Electrical Rule Types

Altium Essentials: PCB Design Rules Creation

This content is part of the official Altium Professional Training Program. For full courses, materials and certification, visit Altium Training.

Electrical 카테고리의 설계 규칙은 아래에 설명되어 있습니다.

Electrical 카테고리의 설계 규칙.

Clearance

기본 규칙: 필수

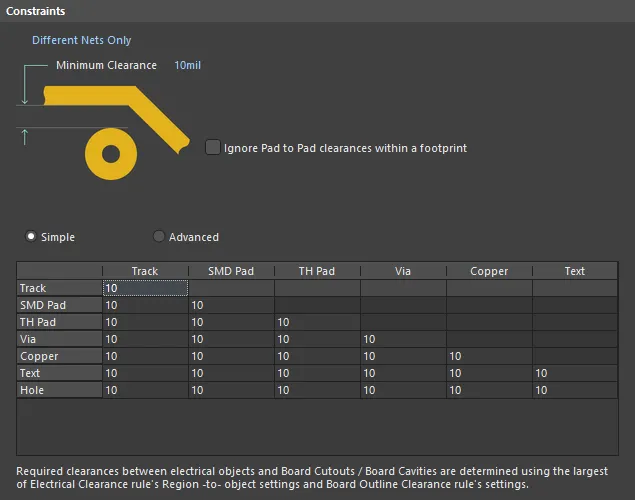

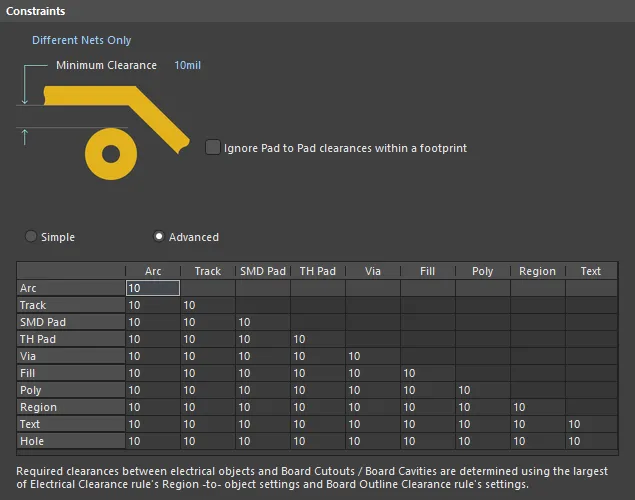

이 규칙은 구리 레이어에서 임의의 두 프리미티브 객체 사이에 허용되는 최소 간격(clearance)을 정의합니다. 간격에 대해 단일 값을 지정할 수도 있고, 전용 Minimum Clearance Matrix를 사용하여 객체 쌍 조합별로 서로 다른 간격을 지정할 수도 있습니다. 후자의 방식은 규칙 스코핑(rule-scoping)과 결합될 때, 가장 엄격한 간격 요구사항까지도 충족할 수 있도록 간결하고 목적에 맞는 간격 규칙 세트를 구성할 수 있는 유연성을 제공합니다.

Constraints

규칙 스코프는 객체 집합을 반환하며, 아래에 상세히 설명된 제약 조건이 그 객체 집합에 적용됩니다:

-

Connective Checking - 규칙 스코프가 반환한 넷(net) 객체 집합은 다음과 같은 방식으로 추가로 좁힐 수 있습니다:

-

Different Nets Only- 서로 다른 넷에 속한 임의의 두 프리미티브 객체 사이에 제약 조건이 적용됩니다(예: 서로 다른 두 넷의 두 트랙). -

Same Net Only- 동일한 넷에 속한 임의의 두 프리미티브 객체 사이에 제약 조건이 적용됩니다(예: 동일 넷의 비아와 패드 사이, 또는 동일 넷의 두 트랙 세그먼트 사이). -

Any Net- 설계 내 임의의 넷에 속한 임의의 두 프리미티브 객체 사이에 제약 조건이 적용됩니다. 이는 세 가지 옵션 중 가장 포괄적이며, 객체가 동일 넷에 속하는 경우와 서로 다른 넷에 속하는 경우를 모두 포함합니다. - Different Differential Pair - 서로 다른 차동 페어(differential pair)에 속한 서로 다른 넷의 임의의 두 프리미티브 객체 사이에 제약 조건이 적용됩니다(예: DiffPair1의 트랙과 DiffPair2의 트랙). 이 규칙은 동일한 차동 페어 내 두 넷의 프리미티브 사이에는 적용되지 않습니다(예: DiffPair1_P 및 DiffPair1_N). 이 제약 조건을 사용하여 차동 페어 간 간격을 구성합니다.

-

Same Differential Pair - 동일한 차동 페어 내 서로 다른 넷에 속한 임의의 두 프리미티브 객체 사이에 제약 조건이 적용됩니다(예: TX_P의 트랙과 TX_N의 트랙). 이 제약 조건을 사용하여, 차동 페어의 두 넷이 일반 간격에서 허용하는 것보다 더 가깝게 배치되어야 할 때의 간격을 구성합니다.

-

- Ignore Pad to Pad Clearances within a footprint - 동일한 컴포넌트 풋프린트 내 패드 간 간격을 무시할지 여부를 지정하려면 이 옵션을 켜거나 끕니다. 이 옵션은 기본적으로 비활성화되어 있습니다.

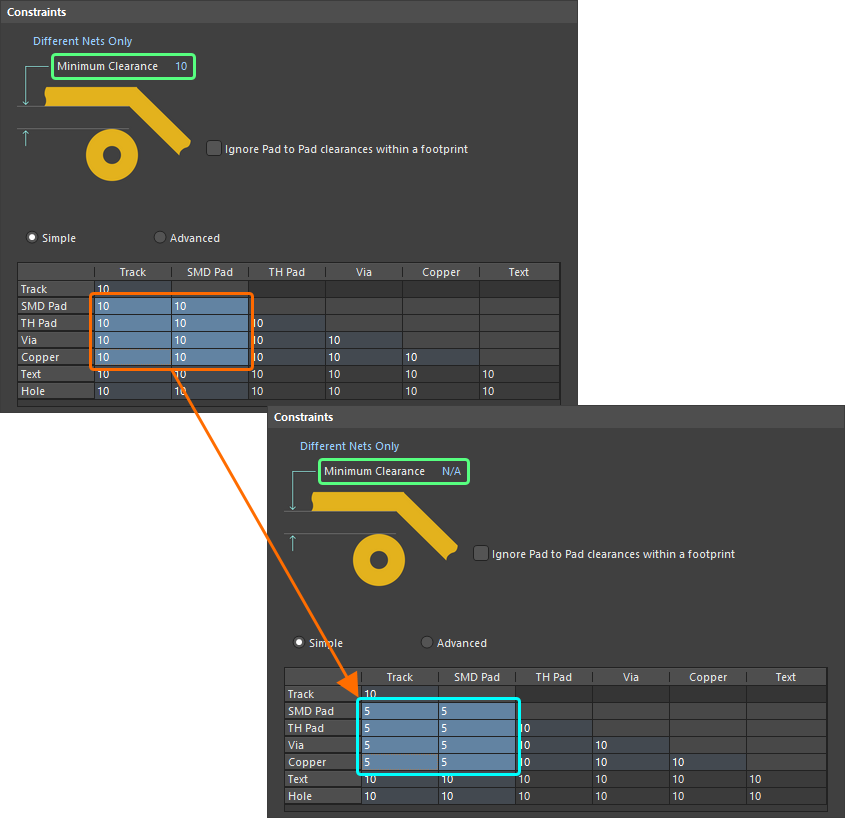

- Minimum Clearance - 필요한 최소 간격 값입니다. 여기에 입력한 값은 Minimum Clearance Matrix의 모든 셀에 복제됩니다. 반대로, 매트릭스에서 하나 이상의 객체 쌍 조합에 대해 다른 간격 값을 입력하면, Minimum Clearance 제약 조건은 N/A(으)로 변경되어 단일 간격 값이 전체에 일괄 적용되지 않음을 반영합니다.

- Minimum Clearance Matrix - 설계에서 다양한 객체-객체 간 간격 조합에 대해 간격을 미세 조정할 수 있는 기능을 제공합니다.

Clearance Matrix 작업하기

많은 사용자에게 Track과 Arc 프리미티브는 큰 차이가 없습니다. 또한 Fill, Region, Polygon 객체의 경우 대부분의 사용자는 이를 더 많은 ‘구리(copper)’로만 인식합니다. 이를 고려하여 Clearance 규칙의 최소 간격 매트릭스는 두 가지 모드로 동작하도록 개선되었습니다:

- Simple - 이 모드에서는 Track 및 Arc 객체(Track Keepout 및 Arc Keepout 객체 포함)가 단일 Track 항목으로 결합됩니다. Fill, Poly, Region 객체(Fill Keepout 및 Region Keepout 객체 포함)는 단일 Copper 항목으로 결합됩니다. Simple 모드는 기존 설계를 열든 새 설계를 열든 관계없이 기본 모드입니다.

- Advanced - 이 모드는 모든 객체가 표시되는 전통적인 매트릭스입니다.

매트릭스에서 간격 값을 정의하는 방법은 다음과 같습니다:

- 단일 셀 편집 - 특정 객체 쌍 조합에 대한 최소 간격을 변경합니다. 편집할 셀을 클릭하여 선택합니다.

-

다중 셀 편집 - 여러 객체 쌍 조합에 대한 최소 간격을 변경합니다:

- 열에서 여러 셀을 선택하려면 Ctrl+Click, Shift+Click, Click+Drag를 사용합니다.

- 행에서 연속된 여러 셀을 선택하려면 Shift+Click, Click+Drag를 사용합니다.

- 여러 행과 열에 걸쳐 연속된 여러 셀을 선택하려면 Click+Drag를 사용합니다.

- 행 헤더를 클릭하면 해당 행의 모든 셀을 빠르게 선택할 수 있습니다.

- 열 헤더를 클릭하면 해당 열의 모든 셀을 빠르게 선택할 수 있습니다.

필요한 선택(단일 셀 또는 다중 셀)을 완료한 후에는, 원하는 새 값을 입력하기만 하면 현재 값을 변경할 수 있습니다. 새로 입력한 값을 적용하려면 다른 셀을 클릭하거나 Enter를 누르십시오. 선택된 모든 셀이 새 값으로 업데이트됩니다.

다중 셀 편집 예시. 이제 하나 이상의 객체 쌍 조합에 대해 서로 다른 간격 값이 존재하므로, Minimum Clearance 제약 조건이 N/A(으)로 변경되어 모든 객체-객체 간 간격 조합에 단일 간격 값이 더 이상 적용되지 않음을 반영합니다.

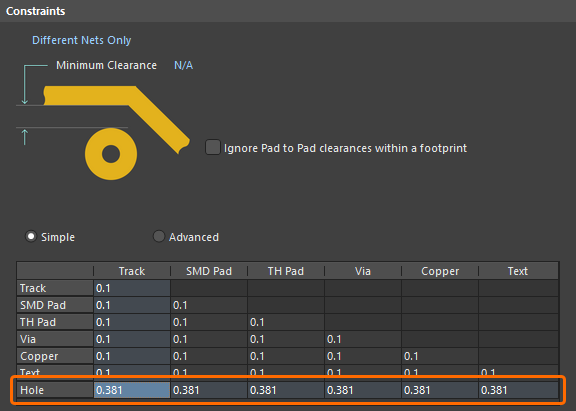

Hole-to-Object Clearance Checking

설계자는 드릴 홀의 가장자리와 신호 레이어의 인접한 구리 객체 사이의 간격을 검사할 수 있습니다. 이는 보드 제작 중 드릴이 흔들릴 가능성으로 인해 발생할 수 있는 문제를 방지하기 위해, 드릴 홀에 너무 가까이 트랙이 라우팅되는 것을 예방하는 데 특히 유용합니다. Clearance 규칙의 최소 간격 매트릭스 하단 행은 원하는 간격을 정의하는 데 사용됩니다.

설계에서 드릴 홀 가장자리에 너무 가까운 모든 구리 객체를 잡아낼 수 있도록 간격 값을 설정합니다.

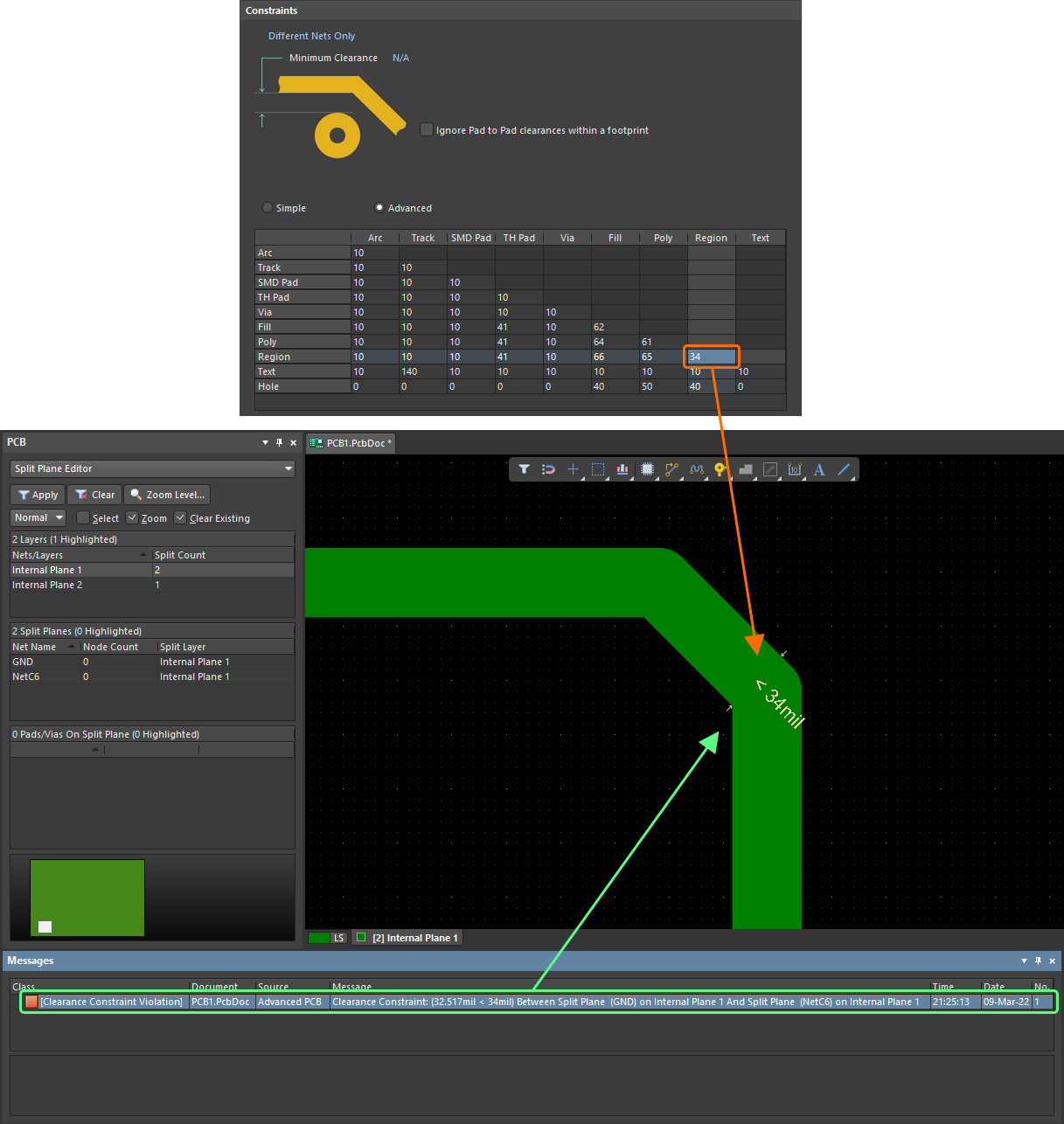

스플릿 플레인 클리어런스 검사

설계자는 내부 플레인 레이어의 스플릿 플레인 영역 간 클리어런스도 검사할 수 있습니다. 클리어런스 정의 방식은 최소 클리어런스 매트릭스를 사용하는 모드에 따라 달라집니다:

- Simple mode - Copper-Copper 셀을 사용하여 필요한 스플릿 플레인-스플릿 플레인 클리어런스 값을 지정합니다.

- Advanced mode - Region-Region 셀을 사용하여 필요한 스플릿 플레인-스플릿 플레인 클리어런스 값을 지정합니다.

위반은 다음 형태로 표시됩니다:

Clearance Constraint: (<CurrentClearance> < <DefinedClearance>) Between Split Plane (<NetName>) on <InternalPlaneLayerName> And Split Plane (<NetName>) on <InternalPlaneLayerName>,

예:

Clearance Constraint: (32.36mil < 34mil) Between Split Plane (GND) on Internal Plane 1 And Split Plane (NetC6) on Internal Plane 1

내부 레이어에서 스플릿 플레인 영역 간 클리어런스를 검사하는 경우입니다. 이 경우, 매트릭스의 Advanced 모드를 사용해 클리어런스를 정의하고 있으므로 Region-Region 셀에 34mil의 클리어런스 값이 입력되었습니다.

차동 페어 클리어런스 검사

차동 페어는 고유한 설계 과제를 가지며, 종종 특정 within-pair 클리어런스와 pair-to-pair 클리어런스가 필요하고, 경우에 따라 pair-to-all other nets, 클리어런스를 제어하기 위한 세 번째 규칙이 필요할 수도 있습니다. 이를 지원하기 위해 Constraints 영역에는 Same Differential Pair 및 Different Differential Pair 옵션을 선택할 수 있는 드롭다운이 포함되어 있습니다.

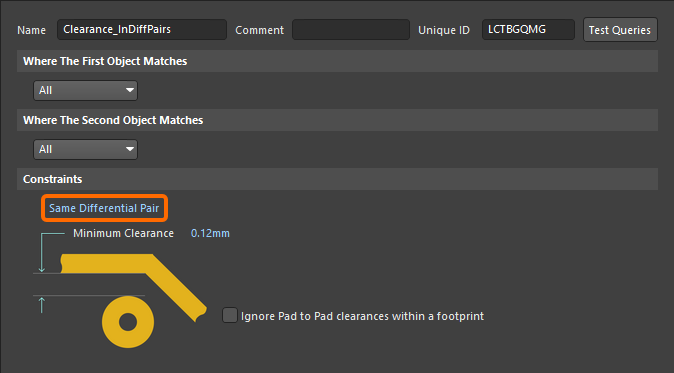

예를 들어, 차동 페어 내의 넷들이 일반 보드 클리어런스보다 더 타이트한 클리어런스를 필요로 한다면, 아래와 같이 Same Differential Pair 제약 옵션을 사용해 이를 달성할 수 있습니다. 규칙 스코프가 설계 내 All 넷 오브젝트에 적용되더라도, Constraint 설정은 적용 대상을 Same Differential Pair 내의 오브젝트로만 제한한다는 점에 유의하세요.

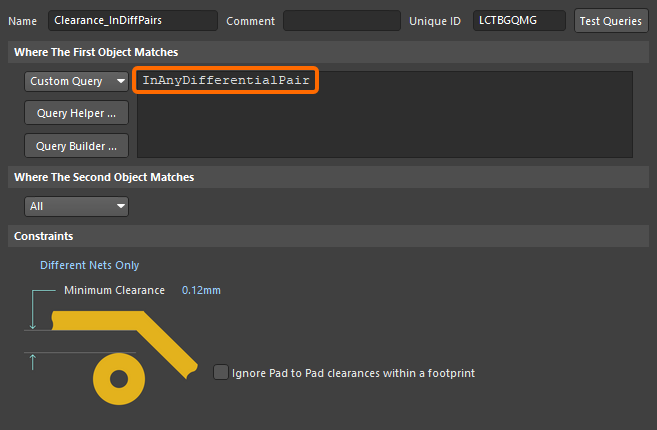

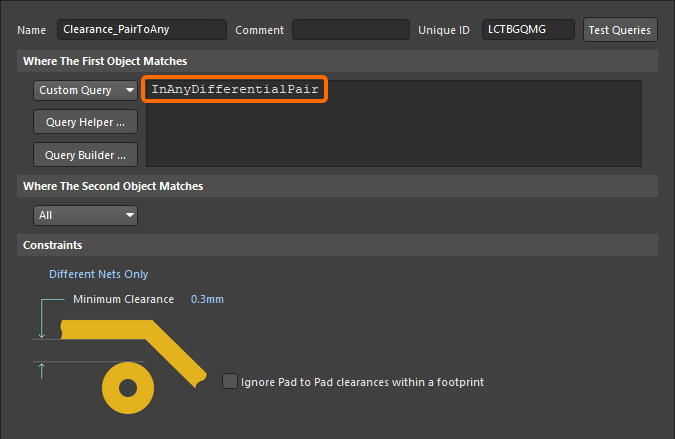

아래와 같이 규칙 스코프를 차동 페어 오브젝트(예: InAnyDifferentialPair)에만 적용하도록 설정해도 동일한 결과를 얻을 수 있습니다. 다만 이 규칙은 차동 페어에 속한 넷과 설계 내 다른 어떤 넷 오브젝트 사이에도 적용되므로, 이 접근은 DiffPairNet-to-DiffPairNet 및/또는 DiffPairNet-to-Any 요구사항을 정의하는 더 높은 우선순위 규칙이 다른 곳에 있는 경우에만 사용해야 합니다. 이 접근을 사용하는 경우, 차동 페어 규칙의 Priority도 올바르게 구성해야 하며, 더 타이트한 클리어런스 요구사항을 가진 규칙이 더 높은 우선순위를 가져야 합니다.

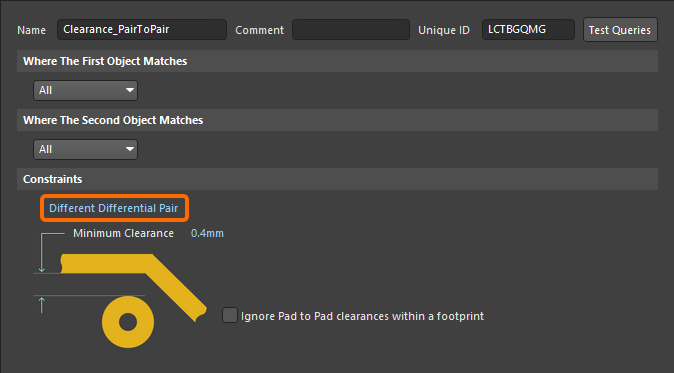

유사한 접근으로 차동 페어 between 클리어런스도 제어할 수 있습니다. 아래 이미지는 Different Differential Pair 제약을 사용해 이를 달성하는 방법을 보여줍니다.

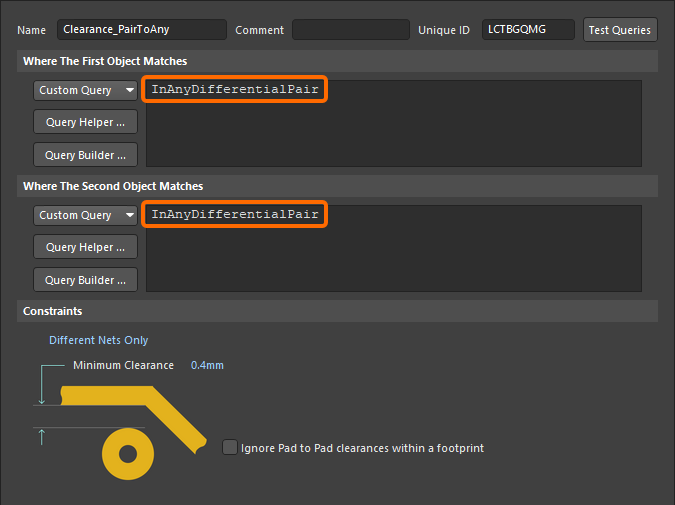

이전 예와 마찬가지로, Different Differential Pairs 제약 대신 규칙 스코프를 사용해도 달성할 수 있습니다. 규칙 우선순위는 더 타이트한 클리어런스 요구사항을 가진 규칙이 더 높은 우선순위를 갖도록 구성해야 한다는 점을 기억하세요.

차동 페어 넷에서 다른 어떤 넷 오브젝트로의 서로 다른 클리어런스를 정의하려면, 다음 규칙을 사용할 수 있습니다.

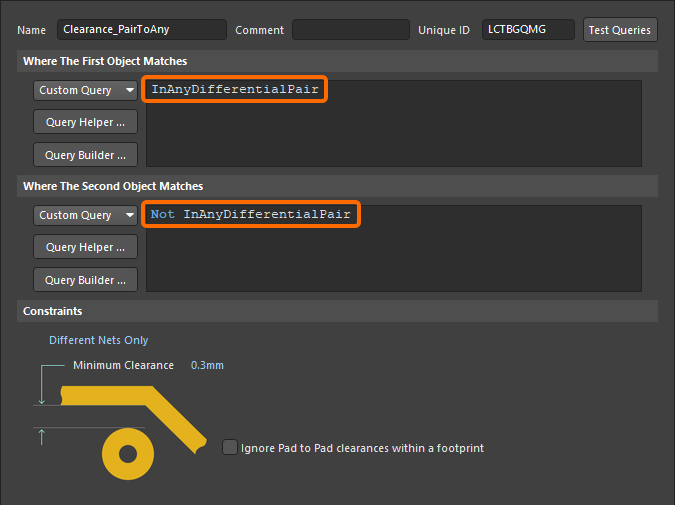

아래와 같이, 차동 페어 오브젝트와 비-차동 페어 오브젝트 사이에만 적용되도록 더 세분화할 수도 있습니다.

Differential Pair Routing에 대해 더 알아보세요. Differential Pair design rules의 스코핑에 대해 더 알아보세요.

규칙 적용

Online DRC, Batch DRC, 대화형 라우팅 #, 자동 라우팅 #, 그리고 폴리곤 배치.

참고

- # DRC는 어떤 종류의 오브젝트든 어떤 종류의 오브젝트든, 어떤 형태의 규칙 스코핑을 사용하더라도 클리어런스를 테스트할 수 있지만, 라우팅 엔진은 이 수준의 세분성을 지원하지 않습니다. 예를 들어, 기본 클리어런스 규칙이 모든 트랙에 대해 1 mm 클리어런스를 요구하고, 더 높은 우선순위 규칙이 길이가 10 mm를 초과하는 트랙에 대해 2 mm 클리어런스를 요구할 수 있습니다. 이 상황에서 대화형 라우팅 엔진은 기본 클리어런스 규칙을 따르고, 더 높은 우선순위의 ‘길이 10 mm 초과’ 규칙은 무시합니다. 또 다른 예는 코너에서 아크로 라우팅하는 경우입니다. 클리어런스 규칙이 트랙보다 아크에 더 큰 클리어런스를 지정하고, 코너에서 아크로 대화형 라우팅을 수행하면, 대화형 라우팅 엔진은 아크 설정을 무시하고 트랙 설정을 따르며, 코너 아크를 트랙 세그먼트와 동일한 클리어런스로 배치합니다. 이 두 예 모두에서 라우팅이 완료되는 즉시 Online DRC가 해당 상황을 위반으로 표시합니다.

-

규칙의 제약을 정의할 때, Connective Checking 옵션은 일반적으로

Different Nets Only로 설정됩니다.Same Net Only또는Any Net를 사용할 수 있는 예로는, 동일 넷 또는 다른 넷에서 비아가 패드나 다른 비아에 너무 가깝게 배치되었는지 테스트하는 경우 등이 있습니다. - 최소 클리어런스 매트릭스는 지정된 커넥티브 검사 방법과 무관하게 적용됩니다. 동일 넷 내 오브젝트 간에, 서로 다른 넷의 오브젝트에 대해 정의된 값과 다른 클리어런스가 필요하다면, 필요에 맞게 별도의 클리어런스 규칙을 반드시 정의하세요.

- 클리어런스 매트릭스의 적용 범위는 규칙 스코핑에 따라 달라집니다. 예를 들어 스코핑이 ALL-ALL인 경우, 매트릭스의 모든 셀이 적용됩니다(즉, 가능한 모든 오브젝트 페어링). 하지만 스코핑이 IsVia-IsTrack로 설정되어 있다면, Via-Track 오브젝트 페어링에 해당하는 단일 셀만 적용되며, 매트릭스의 다른 모든 셀은 사용되지 않습니다.

-

폴리곤에 대한 클리어런스 규칙을 정의할 때, 규칙은 폴리곤 자체가 아니라 폴리곤을 구성하는 프리미티브에 실제로 적용됩니다. 이 경우 Full Query에는

IsPolygon(또는IsPoly) 대신 키워드 항목InPolygon(또는InPoly)를 포함해야 합니다. 또한 특정 폴리곤 클리어런스 규칙이 효과를 가지려면, 어떤 일반 클리어런스 규칙보다도 더 높은 우선순위를 부여해야 합니다. - 라우팅(및 유사한 작업) 중에는 규칙 엔진이 편집 지점 주변의 장애물을 지속적으로 확인합니다. 스캔되는 영역에는 프리미티브의 영역과 해당 프리미티브 주변에 요구되는 클리어런스 영역이 포함됩니다. 즉, 규칙에서 정의한 클리어런스가 클수록 스캔해야 하는 영역이 커지고, 그만큼 작업 속도는 느려집니다. 큰 클리어런스가 소수의 객체에만 필요한 경우, 해당 객체들에 대해 큰 클리어런스 규칙을 정의하는 대신 그 주변에 keepout을 추가하면 라우팅 엔진이 느려지는 것을 피할 수 있습니다.

- Dielectric Shapes Generator ( Printed Electronics의) Auto 모드에서 사용할 때, 유전체(dielectric) 형상은 적용 가능한 Clearance Constraint 설계 규칙의 요구사항을 만족하도록 자동으로 확장됩니다.

- Printed Electronics에서는 net-to-net 클리어런스가 동일 레이어에서만이 아니라 모든 레이어에서 테스트됩니다.

단락(Short-Circuit)

기본 규칙: 필수

이 규칙은 구리(신호 및 플레인) 레이어의 프리미티브 객체 간 단락을 테스트합니다. 서로 다른 net 이름을 가진 두 객체가 접촉하면 단락이 존재하는 것으로 간주합니다.

제약 조건(Constraints)

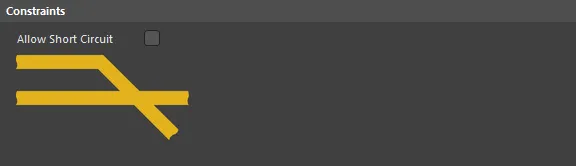

Short-Circuit 규칙의 기본 제약 조건

Allow Short Circuit - 규칙의 두 스코프(Full Query)에 해당하는 대상 net들이 서로 단락될 수 있는지 여부를 정의합니다. 예를 들어 설계 내에서 두 개의 그라운드 시스템을 연결하는 등 서로 다른 두 net을 의도적으로 쇼트시켜야 한다면, 이 옵션이 활성화되어 있는지 확인하십시오.

규칙 적용(Rule Application)

Online DRC, Batch DRC, 그리고 자동 라우팅 중.

참고(Notes)

-

Printed Electronics 설계 에서 서로 다른 net이 서로 다른 레이어에서 교차하면 단락으로 표시됩니다. 이러한 교차는 비전도성 레이어에 유전체 패치를 배치하여 절연합니다.

-

이 규칙은 Wire Bonding에도 적용됩니다. 본드 와이어가 다른 net의 다이 패드 또는 구리에 연결되거나, 서로 다른 net의 본드 와이어 끝점들이 연결되면 위반이 발생합니다.

미라우팅 Net(Un-Routed Net)

기본 규칙: 필수

이 규칙은 규칙의 스코프(Full Query)에 해당하는 각 net의 완료 상태를 테스트합니다. net이 미완료인 경우, 완료된 각 구간(서브넷)과 라우팅 완료 상태가 함께 나열됩니다. 라우팅 완료는 다음과 같이 정의됩니다:

(connections complete / total number of connections) x 100

PCB Editor의 DRC 시스템은 일반적으로 해당 net의 모든 노드(컴포넌트 패드)가 net 인지 설계 객체(트랙, 아크, 패드, 비아, 폴리곤)를 통해 연결되어 있으면 그 net이 라우팅된 것으로 봅니다. 이러한 객체들은 서로 접촉하면 연결된 것으로 간주합니다. 그러나 단순히 “닿기만” 하는 것은 소프트웨어상 연결로 인식되더라도, 보드 제작 단계에서는 이러한 ‘연결’ 중 일부가 취약하여 심각한 문제를 일으킬 수 있습니다. 특히 예를 들어 연속된 두 트랙 세그먼트, 또는 패드/비아로 들어가는 트랙이 아주 약간만 접촉하는 경우가 그렇습니다. 이러한 연결은 흔히 ‘Bad Connections’, ‘Poor Connections’, 또는 ‘Incomplete Connections’라고 부릅니다. 이 규칙은 이러한 불량 연결을 테스트하도록 구성할 수도 있습니다.

제약 조건(Constraints)

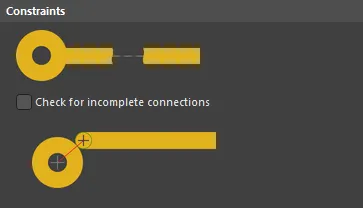

Un-Routed Net 규칙의 기본 제약 조건

Check for incomplete connections - 이 옵션을 활성화하면, 적용 가능한 설계 객체 간 연결성에 대해 다음의 추가 검사가 수행됩니다:

- Track/Arc to Track/Arc - 연결되는 트랙/아크 세그먼트 끝의 중심선 또는 중심점이 일치하는지 확인.

- Track/Arc to Via - 트랙/아크 세그먼트 끝의 중심선 또는 중심점이 비아 형상 위에 배치되었는지 확인.

- Track/Arc to Pad - 트랙/아크 세그먼트 끝의 중심선 또는 중심점이 패드 형상 위에 배치되었는지 확인.

- Via to Pad - 비아의 중심이 패드 형상 위에 배치되었는지 확인.

- Via to Via - 한 비아의 중심이 다른 비아의 형상 위에 배치되었는지 확인.

- Polygon to Track/Arc - 트랙/아크 세그먼트 끝의 중심선 또는 중심점이 폴리곤에 의해 오버랩되는지 확인.

- Polygon to Pad/Via - Pad/Via가 폴리곤에 직접 연결(Direct Connection)되는 경우, Pad/Via의 중심이 폴리곤에 의해 오버랩되는지 확인.

규칙 적용(Rule Application)

Batch DRC.

참고(Notes)

-

불량 연결은 설계 공간에서 상세 위반 마커

(으)로 표시되며, 해당 메시지는 Messages 패널에 표시됩니다.

(으)로 표시되며, 해당 메시지는 Messages 패널에 표시됩니다.

-

해당되는 경우, net 내에서 연결되지 않은 객체들 사이에 연결선이 그려지며, 미라우팅 net 길이에 대한 데이터는 PCB panel( Nets mode에서)에 반영됩니다.

-

일부 DRC 검사는 동작을 위해 Un-Routed Net 규칙이 Batch 활성화되어 있어야 합니다.

-

Printed Electronics에서는 레이어 전환에 비아가 not 필요하지 않으므로, 라우팅된 net에서 비아가 제거되더라도 net analyzer는 해당 net이 끊어지지 않은 것으로 인식합니다. 보드는 Layer Stack Manager에서 Printed Electronics 옵션이 활성화되어 있을 때 Printed Electronics로 정의됩니다. Printed Electronics에 대해 더 알아보십시오.

-

이 규칙은 Wire Bonding에도 적용됩니다. 동일 net의 다이 패드, 본드 와이어 및/또는 구리 객체 사이에 연결이 없으면 위반이 발생합니다.

연결되지 않은 핀

기본 규칙: 필요하지 않음

이 규칙은 넷이 할당되지 않았고 연결 트랙도 없는 핀을 감지합니다.

제약

없음

규칙 적용

온라인 DRC 및 배치 DRC.

수정된 폴리곤

기본 규칙: 필요함

이 규칙은 아직 셸브(shelved) 상태이거나 수정되었지만 아직 리포어(repoured)되지 않은 폴리곤을 감지합니다.

제약

수정된 폴리곤 규칙의 기본 제약

- Allow shelved - 활성화된 경우, 이 설계 규칙의 범위에 포함되며 현재 셸브된 모든 폴리곤은 위반으로 표시되지 않습니다.

- Allow modified - 활성화된 경우, 이 설계 규칙의 범위에 포함되며 현재 수정되었지만 아직 리포어되지 않은 모든 폴리곤은 위반으로 표시되지 않습니다.

규칙 적용

온라인 DRC 및 배치 DRC.

연면거리(Creepage) 거리

기본 규칙: 필요하지 않음

이 규칙은 보드 표면을 따라(비도금 홀, 컷아웃을 통과하거나 보드 에지를 따라) 대상 신호 간의 연면거리(Creepage distance)를 검사합니다.

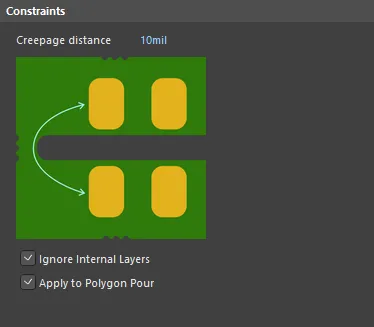

제약

연면거리(Creepage) 거리 규칙의 기본 제약

- Creepage distance – 첫 번째 객체의 어떤 지점이든 두 번째 객체의 어떤 지점으로부터의 거리가 지정 거리와 같거나 더 작으면 규칙 위반으로 표시됩니다.

- Ignore Internal Layers – 이 옵션을 사용하면 규칙이 외층(outer layers)에만 적용되도록 할 수 있습니다.

- Apply to Polygon Pour – 이 옵션을 사용하면 범위가 지정된 폴리곤(scoped polygons)에 규칙을 적용할 수 있습니다.

규칙 적용

온라인 DRC, 배치 DRC 및 자동 배선(autorouting) 중.

참고

-

연면거리(Creepage) 거리 규칙은 기본적으로 온라인 또는 배치 설계 규칙 검사에 대해 활성화되어 있지 않습니다. Design Rule Checker dialog (Tools » Design Rule Check, Electrical category)에서 온라인/배치 검사를 활성화하십시오.

-

규칙 위반 표시도 구성해야 할 수 있습니다. Preferences dialog의 PCB Editor - DRC Violation Display page 에서 Violation Details(현지화된 위반 정보) 및/또는 Violation Overlay(위반된 전체 객체 강조 표시)를 활성화합니다.

-

이 규칙은 대상 넷에서 가장 가까운 지점을 식별하고 X, Y, Z 평면에서 그 사이의 거리를 검사합니다.

-

패드를 배치하여 보드 슬롯을 만든 경우, 소프트웨어가 도금된 배럴(plated barrel)을 도전성으로 가정하여 연면거리를 그에 맞게 줄이므로 패드 속성에서 Plated 옵션이 비활성화되어 있는지 확인하십시오.

-

폴리곤 포어와 다른 객체가 Apply to Polygon Pour 옵션이 활성화된 연면거리(Creepage Distance) 설계 규칙과 Clearance design rule에 의해 함께 스코프되는 경우, 두 규칙이 모두 고려되며 폴리곤을 포어할 때 더 큰 값이 적용됩니다. 예를 들어 연면거리 규칙의 제약 값이 Clearance 규칙보다 크면, 이 더 큰 값이 적용됩니다.

AI로 번역됨

AI로 번역됨