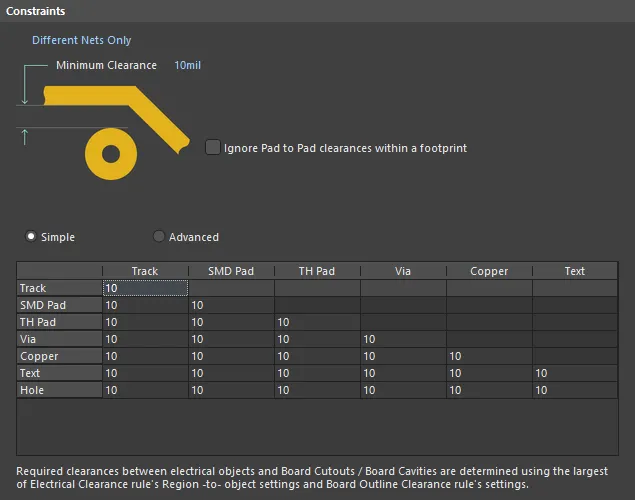

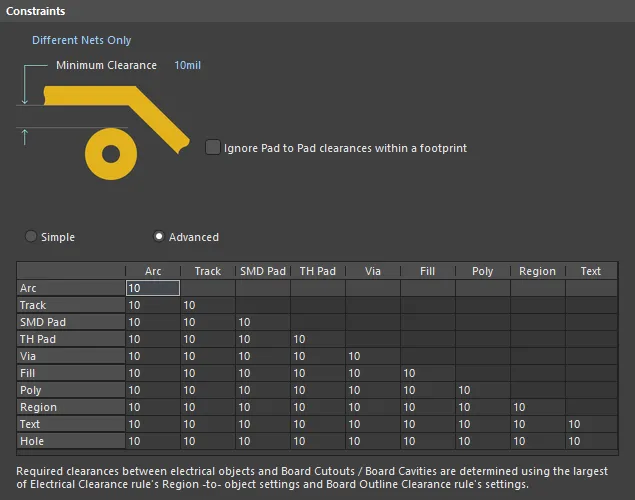

このルールは、銅層上の任意の2つのプリミティブオブジェクト間に許容される最小クリアランスを定義します。クリアランスは単一の値として指定することも、専用のMinimum Clearance Matrixを使用してオブジェクトの組み合わせごとに異なるクリアランスを指定することもできます。後者はルールスコープと組み合わせることで、最も厳しいクリアランス要件にも対応できる、簡潔で的を絞ったクリアランスルールのセットを柔軟に構築できます。

制約

ルールスコープはオブジェクトのセットを返し、以下に示す制約がそのオブジェクトセットに適用されます:

-

Connective Checking - ルールスコープが返すネットオブジェクトのセットは、さらに次の方法で絞り込むことができます:

-

Different Nets Only- 異なるネットに属する任意の2つのプリミティブオブジェクト間に制約を適用します(例:異なる2つのネット上の2本の配線)。 -

Same Net Only- 同一ネットに属する任意の2つのプリミティブオブジェクト間に制約を適用します(例:同一ネット上のビアとパッド間、または同一ネット内の2つの配線セグメント間)。 -

Any Net- 設計内の任意のネットに属する任意の2つのプリミティブオブジェクト間に制約を適用します。これは3つの選択肢の中で最も包括的で、同一ネット/異なるネットのいずれの場合も対象になります。 - Different Differential Pair - 異なる差動ペアに属する異なるネット同士の任意の2つのプリミティブオブジェクト間に制約を適用します(例:DiffPair1の配線とDiffPair2の配線)。同一差動ペア内の2つのネット間(例:DiffPair1_PとDiffPair1_N)にはルールは適用されません。この制約を使用して、差動ペア同士のクリアランスを設定します。

-

Same Differential Pair - 同一差動ペア内の異なるネットに属する任意の2つのプリミティブオブジェクト間に制約を適用します(例:TX_Pの配線とTX_Nの配線)。差動ペア内のネット同士を一般クリアランスで許容されるよりも近づける必要がある場合のクリアランス設定に使用します。

-

- Ignore Pad to Pad Clearances within a footprint - 同一コンポーネントフットプリント内のパッド間クリアランスを無視するかどうかを指定するため、このオプションをオン/オフします。このオプションはデフォルトで無効です。

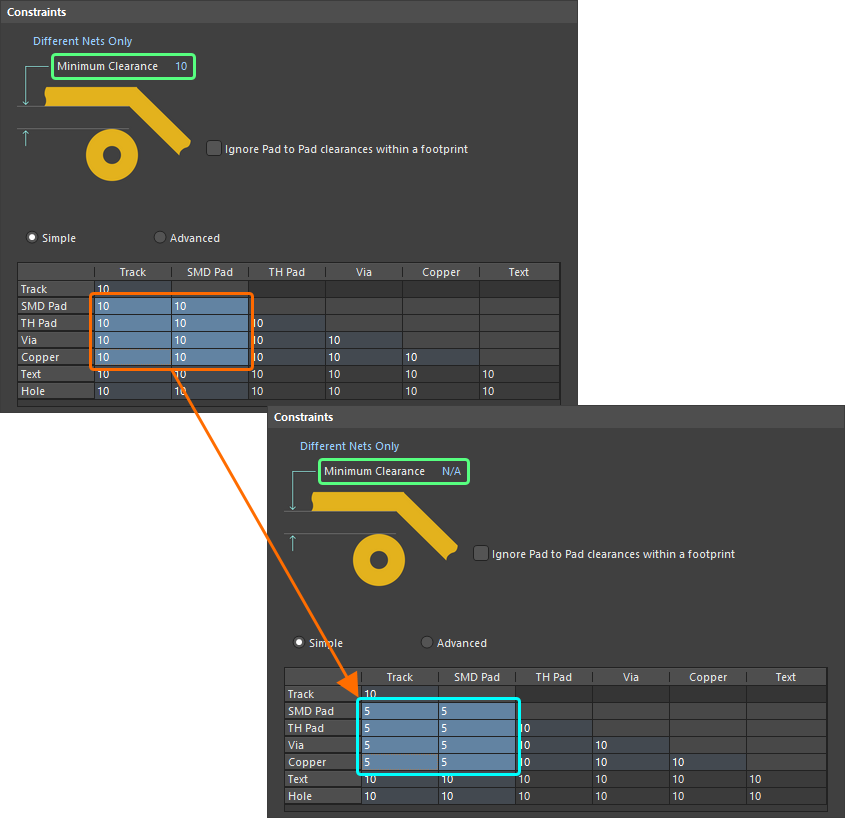

- Minimum Clearance - 必要な最小クリアランス値。この欄に入力した値は、最小クリアランスマトリクスのすべてのセルに複製されます。逆に、マトリクス内で1つ以上のオブジェクト組み合わせに別のクリアランス値を入力すると、Minimum Clearance制約はN/Aに変わり、単一のクリアランス値が一律適用されていないことを反映します。

- Minimum Clearance Matrix - 設計内の各種オブジェクト間クリアランスの組み合わせについて、クリアランスを微調整する機能を提供します。

クリアランスマトリクスの操作

多くのユーザーにとって、Track と Arc のプリミティブに大きな違いはありません。また、Fill、Region、Polygon オブジェクトについても、多くのユーザーはこれらを単に「銅」として捉えています。これを踏まえ、クリアランスルールの最小クリアランスマトリクスは、2つのモードで動作するよう拡張されました:

- Simple - このモードでは、Track と Arc オブジェクト(Track Keepout および Arc Keepout オブジェクトを含む)が単一のTrackエントリに統合されます。Fill、Poly、Region オブジェクト(Fill Keepout および Region Keepout オブジェクトを含む)は単一のCopperエントリに統合されます。Simpleモードは、既存設計を開く場合でも新規設計の場合でも、デフォルトモードです。

- Advanced - このモードは従来のマトリクスで、すべてのオブジェクトが表示されます。

マトリクス内のクリアランス値は、次の方法で定義できます:

- 単一セル編集 - 特定のオブジェクト組み合わせの最小クリアランスを変更します。セルをクリックして編集対象として選択します。

-

複数セル編集 - 複数のオブジェクト組み合わせの最小クリアランスを変更します:

- Ctrl+Click、Shift+Click、Click+Dragを使用して、列内の複数セルを選択します。

- Shift+Click、Click+Dragを使用して、行内の連続する複数セルを選択します。

- Click+Dragを使用して、複数の行と列にまたがる連続する複数セルを選択します。

- 行ヘッダーをクリックして、その行のすべてのセルを素早く選択します。

- 列ヘッダーをクリックして、その列のすべてのセルを素早く選択します。

必要な選択(単一セルまたは複数セル)を行ったら、現在の値を変更するには必要な新しい値を入力するだけです。入力した新しい値を確定するには、別のセルをクリックするか、Enterを押します。選択範囲内のすべてのセルが新しい値に更新されます。

複数セル編集の例。1つ以上のオブジェクト組み合わせに対して異なるクリアランス値が存在するようになったため、Minimum Clearance制約がN/Aに変わり、すべてのオブジェクト間クリアランスの組み合わせに単一のクリアランス値が適用されなくなったことを反映している点に注意してください。

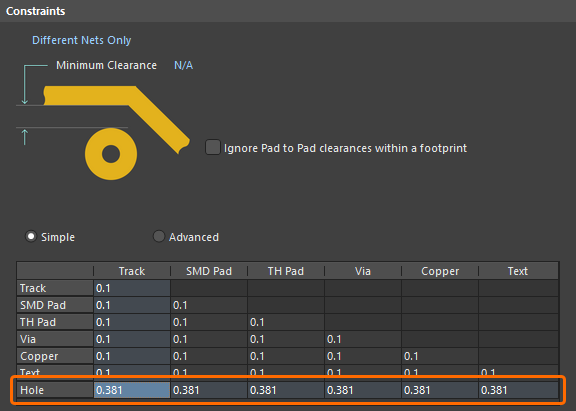

穴-オブジェクト間クリアランスチェック

設計者は、ドリル穴のエッジと信号層上の近傍の銅オブジェクトとのクリアランスをチェックできます。これは、基板製造時のドリルのぶれによって問題が生じ得る、ドリル穴に近すぎる配線のルーティングを防ぐうえで特に有効です。クリアランスルールの最小クリアランスマトリクスの最下段の行は、望ましいクリアランスを定義するために使用されます。

設計内でドリル穴のエッジに近すぎる銅オブジェクトを検出できるよう、クリアランス値を設定します。

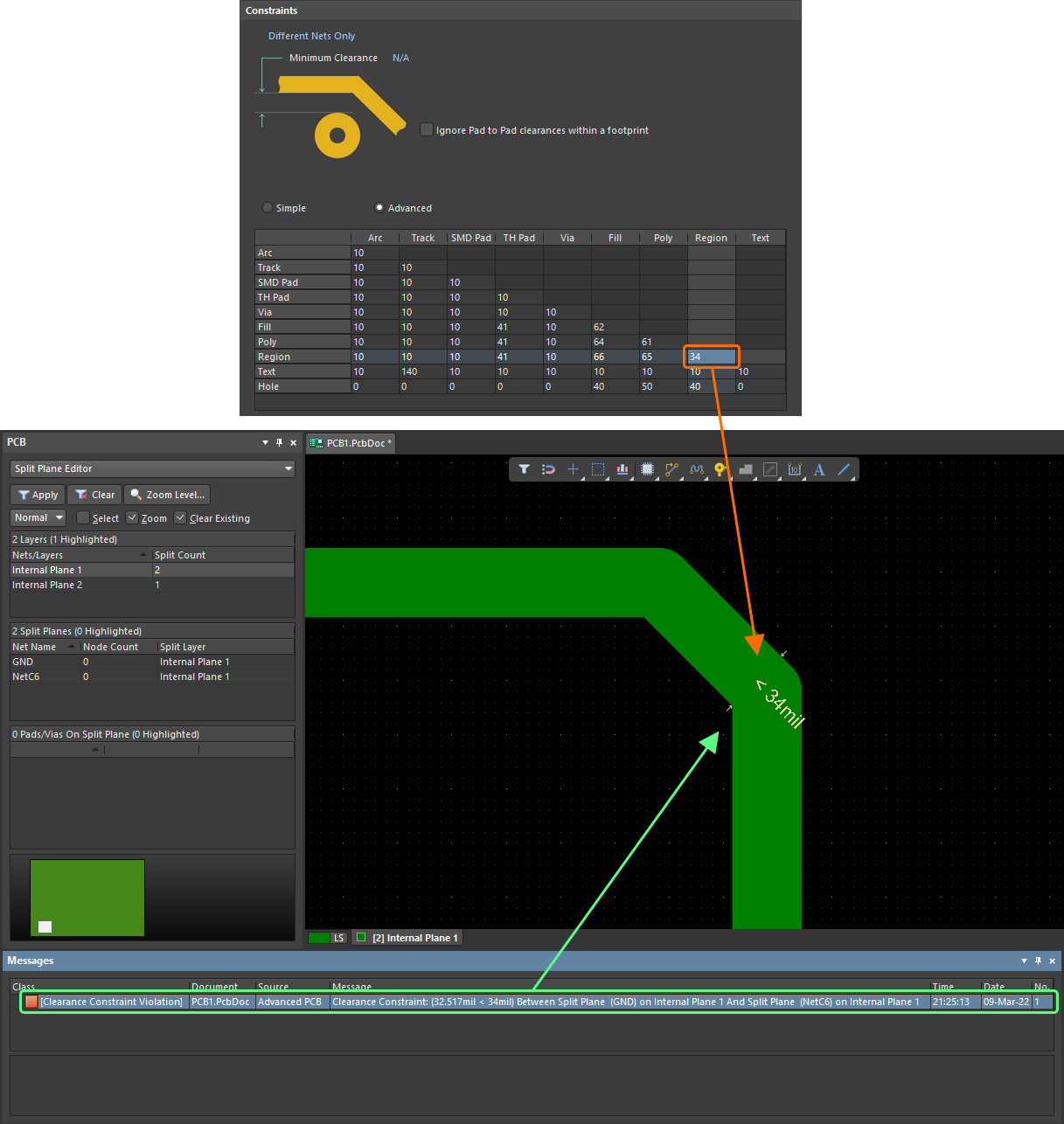

スプリットプレーンのクリアランスチェック

設計者は、内部プレーンレイヤー上のスプリットプレーン領域間のクリアランスもチェックできます。クリアランスの定義方法は、最小クリアランスマトリクスを使用しているモードによって異なります。

- Simple mode - Copper-Copper セルを使用して、必要なスプリットプレーン間クリアランス値を指定します。

- Advanced mode - Region-Region セルを使用して、必要なスプリットプレーン間クリアランス値を指定します。

違反は次の形式で表示されます。

Clearance Constraint: (<CurrentClearance> < <DefinedClearance>) Between Split Plane (<NetName>) on <InternalPlaneLayerName> And Split Plane (<NetName>) on <InternalPlaneLayerName>、

例:

Clearance Constraint: (32.36mil < 34mil) Between Split Plane (GND) on Internal Plane 1 And Split Plane (NetC6) on Internal Plane 1

内部レイヤー上のスプリットプレーン領域間のクリアランスチェック。この場合、マトリクスの Advanced モードを使用してクリアランスを定義しているため、Region-Region セルに 34mil のクリアランス値が入力されています。

差動ペアのクリアランスチェック

差動ペアには固有の設計上の課題があり、多くの場合、特定の within-pair クリアランスに加えて pair-to-pair クリアランス、さらに pair-to-all other nets クリアランスを制御するための第 3 のルールが必要になる可能性があります。これをサポートするため、Constraints 領域には Same Differential Pair および Different Differential Pair オプションを選択できるドロップダウンが含まれています。

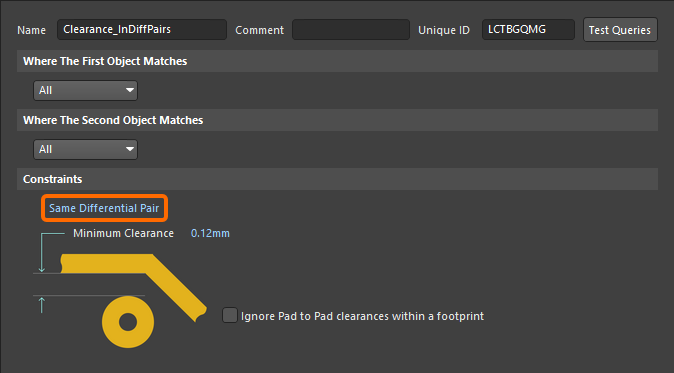

たとえば、差動ペア内のネットが一般的な基板クリアランスよりも厳しいクリアランスを必要とする場合、以下に示すように Same Differential Pair 制約オプションを使用して実現できます。ルールスコープは設計内の All ネットオブジェクトに適用されますが、Constraint 設定により Same Differential Pair 内のオブジェクトにのみ適用されるよう制限される点に注意してください。

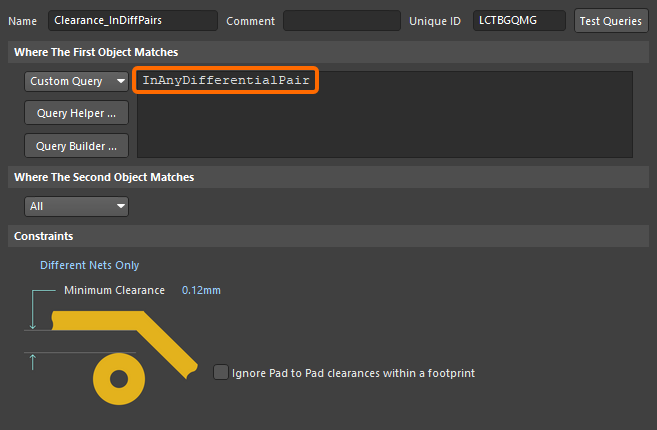

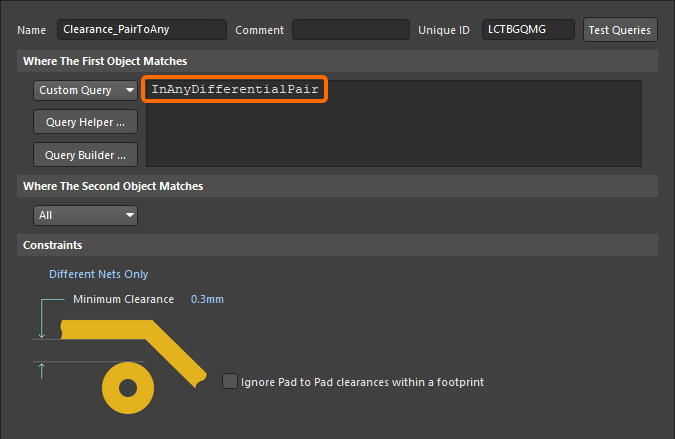

この結果は、以下に示すように、ルールが差動ペアオブジェクト(例:InAnyDifferentialPair)にのみ適用されるようスコープ設定することでも実現できます。ただし、このルールは差動ペア内のネットと、設計内の他の任意のネットオブジェクトとの間にも適用されます。そのため、この方法は、DiffPairNet-to-DiffPairNet および/または DiffPairNet-to-Any 要件を定義する他の優先度の高いルールがある場合にのみ使用してください。この方法を使用する場合、差動ペアルールの Priority も正しく設定する必要があり、より厳しいクリアランス要件を持つルールの優先度を高くしてください。

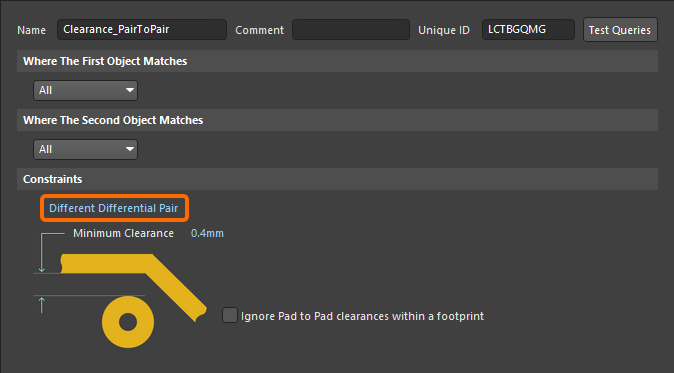

同様のアプローチで、差動ペア between のクリアランスを制御できます。以下の画像は、Different Differential Pair 制約を使用してこれを実現する方法を示しています。

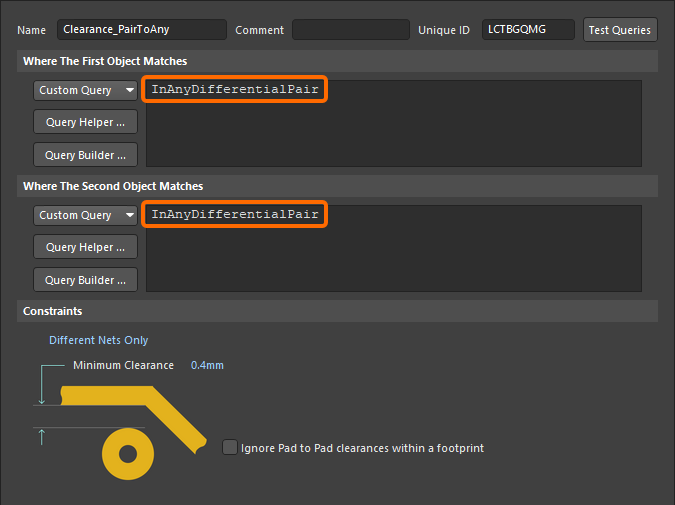

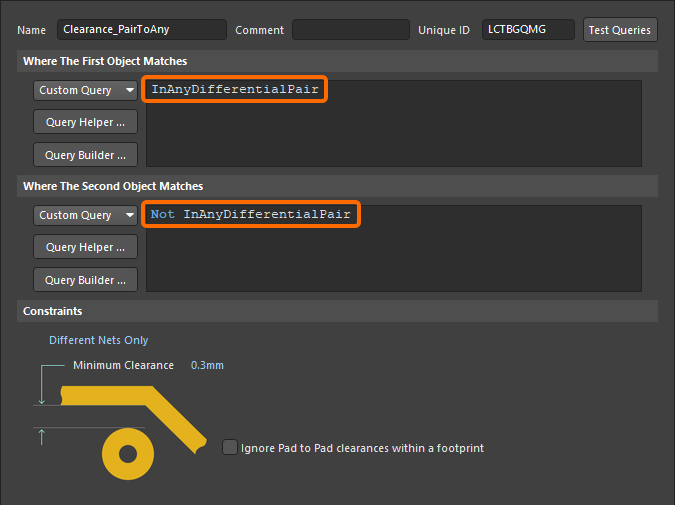

前の例と同様に、Different Differential Pairs 制約の代わりにルールスコープを使用して実現することもできます。より厳しいクリアランス要件を持つルールの優先度が高くなるよう、ルール優先度を設定する必要があることを忘れないでください。

差動ペアのネットから他の任意のネットオブジェクトへのクリアランスを別の値で定義するには、次のルールを使用できます。

これは、以下に示すように、差動ペアオブジェクトと非差動ペアオブジェクトの間にのみ適用されるよう、さらに絞り込むこともできます。

差動ペア配線 について詳しく学ぶ。差動ペア設計ルール のスコープ設定について詳しく学ぶ。

ルールの適用

Online DRC、Batch DRC、インタラクティブルーティング #、オートルーティング #、およびポリゴン配置。

注記

- # DRC は、どのようなルールスコープでも、任意の種類のオブジェクト同士のクリアランスをテストできますが、ルーティングエンジンはこの粒度の細かさをサポートしていません。たとえば、基本のクリアランスルールで全トラックのクリアランスを 1 mm とし、より優先度の高いルールで長さ 10 mm を超えるトラックのクリアランスを 2 mm と要求している場合、インタラクティブルーティングエンジンは基本クリアランスルールに従い、優先度の高い「長さ 10 mm 超」のルールは無視します。別の例として、コーナーでアークを用いた配線があります。クリアランスルールがトラックよりアークに対して大きいクリアランスを指定しており、コーナーでアークを使ってインタラクティブに配線している場合、インタラクティブルーティングエンジンはアーク設定を無視してトラック設定に従い、コーナーのアークをトラックセグメントと同じクリアランスで配置します。これら 2 つの例では、配線が完了するとすぐに Online DRC がそれらの状況を違反としてフラグします。

-

ルールの制約を定義する際、Connective Checking オプションは通常

Different Nets Onlyに設定します。Same Net OnlyまたはAny Netを使用できる例としては、同一ネット上、または別ネット上のパッドや他のビアに対して、ビアが近すぎる位置に配置されていないかをテストする場合などがあります。 - 最小クリアランスマトリクスは、指定された接続チェック方法に関係なく適用されます。同一ネット上のオブジェクト間で、異なるネット上のオブジェクト間に定義したものとは異なるクリアランスが必要な場合は、必要に応じて別のクリアランスルールを定義してください。

- クリアランスマトリクスの適用範囲は、ルールスコープに依存します。たとえば、スコープが ALL-ALL の場合、マトリクス内のすべてのセルが適用対象になります(つまり、考えられるすべてのオブジェクトの組み合わせ)。しかし、スコープが IsVia-IsTrack に設定されている場合、適用されるのは Via-Track のオブジェクト組み合わせに対応する単一セルのみで、マトリクス内の他のセルは未使用のままになります。

-

ポリゴンに対してクリアランスルールを定義する場合、ルールが実際に適用されるのはポリゴンそのものではなく、ポリゴンを構成するプリミティブです。この場合、Full Query には

IsPolygon(またはIsPoly)ではなく、キーワードエントリInPolygon(またはInPoly)を含める必要があります。特定のポリゴンクリアランスルールを有効にするには、一般的なクリアランスルールよりも高い優先度を与える必要もあります。 - 配線(および同様の操作)中、ルールエンジンは編集点の周囲にある障害物を常にチェックします。スキャンされる領域には、プリミティブの領域に加えて、そのプリミティブの周囲に必要なクリアランス領域が含まれます。つまり、ルールで定義したクリアランスが大きいほどスキャンすべき領域も大きくなり、その結果、動作は遅くなります。大きなクリアランスが必要なのが少数のオブジェクトだけであれば、それらに対して大きなクリアランスルールを定義する代わりに、該当オブジェクトの周囲にキープアウトを追加することで、配線エンジンの低速化を回避できます。

- Dielectric Shapes Generator (Printed Electronics)をAuto モードで使用する場合、誘電体シェイプは、適用される Clearance Constraint デザインルールの要件を満たすように自動的に拡張されます。

- Printed Electronicsでは、ネット間クリアランスは同一レイヤーだけでなく、すべてのレイヤーでテストされます。

短絡(Short-Circuit)

デフォルトルール:必須

このルールは、銅箔(信号層およびプレーン層)上のプリミティブオブジェクト間の短絡をテストします。ネット名が異なる 2 つのオブジェクトが接触している場合、短絡が存在します。

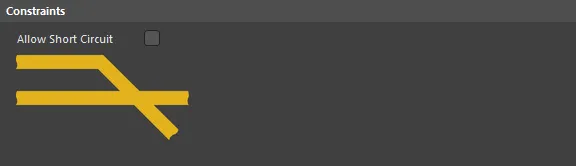

制約(Constraints)

Short-Circuit ルールのデフォルト制約

Allow Short Circuit - ルールの 2 つのスコープ(Full Query)に該当する対象ネット同士を短絡可能にするかどうかを定義します。たとえば設計内で 2 つのグランド系を接続するなど、異なるネット同士を意図的に短絡させる必要がある場合は、このオプションを有効にしてください。

ルール適用(Rule Application)

Online DRC、Batch DRC、および自動配線中。

注記(Notes)

-

Printed Electronics design では、異なるネットが異なるレイヤー上で交差すると短絡として検出されます。これらのクロスオーバーは、非導電レイヤー上に誘電体パッチを配置して絶縁します。

-

このルールは Wire Bonding にも適用されます。異なるネットのダイパッドまたは銅箔にボンドワイヤが接続されている場合、または異なるネットのボンドワイヤ同士の端点が接続されている場合に違反となります。

未配線ネット(Un-Routed Net)

デフォルトルール:必須

このルールは、ルールのスコープ(Full Query)に該当する各ネットの完了状態をテストします。ネットが未完了の場合、完了している各セクション(サブネット)が配線完了率とともに一覧表示されます。配線完了は次のように定義されます。

(connections complete / total number of connections) x 100

PCB エディタの Design Rule Checking システムは通常、ネット内のすべてのノード(コンポーネントパッド)が、ネット認識の設計オブジェクト(トラック、アーク、パッド、ビア、ポリゴン)によって接続されていれば、そのネットは配線済みであると見なします。これらのオブジェクトは互いに接触していれば接続されていると見なされます。しかし、単に接触しているだけでもソフトウェア上は接続と認識される一方で、基板製造の段階では、こうした「接続」の一部は脆弱で重大な問題を引き起こす可能性があります。特に、たとえば連続する 2 つのトラックセグメント、あるいはパッド/ビアに進入するトラックが、わずかに触れているだけの場合です。このような接続はしばしば「Bad Connections」「Poor Connections」「Incomplete Connections」と呼ばれます。このルールは、そのような不十分な接続をテストするように設定することもできます。

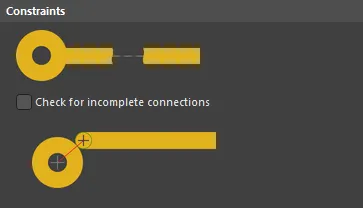

制約(Constraints)

Un-Routed Net ルールのデフォルト制約

Check for incomplete connections - このオプションを有効にすると、適用対象の設計オブジェクト間の接続性について、次の追加チェックが行われます。

- Track/Arc to Track/Arc - 接続するトラック/アークセグメントの中心線、または端点中心が一致しているかのチェック。

- Track/Arc to Via - トラック/アークセグメントの中心線、または端点中心がビア形状上に配置されているかのチェック。

- Track/Arc to Pad - トラック/アークセグメントの中心線、または端点中心がパッド形状上に配置されているかのチェック。

- Via to Pad - ビア中心がパッド形状上に配置されているかのチェック。

- Via to Via - あるビアの中心が別のビア形状上に配置されているかのチェック。

- Polygon to Track/Arc - トラック/アークセグメントの中心線、または端点中心がポリゴンによりオーバーラップされているかのチェック。

- Polygon to Pad/Via - Pad/Via がポリゴンへダイレクト接続を使用している場合に、Pad/Via の中心がポリゴンによりオーバーラップされているかのチェック。

ルール適用(Rule Application)

Batch DRC。

注記(Notes)

-

不十分な接続は、設計空間上で詳細違反マーカー

により示され、対応するメッセージが Messages パネルに表示されます。

により示され、対応するメッセージが Messages パネルに表示されます。

-

該当する場合、ネット内の未接続オブジェクト間に接続ラインが描画され、未配線ネット長に関するデータが PCB panel(Nets mode)に反映されます。

-

一部の DRC チェックは、動作させるために Un-Routed Net ルールを Batch 有効にする必要があります。

-

Printed Electronics では、レイヤー遷移にビアはnot不要であり、配線済みネットからビアを削除しても、ネットアナライザはネットが分断されていないと認識します。Layer Stack Manager で Printed Electronics オプションが有効になっている場合、ボードは Printed Electronics と定義されます。Printed Electronics の詳細を参照してください。

-

このルールは Wire Bonding にも適用されます。同一ネットのダイパッド、ボンドワイヤ、および/または銅箔オブジェクト間に接続がない場合に違反となります。

未接続ピン

デフォルトルール:不要

このルールは、ネットが割り当てられておらず、接続トラックも存在しないピンを検出します。

制約

なし

ルール適用

オンラインDRCおよびバッチDRC。

変更されたポリゴン

デフォルトルール:必要

このルールは、まだシェルブ(shelved)されたままのポリゴン、および/または変更されているが未リポア(再ポア)状態のポリゴンを検出します。

制約

変更されたポリゴン ルールのデフォルト制約

- Allow shelved - 有効な場合、このデザインルールのスコープ内にあり、現在シェルブされているすべてのポリゴンは違反としてフラグされません。

- Allow modified - 有効な場合、このデザインルールのスコープ内にあり、現在変更されているが未リポアのすべてのポリゴンは違反としてフラグされません。

ルール適用

オンラインDRCおよびバッチDRC。

沿面距離

デフォルトルール:不要

このルールは、非めっき穴、切り欠き(カットアウト)、および基板外形の周囲を通って、基板表面上で対象信号間の沿面距離をテストします。

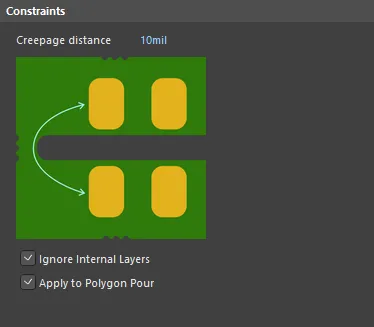

制約

沿面距離ルールのデフォルト制約

- Creepage distance – 第1オブジェクト上の任意の点が、第2オブジェクト上の任意の点からの距離以下(または同等)である場合にルール違反としてフラグされます。

- Ignore Internal Layers – ルールを外層のみに適用するためにこのオプションを使用します。

- Apply to Polygon Pour – スコープされたポリゴンにルールを適用するためにこのオプションを使用します。

ルール適用

オンラインDRC、バッチDRC、およびオートルーティング中。

注記

-

沿面距離ルールは、デフォルトではオンライン/バッチのデザインルールチェックで有効になっていません。Design Rule Checker dialog(Tools » Design Rule Check、Electricalカテゴリ)でオンライン/バッチチェックを有効にしてください。

-

ルール違反の表示も設定が必要な場合があります。PCB Editor - DRC Violation Display page (Preferencesダイアログ)で、Violation Details(ローカライズされた違反情報)および/または Violation Overlay(違反しているオブジェクト全体のハイライト)を有効にします。

-

このルールは、対象ネット上の最も近い点を特定し、X、Y、Z各平面でそれらの間の距離をチェックします。

-

パッド配置によって基板スロットを作成した場合、ソフトウェアはめっきバレルが導通するとみなして沿面距離をそれに応じて短くするため、パッドプロパティでPlatedオプションが無効になっていることを確認してください。

-

ポリゴンポアと他のオブジェクトが、Apply to Polygon Pour オプションを有効にした沿面距離デザインルールおよびClearance design ruleの両方でスコープされている場合、両ルールが考慮され、ポリゴンをポアする際にはより大きい値が適用されます。たとえば、沿面距離ルールの制約値がクリアランスルールより大きい場合、この大きい値が適用されます。

AI で翻訳

AI で翻訳